Patents

Literature

44 results about "Stearoyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging 5, 25 g in glass bottle Application Stearoyl chloride was used in the synthesis of 4-fluoroceramide.It was also used in the preparation of shimofuridin analogs: 2′-O-(4-O-stearoyl-alpha-L-fucopyranosyl)thymidine and -uridine.

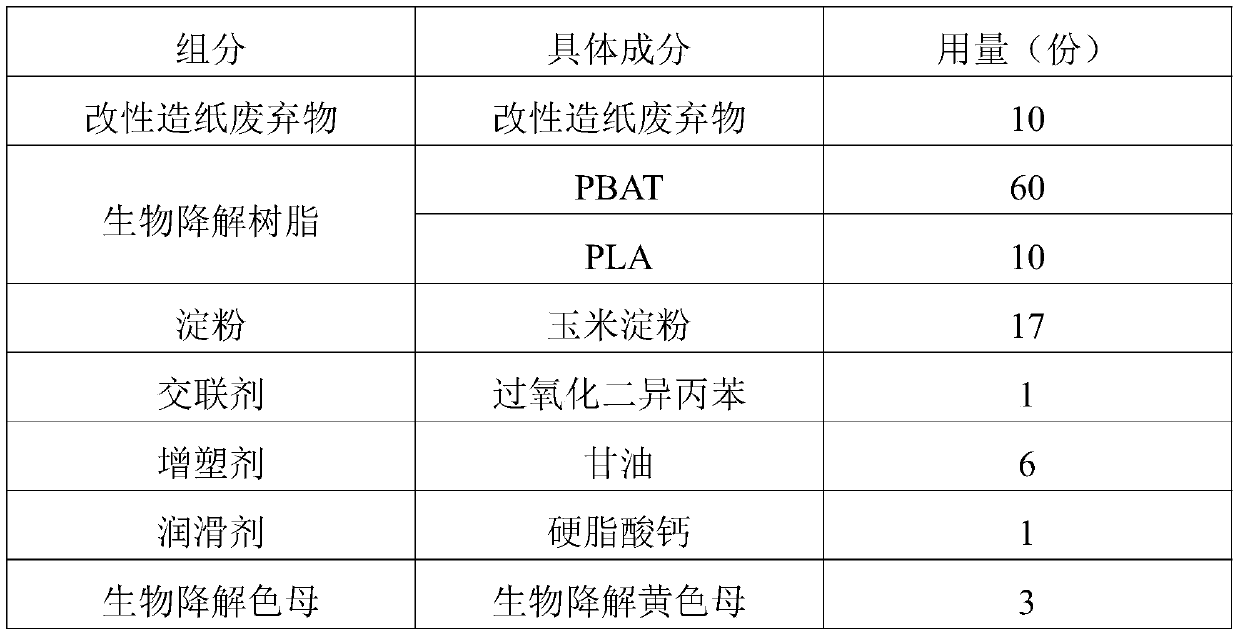

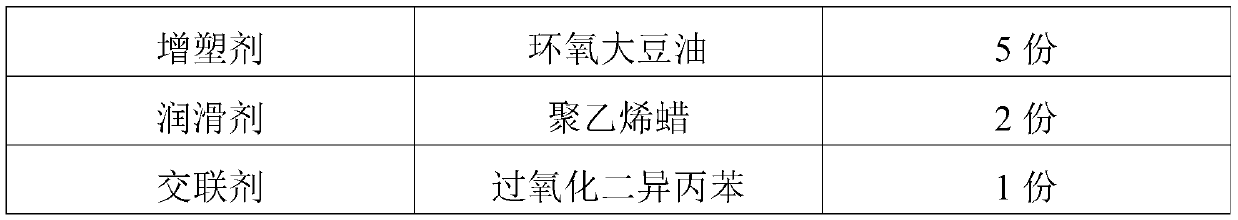

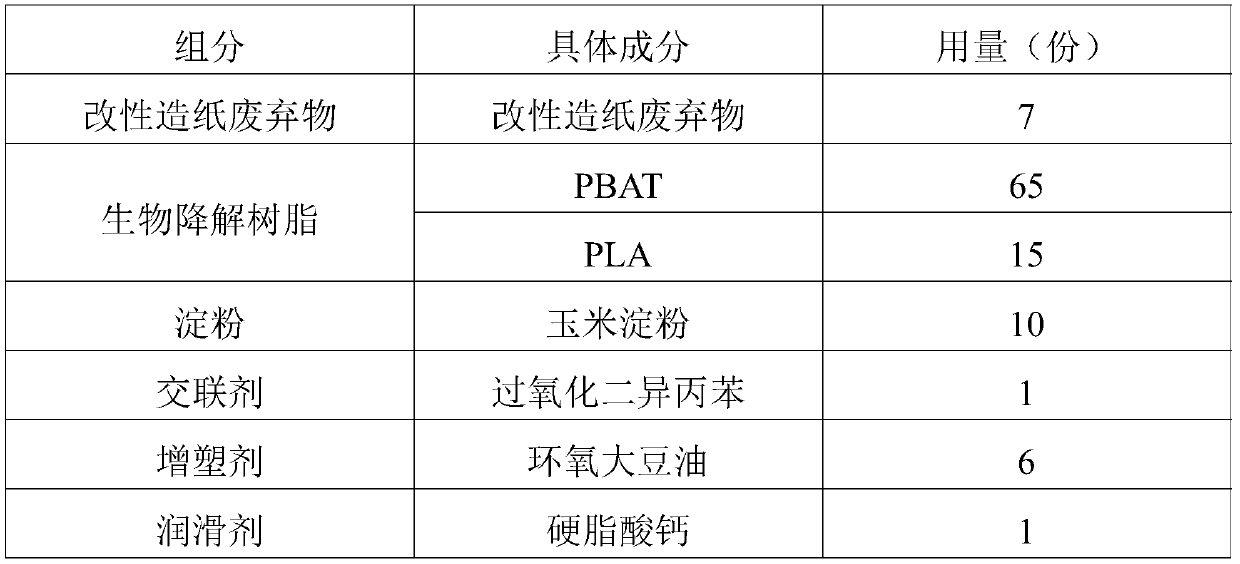

Application of raw material composition in preparation of biodegradable insect trapping plate

InactiveCN111234477AHigh tensile strengthHigh elongation at breakInsect catchers and killersBiotechnologyChloroacetyl chloride

The invention discloses an application of a raw material composition in preparation of a biodegradable insect trapping plate. The raw material composition comprises the following components in parts by weight: 5-20 parts of modified papermaking waste, 50-90 parts of a biodegradable resin and 1-10 parts of auxiliaries, wherein the modified papermaking waste comprises 100 parts of papermaking waste,1-50 parts of a modifier and 0.1-5 parts of a phase transfer agent, and the modifier is one or more of stearoyl chloride, acetyl chloride, benzoyl chloride, oxalyl chloride, chloroacetyl chloride andtrichloroacetyl chloride. The master batch of the biodegradable insect trapping plate and the biodegradable insect trapping plate can be completely degraded by microorganisms in the nature, so that the environment is not polluted, waste utilization can be achieved, and the cost is reduced. The modified papermaking waste is adopted, so that the compatibility of the modified papermaking waste and biodegradable resin can be effectively improved, and the tensile strength and elongation at break of the biodegradable insect trapping plate are improved. The insect trapping amount of the biodegradable insect trapping plate is obviously superior to that of a traditional PP insect trapping plate and that of a traditional PVC insect trapping plate.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

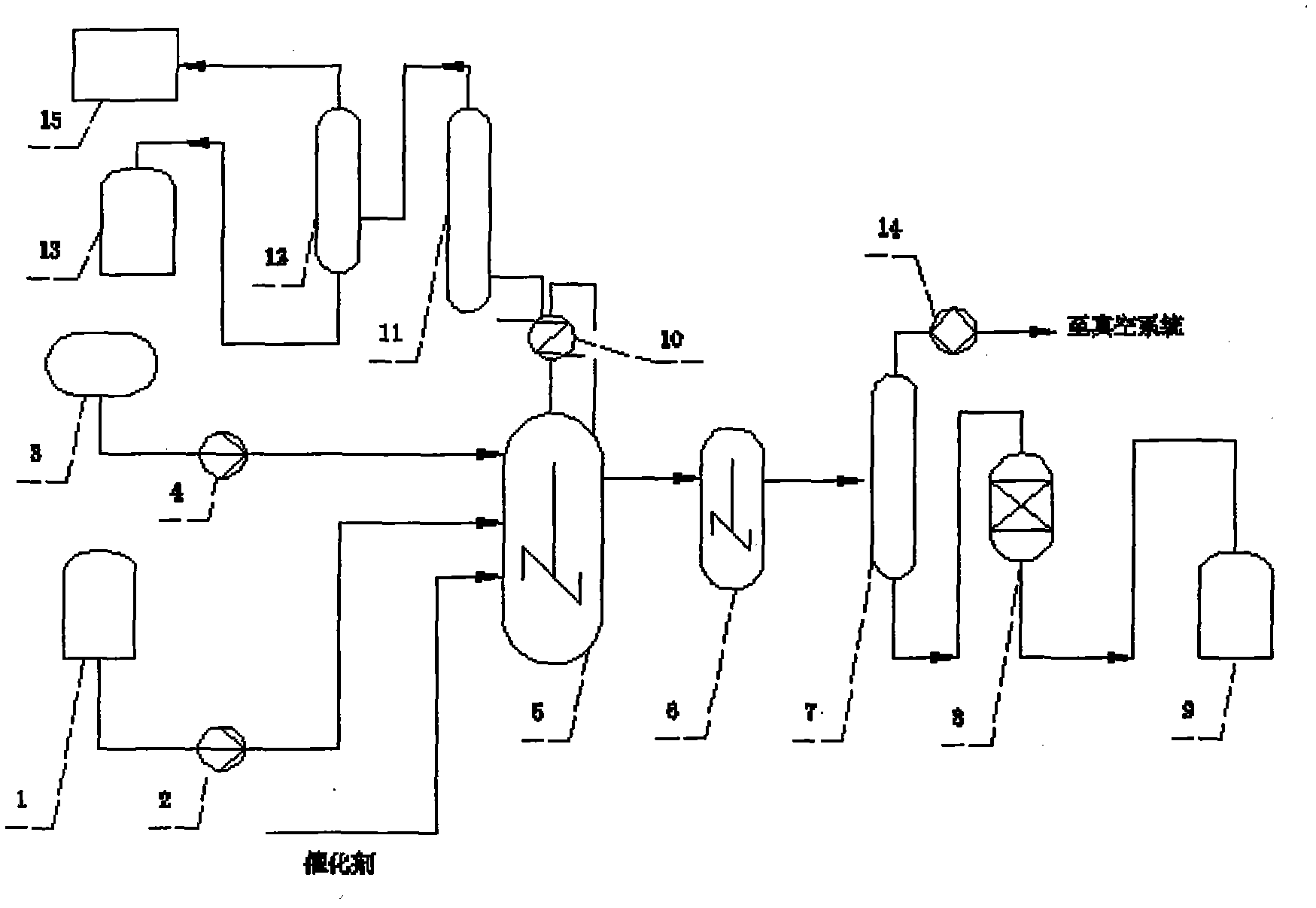

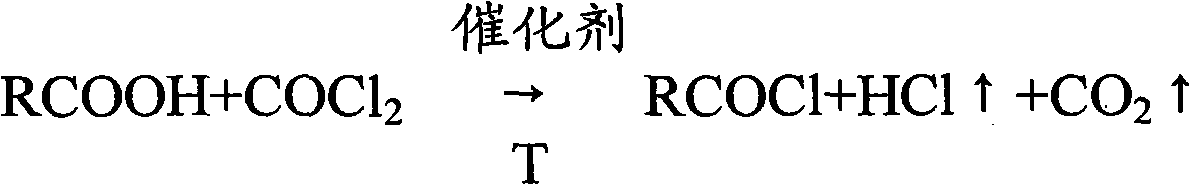

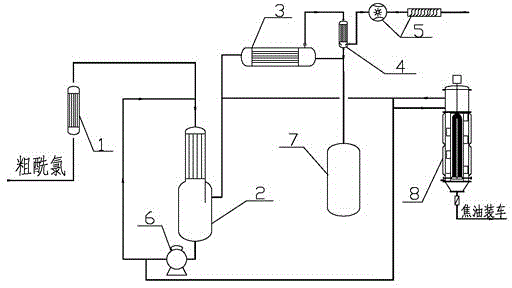

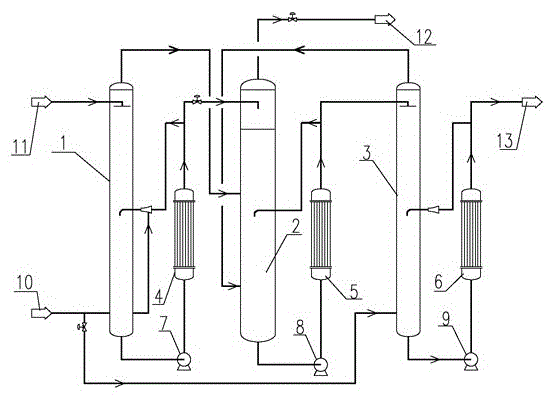

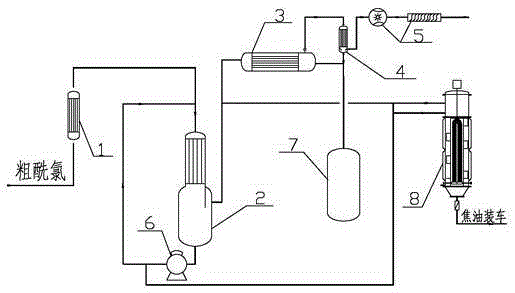

Method for producing stearoyl chloride and homologs thereof by liquid-phase phosgenation

InactiveCN102633620AIncrease the areaHigh speedOrganic compound preparationCarboxylic compound preparationGas phaseStearic acid

The invention relates to a method for producing stearoyl chloride and homologs thereof by liquid-phase phosgenation, which is characterized in continuous operation. The method comprises the following steps: simultaneously adding a raw material A, a catalyst and phosgene into a main photochemical reaction kettle (5), reacting in the main photochemical reaction kettle (5) and a photochemical reaction mature kettle (6), removing the phosgene by a negative pressure phosgene removal column (7), and decolorizing by a stearoyl chloride product decolorizing device (8) to continuously generate the stearoyl chloride product, wherein the raw material A is one of stearic acid and homologs thereof, or the mixture of two or three of the homologs. The invention solves the problems of long reaction time, low phosgene utilization ratio, multiple byproducts, low product purity, difficulty in absorbing and utilizing the generated HCl and CO2 gases, and the like in the existing technique for producing stearoyl chloride by gas-phase phosgenation, and provides a high-efficiency environment-friendly high-quality production technique of stearoyl chloride, homologs and homologic mixtures thereof.

