Method for preparing ring opening product of epoxide by adopting microreaction device

A technology of epoxy compound and micro-reaction device, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, ether preparation, etc. Inaccurate control and other problems, to avoid the use of complex catalysts, short reaction residence time, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

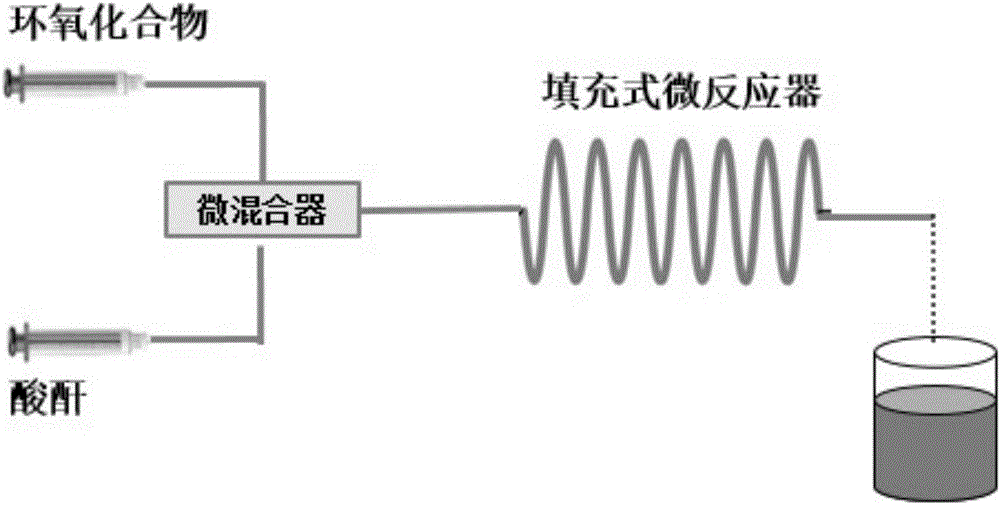

Method used

Image

Examples

Embodiment 1

[0027] Cyclohexane epoxy and acetic anhydride are mixed by a micro-mixer, injected into a packed micro-reactor filled with a solid catalyst HY zeolite, and reacted at 100°C for 8 minutes, wherein the molar ratio of the epoxy compound anhydride is 1:2, and the catalyst The molar ratio to epoxy compound is 0.02:1, and the output of the packed microreactor is passed through NaCO 3 Solution washing, water washing, and drying over anhydrous sodium sulfate, the epoxy compound ring-opened product was obtained, and the conversion rate of the raw material was 87%.

Embodiment 2

[0029] Epoxycyclohexane and propionic anhydride are mixed by a micro-mixer, injected into a packed micro-reactor filled with a solid catalyst HY zeolite, and reacted at 110°C for 10 minutes, wherein the molar ratio of the epoxy compound anhydride is 1:2, and the catalyst The molar ratio to epoxy compound is 0.02:1, and the output of the packed microreactor is passed through NaCO 3 Solution washing, water washing, and drying over anhydrous sodium sulfate, the epoxy compound ring-opened product is obtained, and the conversion rate of the raw material is 85%.

Embodiment 3

[0031] Epoxycyclohexane and butyric anhydride are mixed by a micro-mixer, injected into a packed micro-reactor filled with a solid catalyst HY zeolite, and reacted at 120°C for 10 minutes, wherein the molar ratio of the epoxy compound anhydride is 1:2, and the catalyst The molar ratio to epoxy compound is 0.03:1, and the output of the packed microreactor is passed through NaCO 3 Solution washing, water washing, and drying over anhydrous sodium sulfate, the epoxy compound ring-opened product is obtained, and the conversion rate of the raw material is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com