Owner:甘肃银光聚银化工有限公司

Decoloring method of crude stearyl chloride

InactiveCN104592003AReduce wasteEasy to handleOrganic compound preparationCarboxylic compound preparationActivated carbonPhysical chemistry

The invention relates to a decoloring method of crude stearyl chloride which is characterized by comprising the following steps: pre-heating colored crude stearyl chloride to 80-200 DEG C in a pre-heater, sending the pre-heated colored crude stearyl chloride into an evaporator and circularly evaporating at 120-250 DEG C under an absolute pressure of 5Pa-50Kpa, pumping heavy components at the bottom of the evaporator into a tar concentrating devise by using a recycle pump to perform further concentration and evaporation, discharging the colored heavy component tar from the bottom for processing, cooling down gas phase at the top of the evaporator and the tar concentrating devise by using a condenser and a subcooler to obtain colorless pure stearyl chloride products. According to the invention, continuous decoloring of crude stearyl chloride containing heavy components is realized with high yield and low cost of process. Compared with activated carbon adsorption decoloring technology, the invention is applicable to removal of high boiling tar from heat sensitive materials due to low saturation of the product.

Owner:甘肃银光聚银化工有限公司

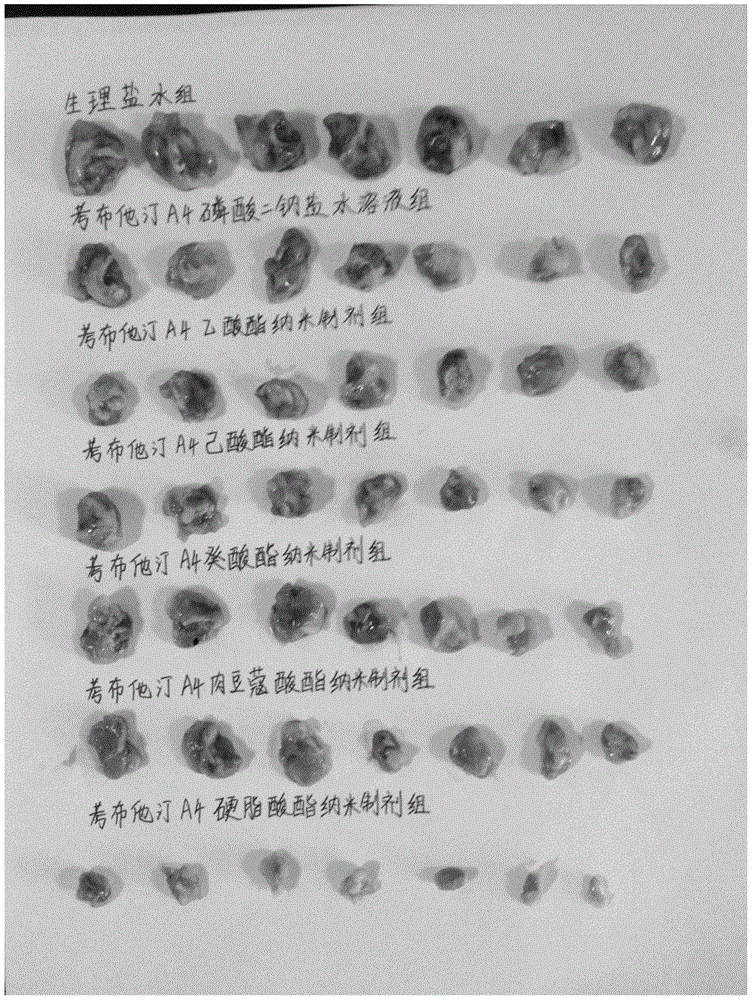

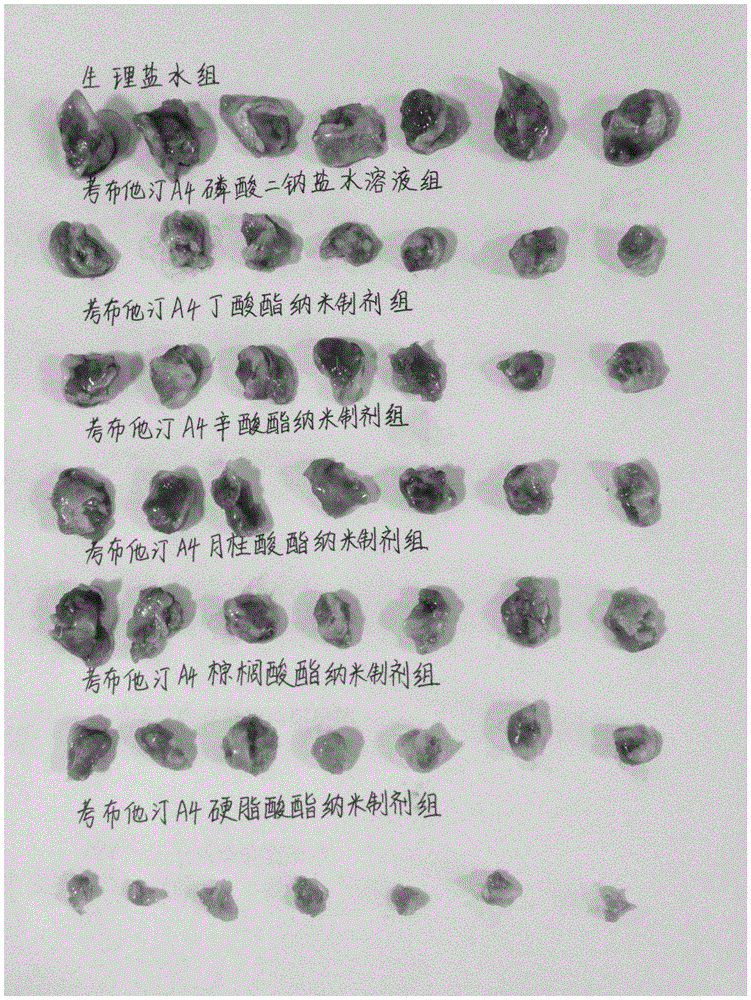

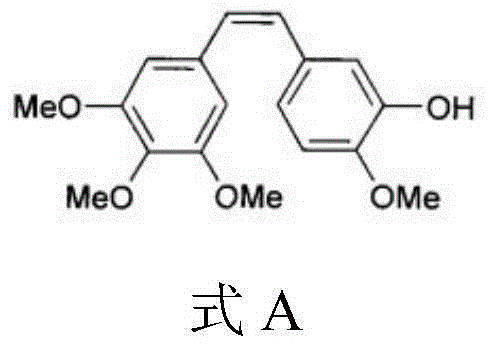

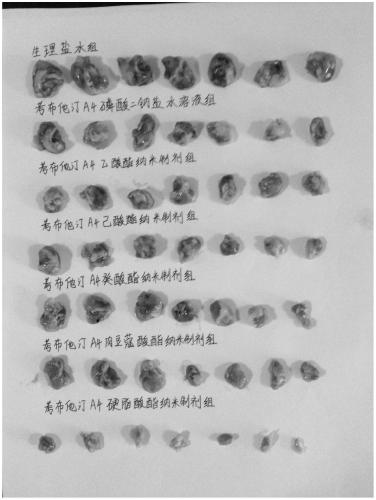

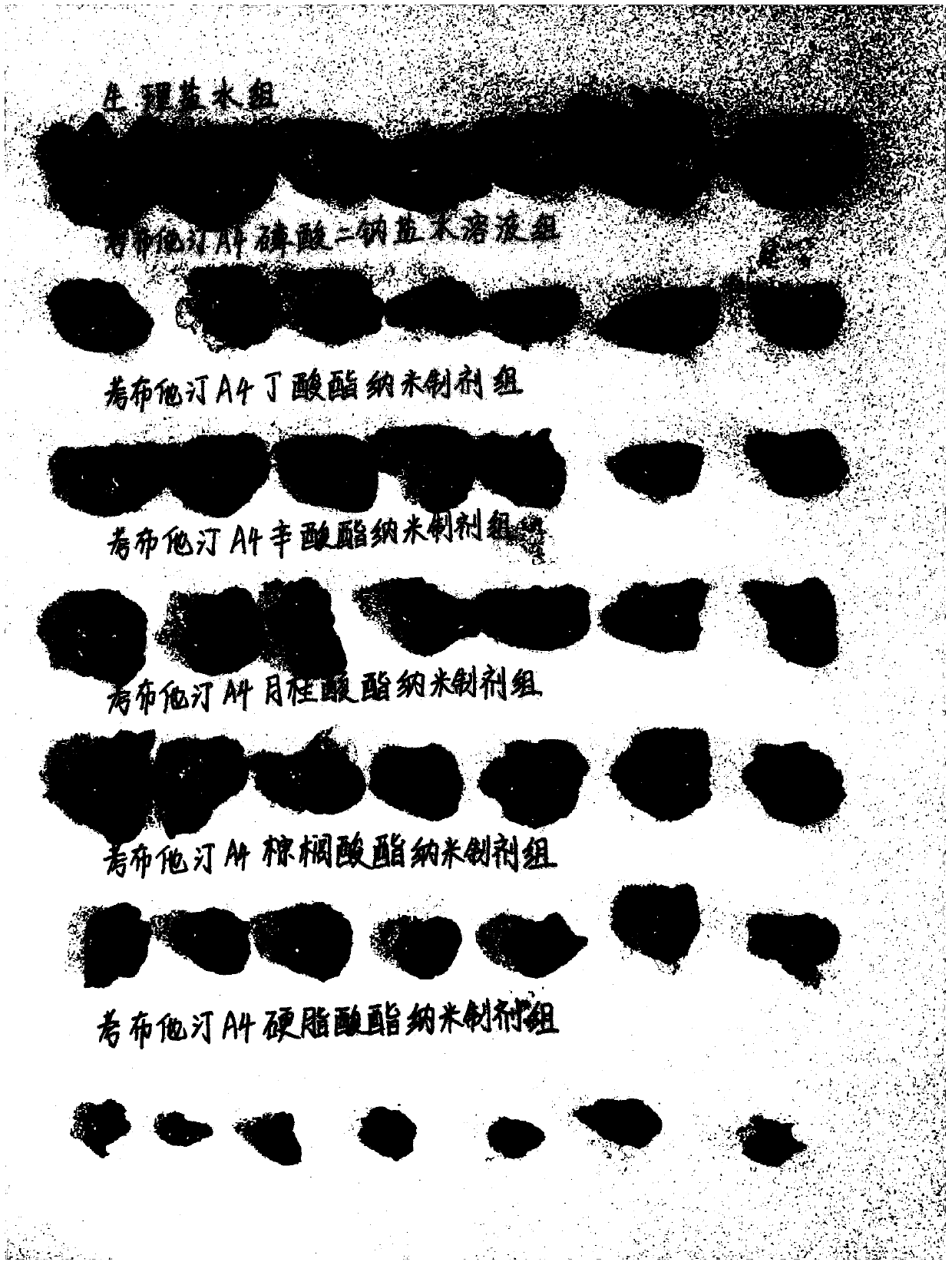

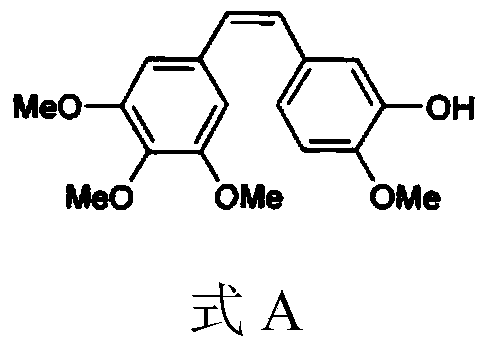

Combretastatin A4 derivative and preparation thereof

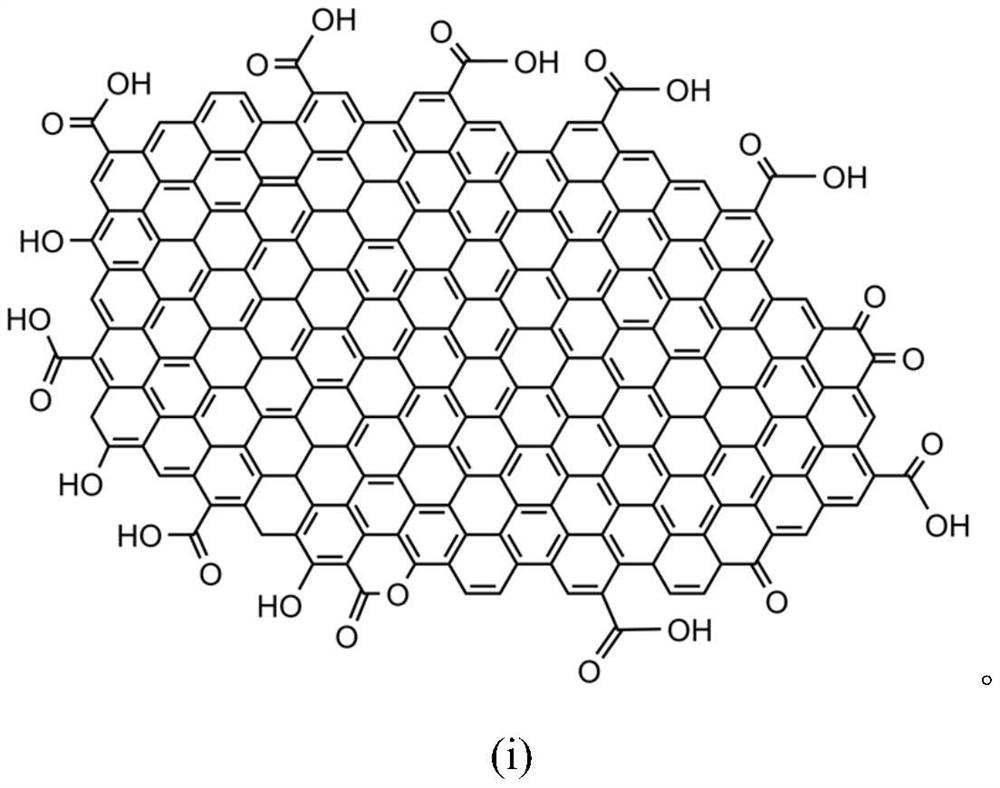

ActiveCN106580945ASolve the problem of poor fat solubilityImprove anti-tumor effectPowder deliveryOrganic compound preparationSide effectChloride

The invention belongs to the technical field of medicines, and in particular relates to a combretastatin A4 derivative preparation, wherein the derivative is obtained through the reaction between combretastatin A4 and stearyl chloride under the substitution reaction condition and under the condition that an acid-binding agent exits, and the structural formula of the derivative is as follows (shown in the description). The invention further provides a nanometer preparation of the derivative. The preparation has the advantages of improving the anti-tumor effect of medicines, enhancing the stability of the medicines, reducing the toxic and side effects of the medicines, etc.

Owner:SHANGHAI WEI ER BIOPHARM TECH CO LTD +3

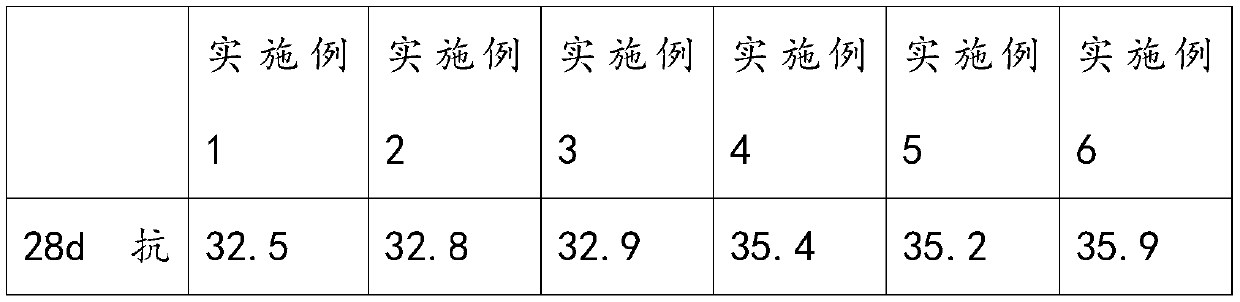

Pervious concrete

The invention relates to the field of building materials and provides pervious concrete to solve the problem of low strength of pervious concrete. The pervious concrete is prepared from components inparts by mass as follows: 80-100 parts of water, 30-40 parts of Portland cement, 50-60 parts of broken limestone, 30-35 parts of medium sand, 4-5 parts of stearoyl chloride, 5-6 parts of a sulfamate superplasticizer, 5-7 parts of waste textile fiber and 0.5-1 part of a coupling agent. By addition of the waste textile fiber, the waste textile fiber resource can be reasonably used, pollution of thewaste textile fiber to the environment can be reduced, meanwhile, the waste textile fiber can form a disorientation support system in the pervious concrete easily, so that orientation stress of the pervious concrete is dispersed, the number and size of pervious concrete cracks can be reduced, the anti-cracking and impervious capacity of the pervious concrete are enhanced, toughness of the perviousconcrete is improved, the tensile strength and compressive strength of the pervious concrete are further improved, and the service life of the pervious concrete is prolonged.

Owner:江苏泰林建设有限公司

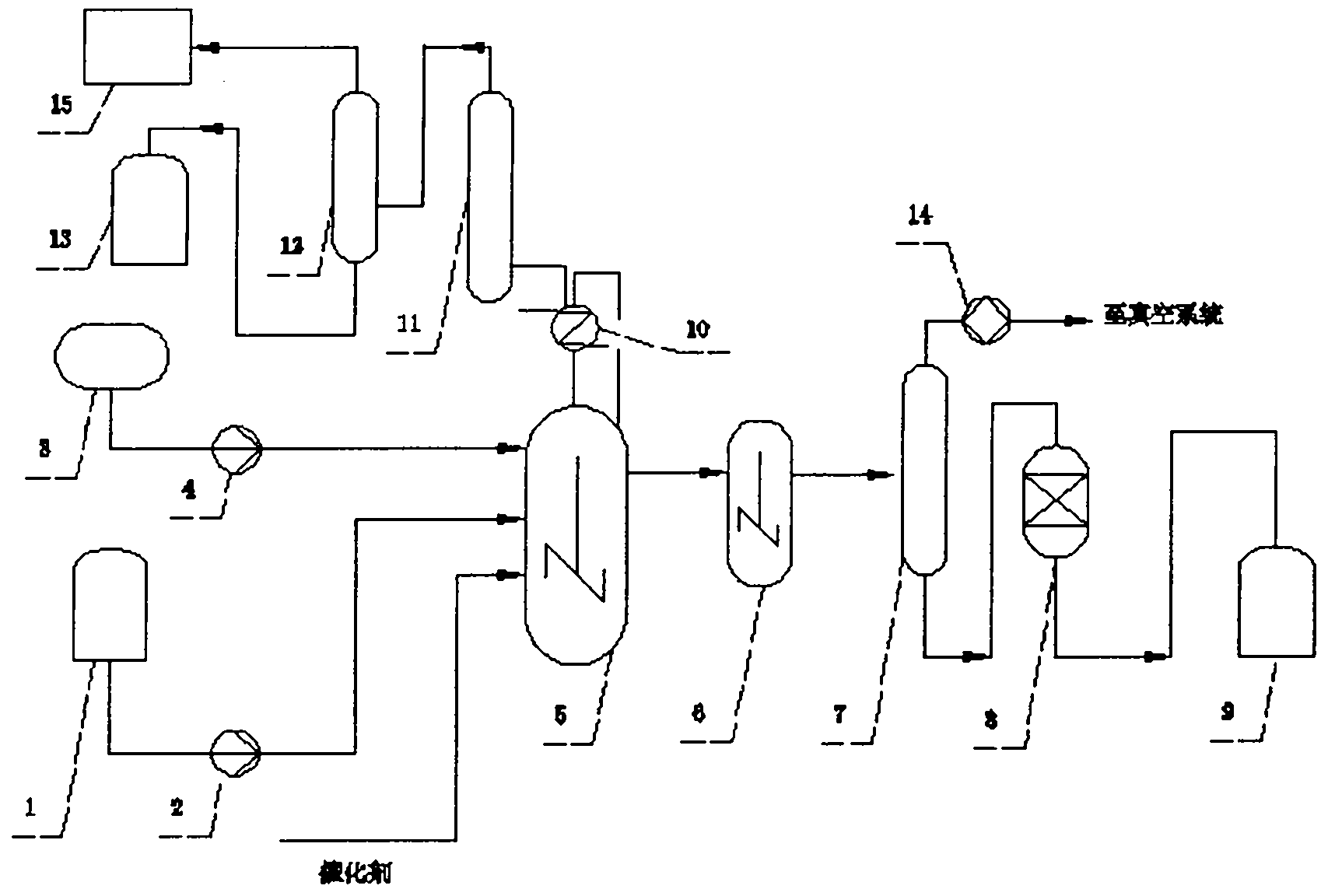

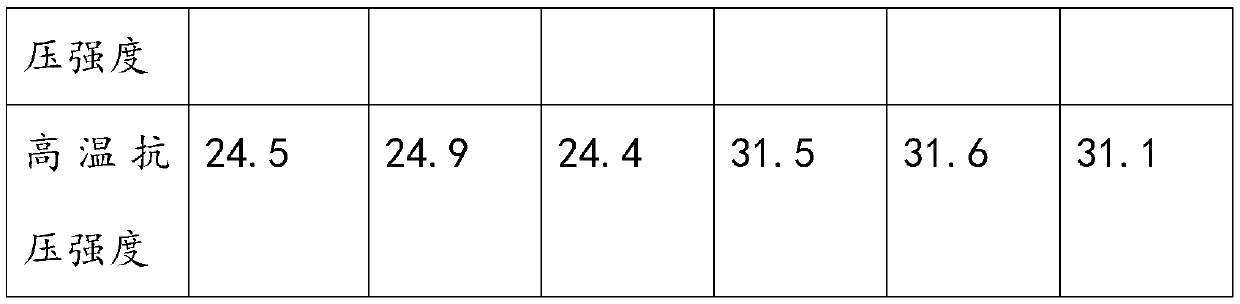

Method for continuously producing stearoyl acid chloride

InactiveCN104478698AImprove mass transfer effectQuick responseOrganic compound preparationCarboxylic compound preparationGas phaseTar

The invention relates to a method for continuously producing stearoyl acid chloride. The method comprises steps as follows: a, stearic acid and a catalyst are continuously and proportionally fed from a liquid phase feeding port in the top of a first bubble tower and sequentially enter a second bubble tower and a third bubble tower in a streaming manner; through forced circulation of a first tower bottom pump, a second tower bottom pump and a third tower bottom pump, a crude productstearoyl acid chloride is finally discharged out of a discharging port in the third tower bottom pump and then enters an acyl chloride refining procedure; b, fresh phosgeneenters a gas phase feeding portand continuously bubbles through the first bubble tower and the third bubble tower, exhaust of the first bubble tower enters the middle of the second bubble tower, exhaust of the third bubble tower enters the bottom of the second bubble tower, unreacted phosgene in exhaust of the first bubble tower and the third bubble tower continuously participates in reaction in the second bubble tower, and exhaust from the top of the second bubble tower enters a follow-up hydrochloric acid absorption procedure. According to the method and the device, the quality of stearoyl acid chloride produced through reaction is good, the crude productstearoyl acid chloride can be higher than 97.5%, the tar content of the crude product is low, and the follow-up treatment is easy.

Owner:甘肃银光聚银化工有限公司

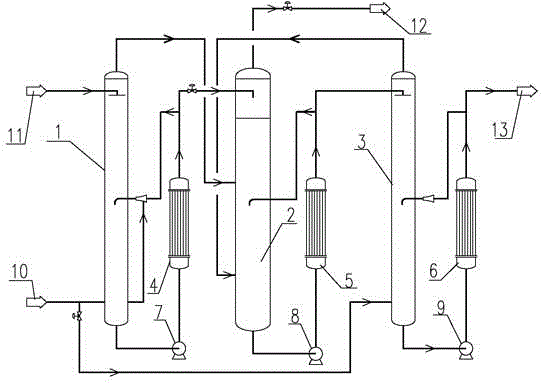

Preparation method for heatproof highly-basic anion exchange resin with great exchange capacity

ActiveCN105237666ALarge exchange capacityImprove thermal stabilityAnion exchangersNitrobenzeneOil phase

The invention discloses a preparation method for a heatproof highly-basic anion exchange resin with great exchange capacity. The preparation method comprises the following steps: preparing a first material from 3-methyl-3-hydroxymethyloxetane, trimethylol propane, sodium methylate, boron trifluoride ethyl ether, 2,3-glycidyltrimethylammonium chloride, N,N-dimethyl formamide and modified white carbon black; preparing a water phase and an oil phase; adding the oil phase into the water phase and continuing to add dichloroethane and sulfuryl chloride to prepare a second material; adding cetyl dimethyl tertiary amine into the second prefabricated material, carrying out mixing and adding 1,6-hexamethylene-bis(cyanoguanidine) and sodium ethoxide to prepare a third prefabricated material; and adding nitrobenzene, anhydrous AlCl3, stearoyl chloride, chlorododecane and chlorocycloparaffin to prepare the heatproof highly-basic anion exchange resin with great exchange capacity. The anion exchange resin prepared in the invention has good thermal stability and great exchange capacity.

Owner:ANHUI WANDONG CHEM

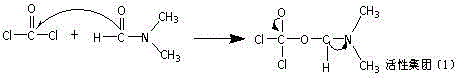

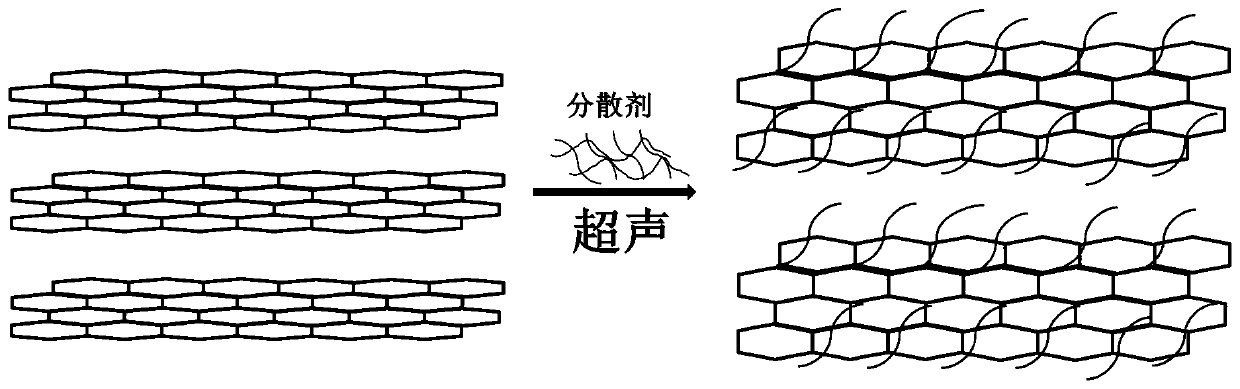

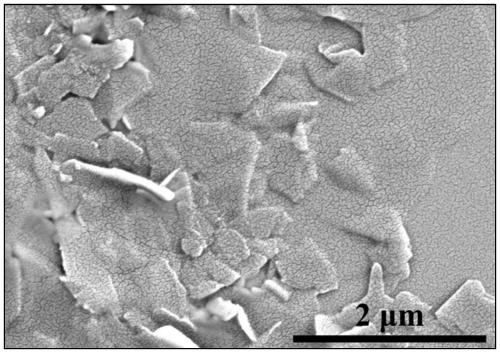

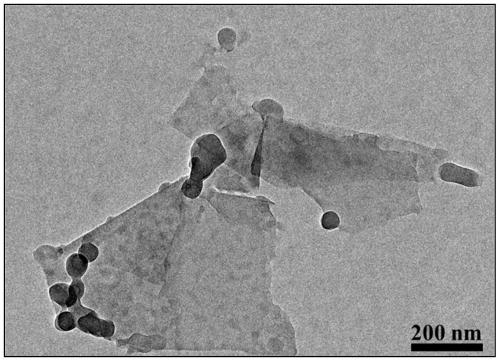

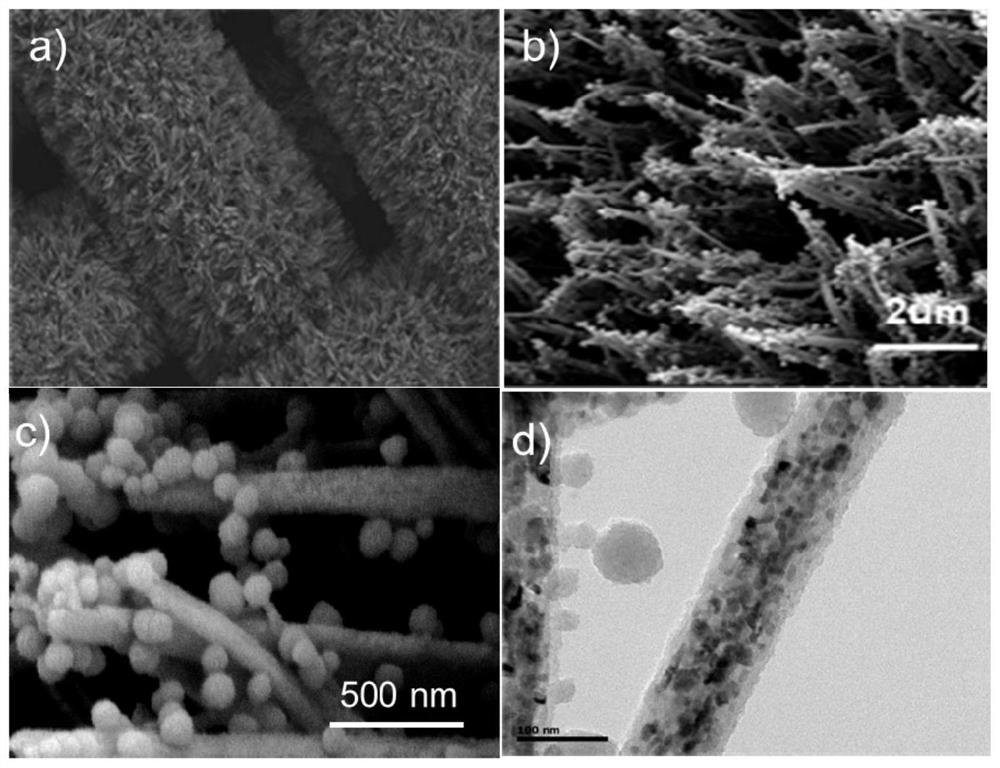

Graphene dispersing agent, preparation method thereof and preparation method of graphene

ActiveCN111170864ASimple preparation processMild reaction conditionsPreparation from carboxylic acid halidesTransportation and packagingFluid phaseAcyl group

The invention discloses a graphene dispersing agent, a preparation method thereof and a preparation method of graphene. 9-anthracenemethanoland stearoyl chloride are subjected to an affinity acyl substitution reaction to prepare the small-molecular graphene dispersing agent, the small-molecular graphene dispersing agent is used for liquid-phase stripping of graphite to prepare graphene, the efficiency is high, the environment is protected, the preparation process is simple, and the reaction conditions are mild and easy to control.

Owner:合肥艾克思维新材料科技有限公司

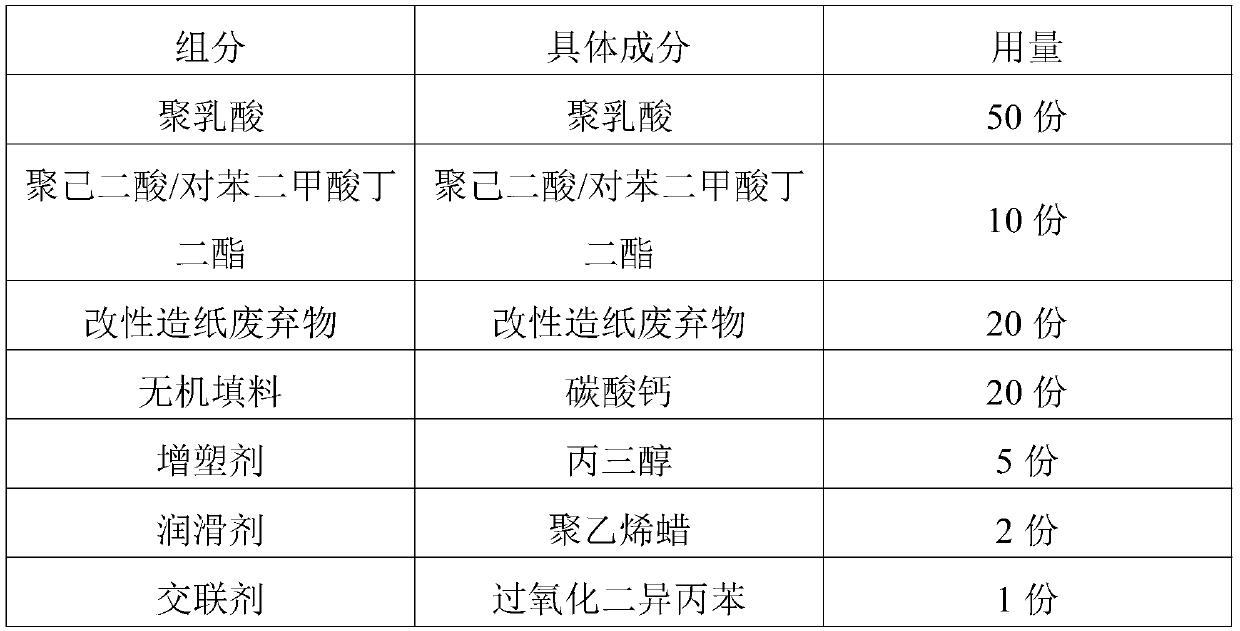

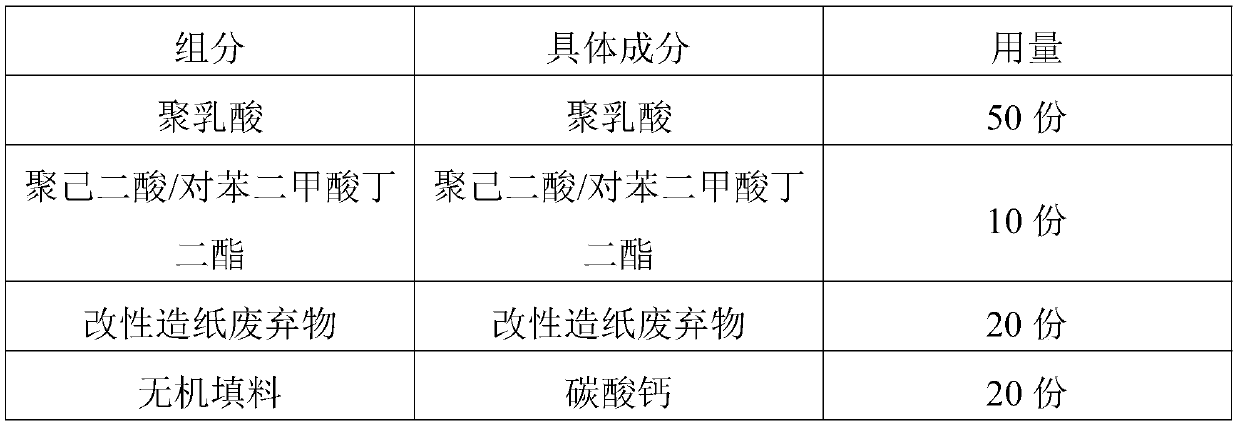

Raw material composition and master batch of biodegradable material and preparation method and application thereof

The invention discloses a raw material composition and master batch of a biodegradable material and a preparation method and application thereof. The raw material composition of the biodegradable material comprises the following components in parts by weight: 20-80 parts of polylactic acid, 1-40 parts of poly(butylene adipate-co-terephthalate), 1-40 parts of modified papermaking waste and 1-20 parts of an auxiliary agent, and the raw material composition of the modified papermaking waste comprises the following components in parts by weight: 100 parts of papermaking waste, 1-50 parts of a modifier and 0.1-5 parts of a phase transfer agent, wherein the modifier is one or more of stearoyl chloride, acetyl chloride, benzoyl chloride, oxalyl chloride, chloroacetyl chloride and trichloroacetylchloride. The biodegradable master batch and the material are easy to degrade in nature, the raw materials are renewable, and the cost is low. The prepared biodegradable material has good bending strength, flexural modulus and notch-free impact strength.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Method for preparing esterified porous starch by virtue of solvent method

InactiveCN106832014AIdeal degree of esterificationIdeal acidityFood ingredientsPorous starchChloride

The invention discloses a method for preparing esterified porous starch by virtue of a solvent method. The method disclosed by the invention comprises the following steps: mixing porous starch with triethylamine at normal temperature, adding anhydrous carbon tetrachloride and stearyl chloride, mixing and reacting, then separating out precipitates, washing and drying, so that the esterified porous starch is obtained. The method disclosed by the invention has the advantages that technological process is simple, production cost is low, yield of the prepared esterified porous starch is more than 93.08%, continuous large-scale production can be realized, and esterification degree of the obtained esterified porous starch can reach 1.7*10<6> peak area per gram and acidity can reach 10.47 DEG T.

Owner:南京福科帝生物科技有限公司

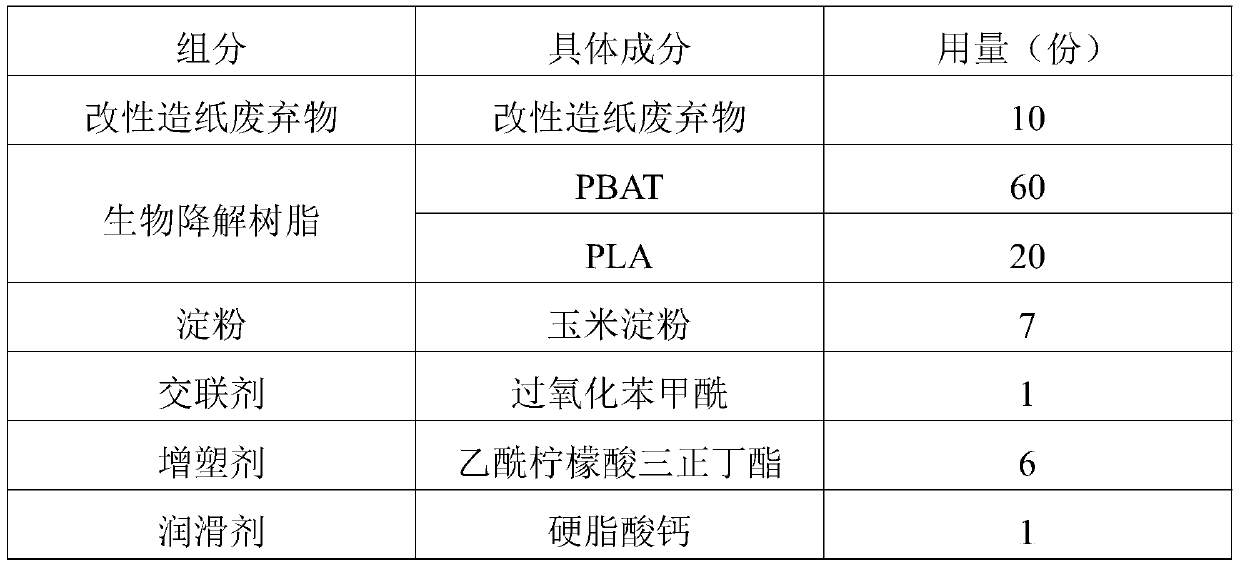

Biodegradable master batch, profile, raw material and preparation method of biodegradable master batch

InactiveCN111234037ANo pollutionRealize comprehensive utilizationStearoyl chlorideTrichloroacetyl chloride

The invention discloses a biodegradable master batch, a profile, a raw material and a preparation method of the biodegradable master batch. The raw material composition of the modified papermaking waste comprises the following components in parts by weight: 100 parts of papermaking waste, 1-50 parts of a modifier and 0.1-5 parts of a phase transfer agent, wherein the modifier is one or more of stearoyl chloride, acetyl chloride, benzoyl chloride, oxalyl chloride, chloroacetyl chloride and trichloroacetyl chloride. The modified papermaking waste is adopted, the compatibility of the modified papermaking waste and biodegradable resin can be effectively improved, and then the tensile strength and elongation at break of the biodegradable profile are improved, and the prepared biodegradable master batch and biodegradable profile can be completely degraded by microorganisms in the nature, so that waste utilization is realized and the cost is reduced.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

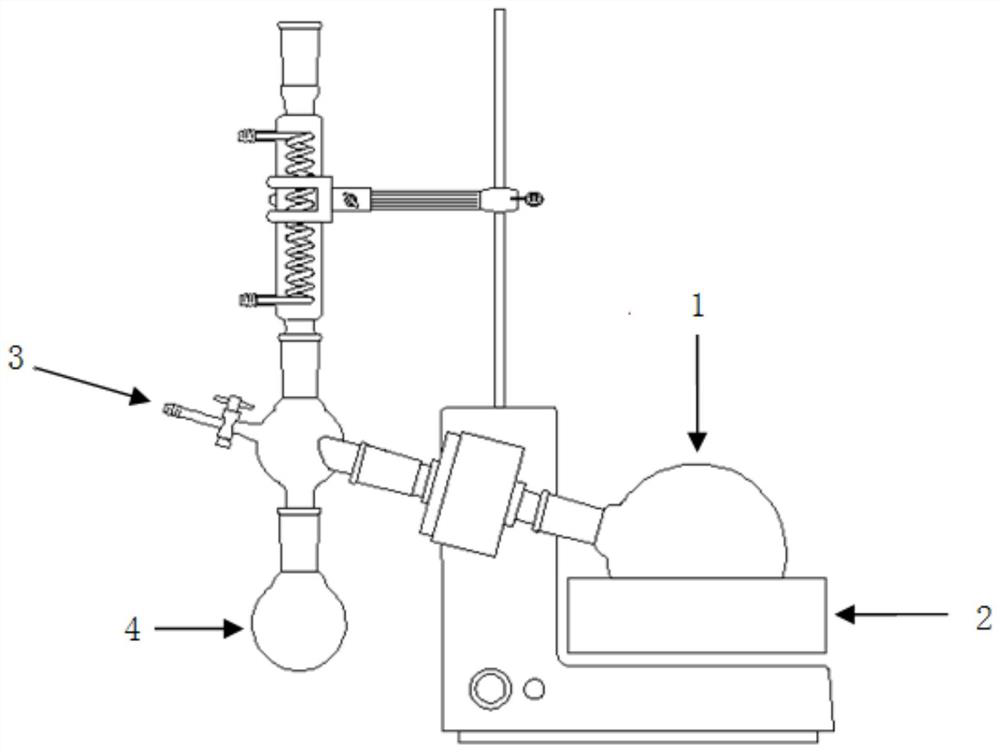

Preparation method of 4-tert-Butylbenzenesulfonamide-type concrete foaming agent

ActiveCN108002732AReduce surface tensionLow critical micelle concentrationSulfonic acid amide preparationEthylenediamineFoaming agent

The invention discloses a preparation method of a 4-tert-Butylbenzenesulfonamide-type concrete foaming agent. The method comprises the steps that 4-tert-Butylbenzenesulfonyl chloride, stearoyl chloride and hydroxyethyl ethylenediamine are put into a methylbenzene solvent, stirred, subjected to reflux reaction, cooled and subjected to rotary evaporation to remove the solvent, and after washing anddrying, a faint yellow powdery intermediate is obtained; then the intermediate is added to a sodium monochloroacetate aqueous solution for heating reaction, cooled and filtered, insoluble substances are removed, and the filtrate is an end product, namely the 4-tert-Butylbenzenesulfonamide-type concrete foaming agent. The prepared 4-tert-Butylbenzenesulfonamide-type concrete foaming agent can be used as the concrete foaming agent without separation and purification, and the preparation technology is simple, simple in process, easy to operate and high in practicability.

Owner:舒浪平 +2

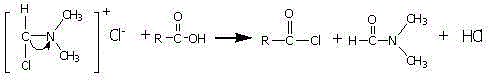

Novel solvent-free method for preparing AKD by taking tri-n-propylamine as raw material

According to the invention, triethylamine is replaced by tri-n-propylamine, and AKD is synthesized by carrying out a reaction on the tri-n-propylamine and stearoyl chloride through a solvent-free method, so that the viscosity of the reaction system can be reduced, and the purity and the yield of the AKD are effectively improved; and the feasibility of using tri-n-propylamine as a reactant tertiaryamine is proved. The invention relates to a solvent-free method for preparing alkyl ketene dimer AKD.

Owner:TIANJIN POLYTECHNIC UNIV

Polyvinyl chloride-based compatilizer and preparation method thereof

The invention relates to a polyvinyl chloride-based compatilizer, which is prepared from the following raw material ingredients including PTMEG sodium modified polyvinyl chloride, modified stearyl chloride, hexanedioic acid, hydroxyl silicone oil, polyoxyethylene polyoxypropylene segmented copolymers, dichlorophosphite pentaerythritol ester diisodecyl and magnesium stearate, wherein the PTMEG sodium modified polyvinyl chloride is prepared from polyvinyl chloride, PTMEG sodium, isopropanol and dimethylformamide through reaction; the PTMEG sodium is prepared from PTMEG, sodium phenate, ethyl alcohol and dimethylformamide through reaction. The polyvinyl chloride-based compatilizer has the effects of improving the material compatibility and the mechanical intensity.

Owner:王春望

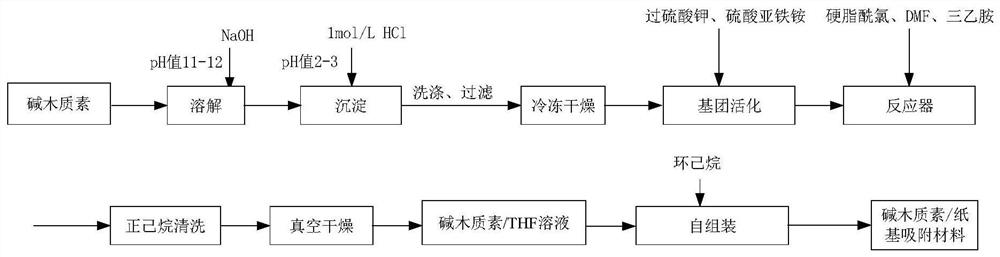

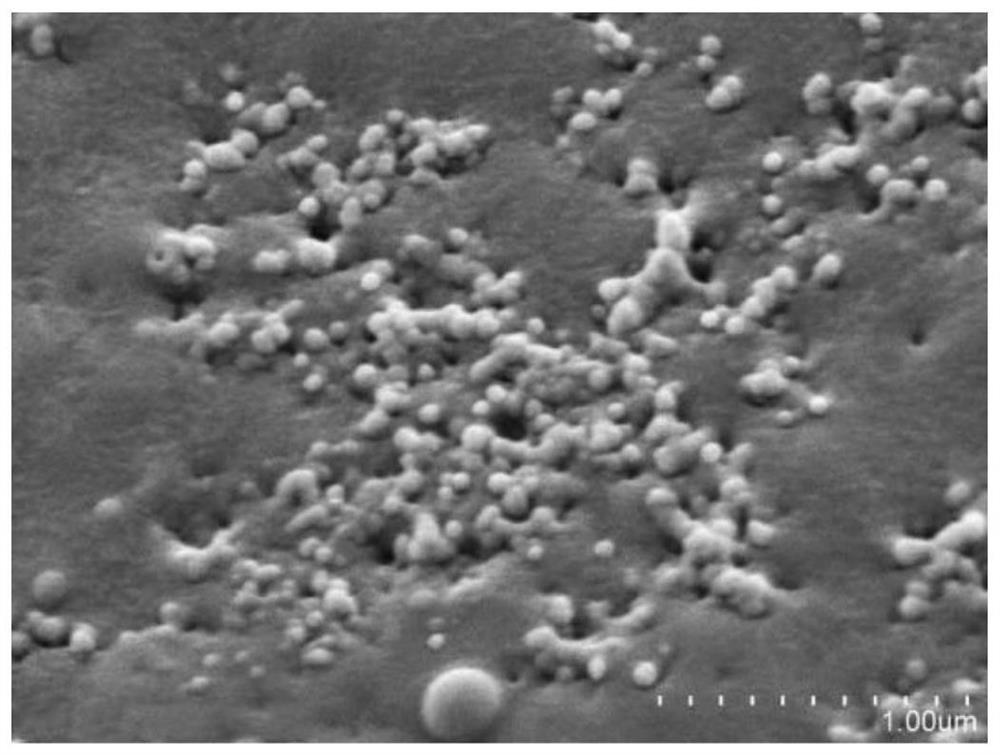

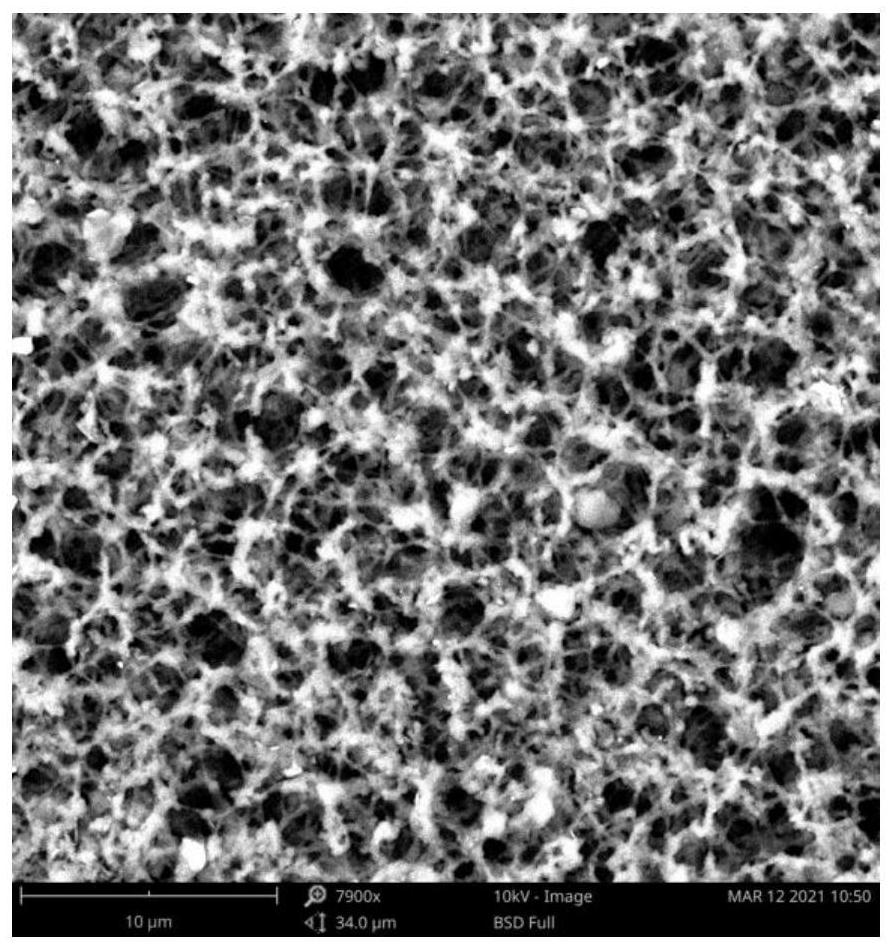

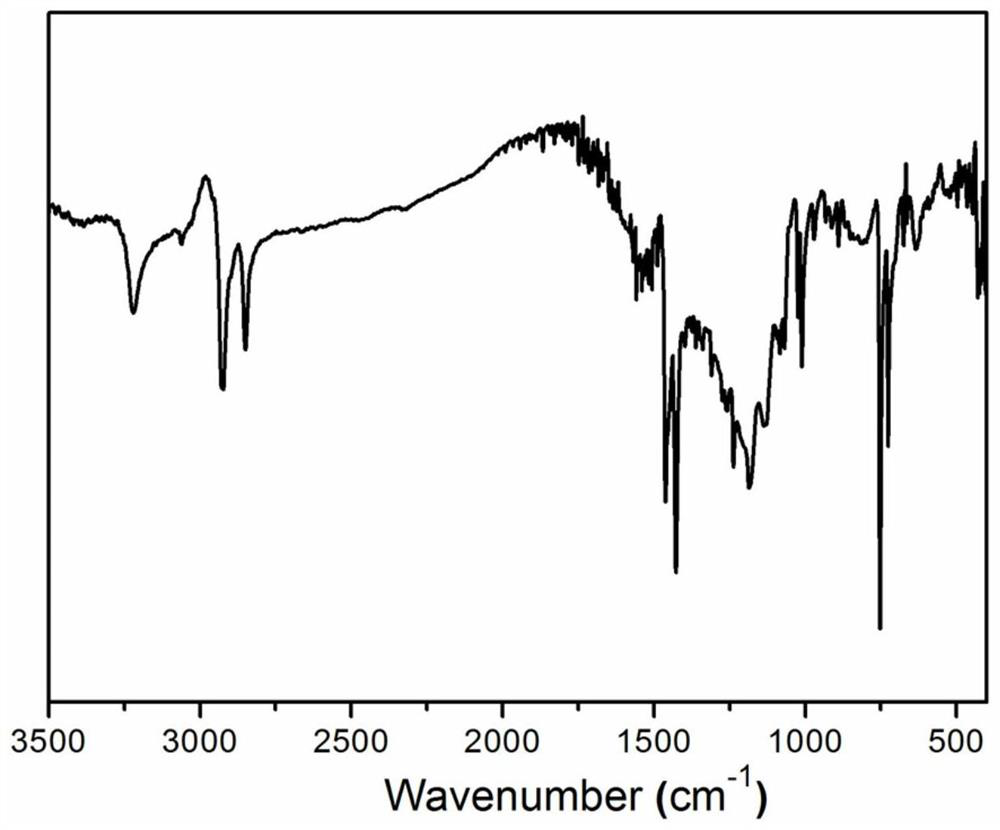

Alkali lignin micro-nanosphere/paper-based adsorption material, preparation method thereof and application of alkali lignin micro-nanosphere/paper-based adsorption material in dye wastewater treatment

ActiveCN113042008AReduce hydroxylReduced phenolic hydroxylOther chemical processesWater contaminantsStearoyl chlorideFilter paper

The invention discloses an alkali lignin micro-nanosphere / paper-based adsorption material, a preparation method thereof and application of the alkali lignin micro-nanosphere / paper-based adsorption material in dye wastewater treatment. The preparation method comprises the following steps that firstly, potassium persulfate and ammonium ferrous sulfate are used as initiators to improve the group activity of alkali lignin; then stearoyl chloride is used as an esterification reagent, N, N-dimethylformamide is used as a solvent, triethylamine is used as an acid applying agent and a catalyst, and the acetylation degree of the alkali lignin is controlled by controlling the ratio of stearoyl chloride to the alkali lignin; tetrahydrofuran is used as a solvent, cyclohexane is used as an anti-solvent, and the alkali lignin micro-nanospheres are prepared on filter paper in situ through a self-assembly method. The alkali lignin micro-nanospheres prepared by the method are micro-nano spherical reverse micelles with hydrophobic surfaces and hydrophilic interiors, can be well dispersed on water or a loading material, and are not easy to agglomerate. In addition, the adsorption material disclosed by the invention can be made into various shapes, is convenient to use and efficient in adsorption, can be recycled and reused, and is low in cost.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Stearoyl chloride phosgene recovery method

ActiveCN105289247AAvoid pollutionReduce wasteDispersed particle separationPhosgeneRecovery methodTemperature control

The invention provides a stearoyl chloride phosgene recovery method. The method comprises the following steps that firstly, tail gas generated stearoyle chloride production is introduced into a falling-film absorption tower; secondly, the temperature-increased gas is introduced into a cooling tower; thirdly, the cooled materials are introduced into a NaOH solution; thirdly, the discharged materials are transferred into a synthesizing kettle to be heated; fourthly, the materials of which the gas is exhausted are heated and filtered, and meanwhile the exhausted gas is continuously introduced into the NaOH solution; lastly, the gas is introduced into a filtering tank with drying agents, and then the gas is recovered. According to the stearoyl chloride phosgene recovery method, the production technology is adopted, and meanwhile temperature control is very important; the rest gas in the tail gas can be removed, and environmental pollution caused by direct emission of the tail gas is avoided; meanwhile, phosgene can be further recovered, the cost is lowered, the overall phosgene waste can be reduced, and the purity of the recovered recoverable phosgene is 69.9%-78.9%.

Owner:ANHUI GUANGXIN AGROCHEM

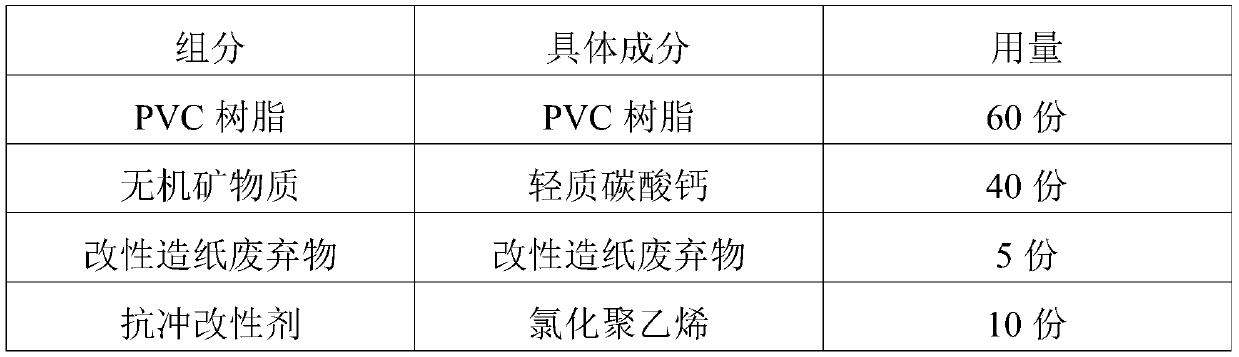

PVC micro-foaming profile, raw material, preparation method and application of the PVC micro-foaming profile

ActiveCN111269501AHigh tensile strengthImprove flexural strengthCovering/liningsAcetyl chlorideFoaming agent

The invention discloses a PVC micro-foaming profile, a raw material and a preparation method and application of the PVC micro-foaming profile. A raw material composition of the PVC micro-foaming profile comprises 1-20 parts of modified papermaking waste, 20-80 parts of PVC resin, 20-80 parts of inorganic minerals, 1-15 parts of an impact modifier, 1-5 parts of a plasticizer, 1-8 parts of a foamingagent, 2-20 parts of a polyvinyl chloride foaming regulator and 1-8 parts of a PVC stabilizer. The raw material composition of the modified papermaking waste comprises 100 parts of papermaking waste,1-50 parts of a modifier and 0.1-5 parts of a phase transfer agent, wherein the modifier is one or more of stearoyl chloride, acetyl chloride, benzoyl chloride, oxalyl chloride, chloroacetyl chlorideand trichloroacetyl chloride. According to the PVC micro-foaming profile, the modified papermaking waste is used as a raw material, so that the cost is reduced; the prepared PVC micro-foaming sectional material is smooth in surface, uniform in internal cell size and low in density, and the tensile strength and the bending strength are improved.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

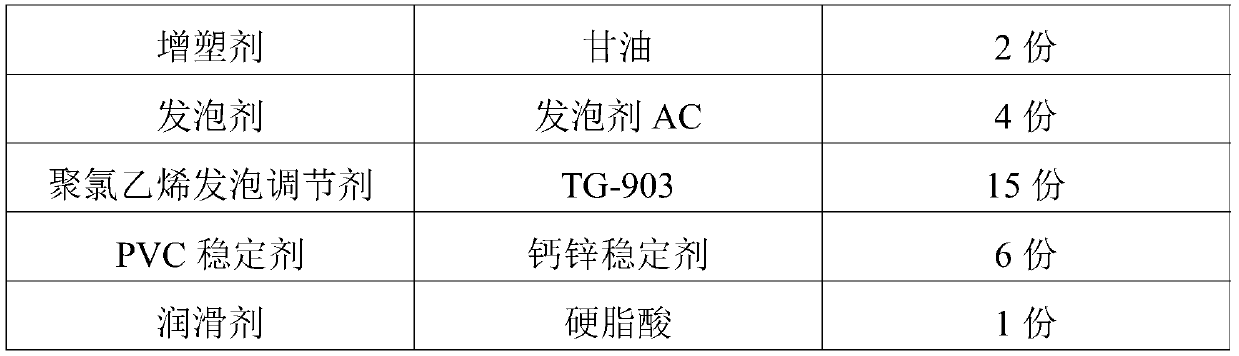

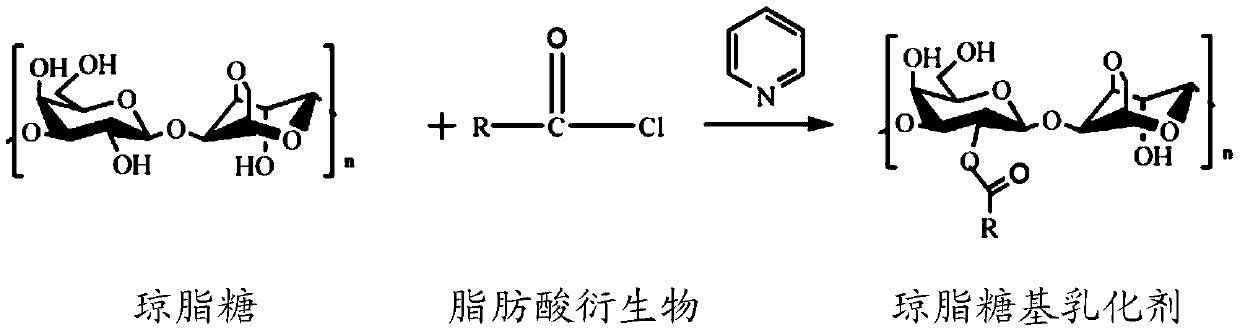

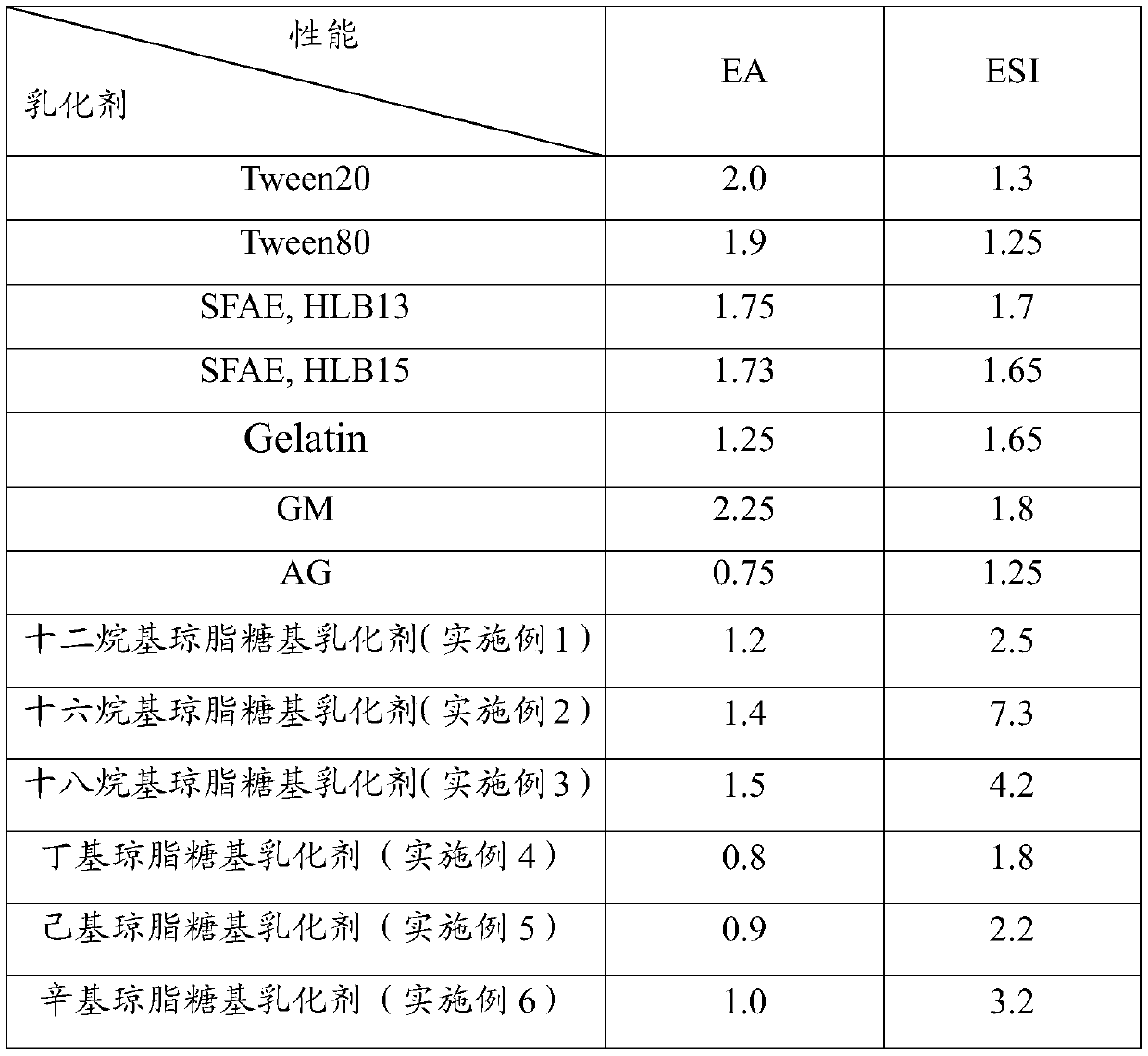

Agarose-based emulsifier as well as preparation method and application thereof

ActiveCN110479184ATemperature responsiveImprove stabilityTransportation and packagingMixingPalmitoyl chloridePropionyl chloride

The invention discloses an agarose-based emulsifier. Raw materials comprise agarose and a fatty acid derivative, wherein the molar ratio of the agarose to the fatty acid derivative is (1:2)-(1:4), themolar weight of the agarose is metered by disaccharide units, and the fatty acid derivative is acetyl chloride, propionyl chloride, butyryl chloride, valeryl chloride, hexanoyl chloride, capryloyl chloride, decanoyl chloride, lauroyl chloride, myristoyl chloride, palmitoyl chloride or stearoyl chloride. The invention further discloses a preparation method of the agarose-based emulsifier, esterification modification of the agarose is realized by adopting a solvent method, the process is simple, the efficiency is high, and industrial production is easy to realize. The agarose-based emulsifier has a potential application prospect in the industries of medicines, cosmetics and foods.

Owner:HUAQIAO UNIVERSITY +1

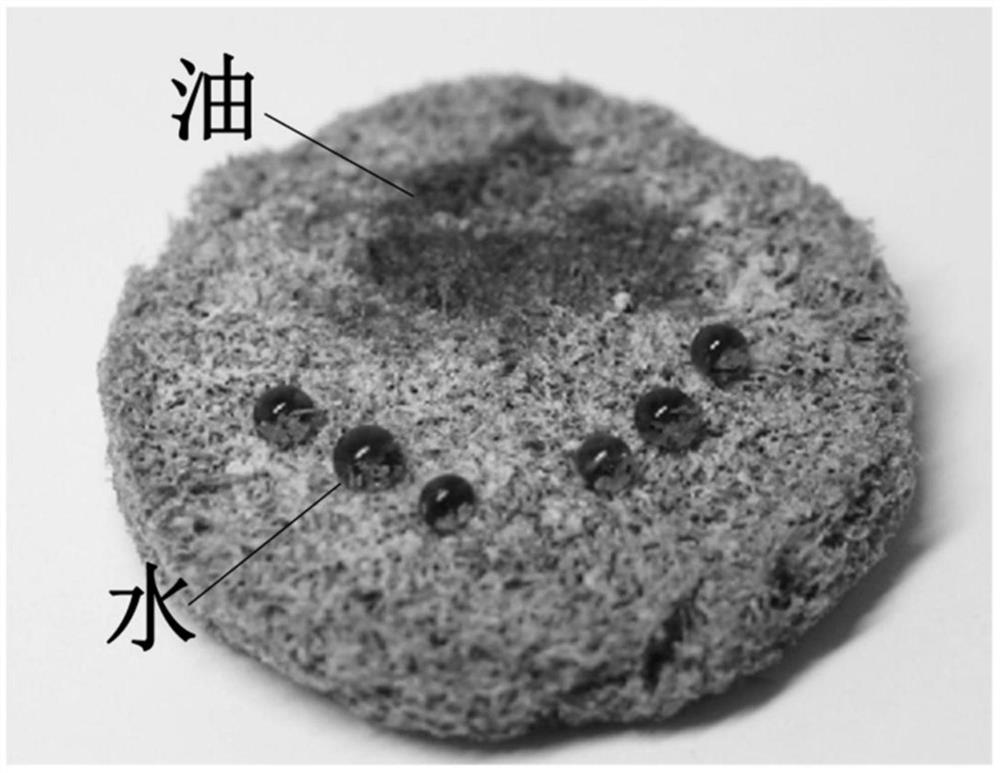

Preparation method of super-hydrophobic-super-oleophylic straw felt for oil-water separation

ActiveCN112057899AEfficient separationExcellent superhydrophobic propertiesNon-miscible liquid separationIndustrial effluentAqueous sodium hydroxide

The invention discloses a preparation method of a super-hydrophobic super-oleophylic straw felt for oil-water separation. The method mainly comprises the following steps: 1, cutting straw stalks to aspecific length, soaking in a sodium hydroxide aqueous solution for treatment, fishing out, and washing with water to neutrality; 2, pressing the mixture into a mold with a specific shape, drying andmolding; 3, taking stearoyl chloride as a solute, taking 1,4- anhydrous dioxane as a solvent, mixing to form a low-surface-energy solution, soaking the formed straw into the solution for low-surface-energy treatment, taking out, and drying; and 4, putting the straw subjected to low surface energy treatment into an elastic porous cotton packaging bag which is consistent with the straw in shape to form the super-hydrophobic super-oleophylic straw felt. The product is low in cost, high in strength and not prone to being scattered by stormy waves, and has good application prospects in the fields of marine spilled oil cleaning, industrial wastewater treatment and the like.

Owner:DALIAN UNIV OF TECH

A kind of preparation method and application of composite rubber filler

ActiveCN111718516BImprove responseGood dispersionPigment treatment with non-polymer organic compoundsPolymer scienceThiazole

The invention provides a preparation method of a composite rubber filler, comprising the following steps: (1) carrying out acid chlorination treatment on acid carbon black and stearic acid to obtain a mixture of acid chloride modified carbon black and stearyl chloride; (2) Add N-cyclohexyl-2-benzothiazole sulfenamide to the mixture obtained in step (1), heat to 60-80°C, react for 5-8h under vacuum conditions, heat up after the reaction to remove impurities, and obtain a composite rubber filler. The invention also provides a rubber which uses the composite rubber filler as a raw material. The present invention starts with the active carboxyl group on the acidic carbon black, and proposes a composite filler that adopts CBS amination modification to treat carbon black and stearic acid. The filler is used in in-situ grafted rubber. By adopting the conventional one-stage mixing process at room temperature, a compound with better dispersion of carbon black can be obtained, and the rebound and compression permanent deformation properties of the compound are significantly improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Stearoyl chloride phosgene synthesis method

InactiveCN105367406AIncrease contact areaReduce wasteOrganic compound preparationCarboxylic compound preparationSynthesis methodsFirst-order reaction

The invention provides a stearoyl chloride phosgene synthesis method. The method comprises the steps of 1, heating stearic acid; 2, heating the catalyst DMF; 3, introducing phosgene into a first-order reaction chamber continuously; 4, spraying heated stearic acid downwards through a spraying device, and spraying the heated catalyst DMF downwards through the spraying device at the same time; 5, introducing gas which does not react completely into a second-order reaction chamber; 6, introducing gas which does not react completely into a third-order reaction chamber; 7, introducing gas into a tail gas processing device; 8, rectifying materials obtained after reaction is conducted in the first-order reaction chamber, the second-order reaction chamber and the third-order reaction chamber, so that a finished product is obtained. By the adoption of the production technology, the contact area of reactants can be increased, reaction time can be shortened, increase of by-products can be avoided, and therefore reaction efficiency is improved, cost is reduced, and phosgene waste is reduced.

Owner:ANHUI GUANGXIN AGROCHEM

A kind of waste material filtering method of stearoyl chloride

ActiveCN105367408BIncrease contact areaReduce wasteOrganic compound preparationCarboxylic compound preparationFiltrationTar

Owner:ANHUI GUANGXIN AGROCHEM

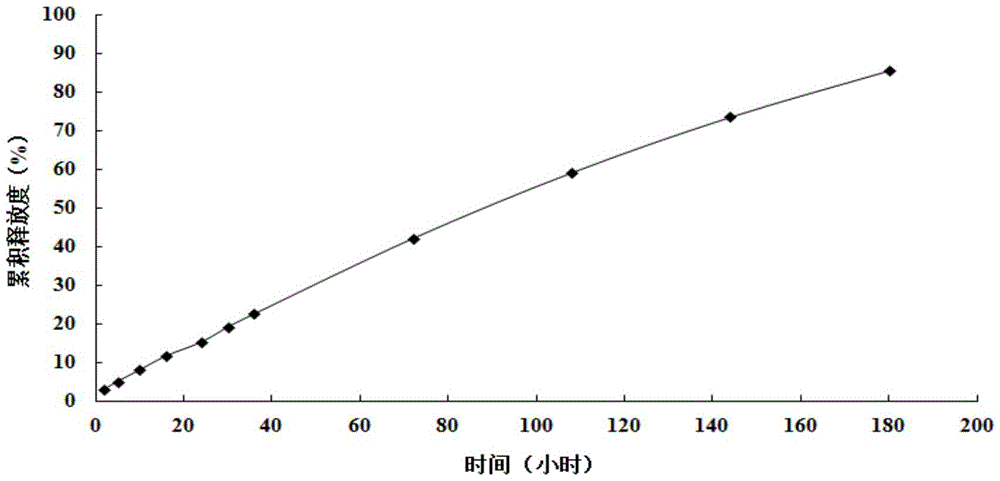

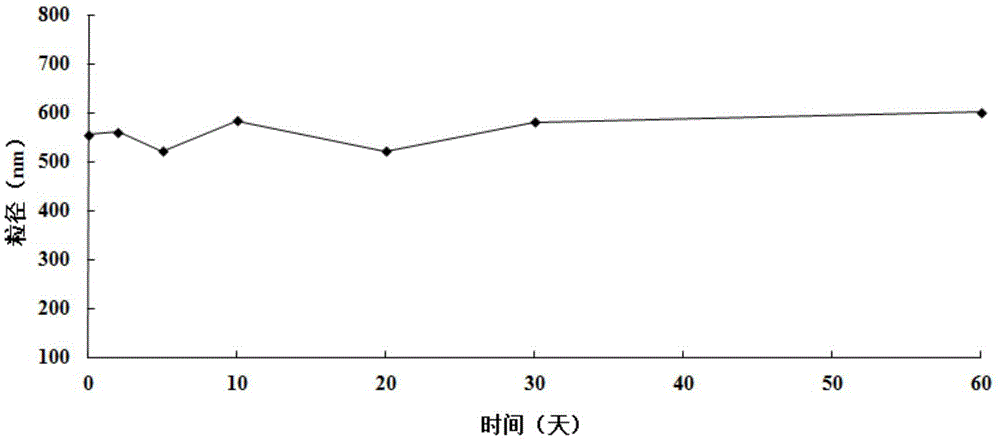

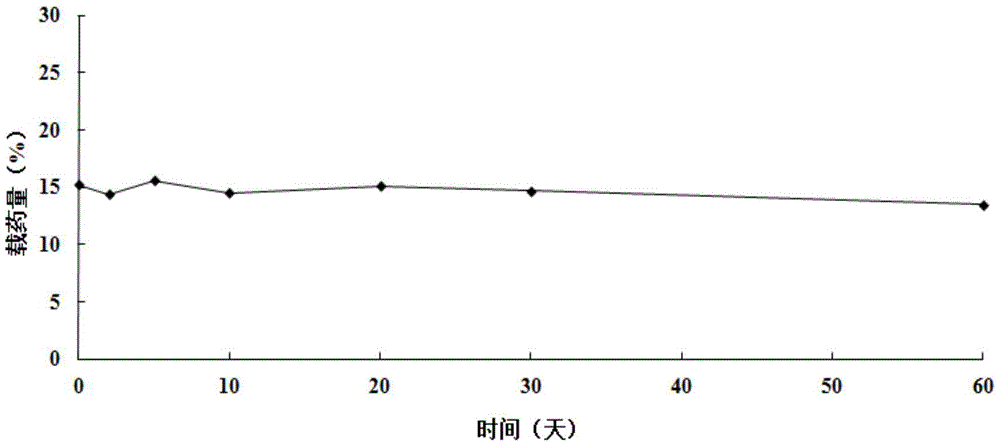

Supermolecule hydrogel system loaded with 10-hydroxycamptochecine and method for preparing supermolecule hydrogel system

ActiveCN105616340AHigh drug loadingConstant release rateOrganic active ingredientsAerosol deliveryPolyvinyl alcoholCyclodextrin

The invention provides a supermolecule hydrogel system loaded with 10-hydroxycamptochecine and a method for preparing the supermolecule hydrogel system. The supermolecule hydrogel system comprises fatty acid esterified grafted polyvinyl alcohol, alpha-cyclodextrin and the 10-hydroxycamptochecine. At least two types of fatty acid chloride and polyvinyl alcohol are simultaneously esterified to obtain the fatty acid esterified grafted polyvinyl alcohol, the fatty acid chloride selectively includes at least two types of hexanoyl chloride, octanoyl chloride, lauroyl chloride, myristoyl chloride, oleoyl chloride and stearyl chloride, and every two carbon chains of the selected fatty acid chloride are different from each other by six carbon atoms at least. The supermolecule hydrogel system and the method have the advantages that the 10-hydroxycamptochecine can be released from the supermolecule hydrogel system at constant speeds, accordingly, hydrogel is high in safety, the method is simple, and the supermolecule hydrogel system is high in drug-loading capacity and good in stability.

Owner:ZHEJIANG UNIV OF TECH

A kind of method for continuously producing stearyl chloride

InactiveCN104478698BImprove mass transfer effectQuick responseOrganic compound preparationCarboxylic compound preparationGas phaseTar

The invention relates to a method for continuously producing stearoyl acid chloride. The method comprises steps as follows: a, stearic acid and a catalyst are continuously and proportionally fed from a liquid phase feeding port in the top of a first bubble tower and sequentially enter a second bubble tower and a third bubble tower in a streaming manner; through forced circulation of a first tower bottom pump, a second tower bottom pump and a third tower bottom pump, a crude productstearoyl acid chloride is finally discharged out of a discharging port in the third tower bottom pump and then enters an acyl chloride refining procedure; b, fresh phosgeneenters a gas phase feeding portand continuously bubbles through the first bubble tower and the third bubble tower, exhaust of the first bubble tower enters the middle of the second bubble tower, exhaust of the third bubble tower enters the bottom of the second bubble tower, unreacted phosgene in exhaust of the first bubble tower and the third bubble tower continuously participates in reaction in the second bubble tower, and exhaust from the top of the second bubble tower enters a follow-up hydrochloric acid absorption procedure. According to the method and the device, the quality of stearoyl acid chloride produced through reaction is good, the crude productstearoyl acid chloride can be higher than 97.5%, the tar content of the crude product is low, and the follow-up treatment is easy.

Owner:甘肃银光聚银化工有限公司

Oil-water separating membrane material as well as preparation method and application thereof

ActiveCN113975979AImprove hydrophobicity and lipophilicityImprove corrosion resistanceSemi-permeable membranesMembranesNanowirePolypyrrole

The invention belongs to the technical field of nanomaterials, and particularly relates to an oil-water separating membrane material and a preparation method and application thereof. The oil-water separating membrane material is characterized in that an initiation system composed of copper oxide nanowires and ethyl alcohol is used for initiating pyrrole monomers to be subjected to in-situ oxidation-reduction polymerization on the surfaces of the copper oxide nanowires, a compact polypyrrole coating layer is formed, and a CuO (Cu2O)@ppy material of a core-shell structure is constructed; and a super-hydrophobic and super-oleophylic oil-water separating membrane material is obtained by modifying the surface of the material with super-hydrophobic stearoyl chloride, has excellent photo-thermal conversion performance, extremely high corrosion resistance and long service life, can be repeatedly used, and can be used for realizing efficient purification and recovery of crude oi. The crisis of energy shortage is relieved, meanwhile, sewage recycling is completed, and the environmental problem is relieved.

Owner:深圳中拓天达环境工程有限公司

A kind of waste treatment method of stearoyl chloride

ActiveCN105294420BIncrease contact areaReduce wasteOrganic compound preparationCarboxylic compound preparationActivated carbonFiltration

The invention provides a stearoyl chloride waste material treating method. The method comprises the following steps that firstly, coarse stearoyl chloride is heated; secondly, an activated carbon adsorbent is added in the coarse stearoyl chloride; thirdly, primary cooling is performed on liquid obtained after activated carbon adsorption; fourthly, high-temperature evaporation is performed on residues obtained through filtration; fifthly, gas generated through evaporation is collected, and then secondary cooling is performed on the gas; sixthly, the materials processed through secondary cooling are sent into a dryer and a sprayer to be dried; lastly, the dried materials are introduced into a concentrator to be concentrated, collecting is performed, and then further treating is performed. According to the stearoyl chloride waste material treating method, by adopting the production technology, tar substances in the coarse stearoyl chloride can be thoroughly separated; meanwhile, a side reaction can be prevented from being further generated to influence the purity of stearoyl chloride when the coarse stearoyl chloride is separated again at the certain temperature and time under the certain pressure.

Owner:ANHUI GUANGXIN AGROCHEM

The decolorization method of crude stearoyl chloride

InactiveCN104592003BReduce wasteEasy to handleOrganic compound preparationCarboxylic compound preparationActivated carbonPhysical chemistry

The invention relates to a decolorization method of stearoyl chloride, which is characterized in that the colored thick stearoyl chloride is preheated to 80-200°C in a preheater, and then enters an evaporator, under an absolute pressure of 5Pa to 50KPa, Circulating evaporation between 120 and 250°C, the heavy components at the bottom of the evaporator are pumped into the tar concentrator through a circulating pump for further concentration and evaporation, and the tar with heavy components is discharged from the bottom for treatment, and the gas phase at the top of the evaporator and tar concentrator passes through the condenser And subcooler cooling to obtain colorless pure stearyl chloride product. The invention realizes continuous decolorization of crude stearyl chloride containing heavy components, has high production capacity, and low treatment cost. Compared with the activated carbon adsorption decolorization process, the product of the invention has low chroma, and is suitable for removing high-boiling-point tar in heat-sensitive substances.

Owner:甘肃银光聚银化工有限公司

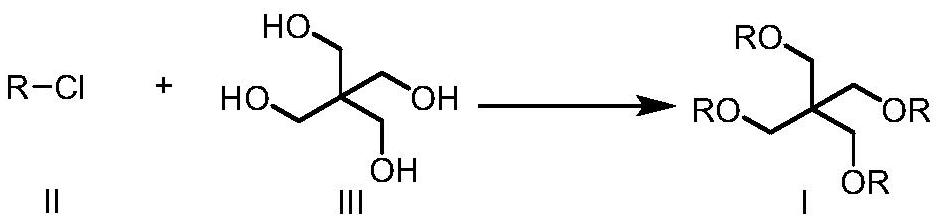

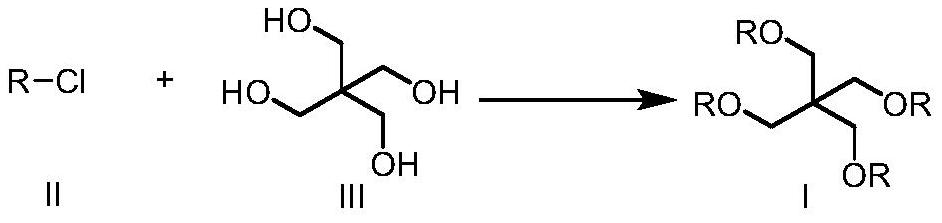

Preparation method of pentaerythritol tetraisostearate

PendingCN111848397AMild reaction conditionsLow reaction temperaturePreparation from carboxylic acid halidesIsostearic acidPtru catalyst

The invention provides a preparation method of pentaerythritol tetraisostearate. The preparation method specifically comprises the following steps: S1, taking pentaerythritol and isostearoyl chlorideaccording to a molar ratio of 1: (3.8-4.8), and putting the pentaerythritol and the isostearoyl chloride into a reaction kettle; and S2, carrying out a reaction for 0.5-12 h at a reaction temperatureof 80-150 DEG C under a vacuum pressure of-0.1 MPa to-0.05 MPa so as to obtain the pentaerythritol tetraisostearate product. The method does not need a catalyst; the reaction conditions are mild, thereaction temperature is greatly reduced, and a conventional enamel reaction kettle can be used; reaction time is short, and energy consumption is low; the product is light in color and high in quality; the method is simple in post-reaction treatment and suitable for industrialization.

Owner:NANJING NUTRABUILDING BIO TECH CO LTD

A kind of combretastatin A4 derivative and preparation thereof

ActiveCN106580945BSolve the problem of poor fat solubilityImprove anti-tumor effectPowder deliveryOrganic compound preparationSide effectPharmaceutical drug

The present invention belongs to the field of medical technology, and in particular relates to a preparation of a combretastatin A4 derivative, said derivative being obtained by reacting the combretastatin A4 with stearyl chloride in the presence of substitution reaction conditions and an acid-binding agent, and the structural formula whereof is shown as (I). Also provided in the present invention is a nano-preparation of the derivative. The preparation has many advantages, such as improving the anti-tumor effect of the medicine, increasing the stability of the medicine and reducing the toxicity and side effects of the medicine, etc.

Owner:SHANGHAI WEI ER BIOPHARM TECH CO LTD +3

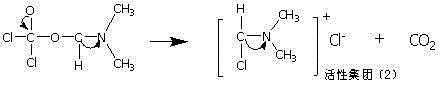

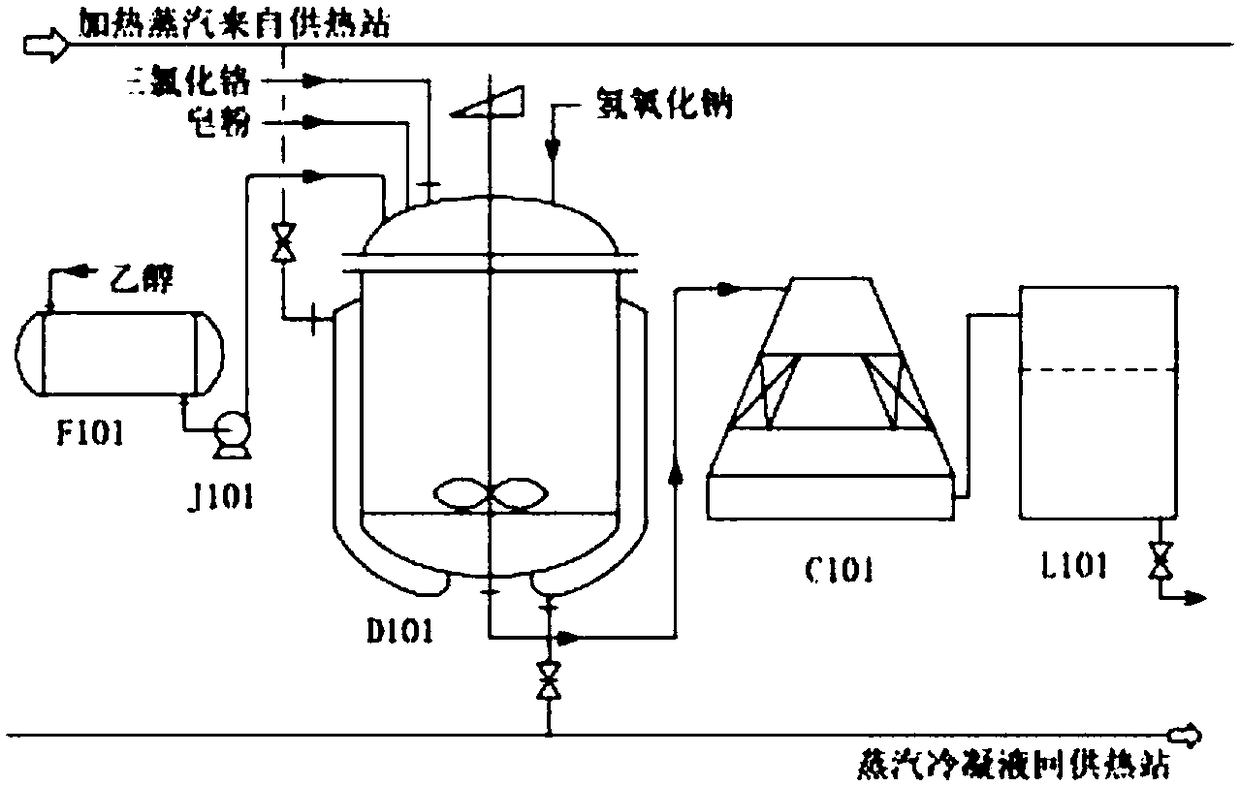

Production device for water-proofing agent stearoyl chromium chloride

InactiveCN108239877AReduction of intermediate links in the reactionLow reaction temperatureFibre treatmentChlorideProcess engineering

The invention relates to a production device for a water-proofing agent stearoyl chromium chloride. The production device mainly comprises a storage tank (F101), a pump (J101), a reaction kettle (D101), a cooler (C101) and a filter (L101), wherein the pump (J101) is respectively connected with the storage tank (F101) and the reaction kettle (D101), the cooler (C101) is respectively connected withthe reaction kettle (D101) and the filter (L101), and nominal volume of the storage tank (F101) is 4.2-4.6m<3>.

Owner:CHENGDU PA LUO AO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com