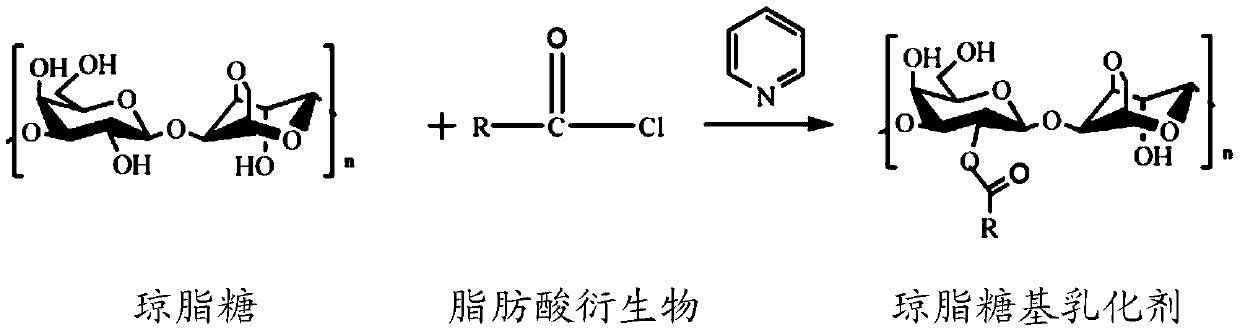

Agarose-based emulsifier as well as preparation method and application thereof

An agarose-based and emulsifier technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve problems such as lack of amphiphilicity, inability to effectively reduce surface tension and interfacial tension, and limitations. Achieve the effects of reducing flocculation and coalescence, enhancing stability and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

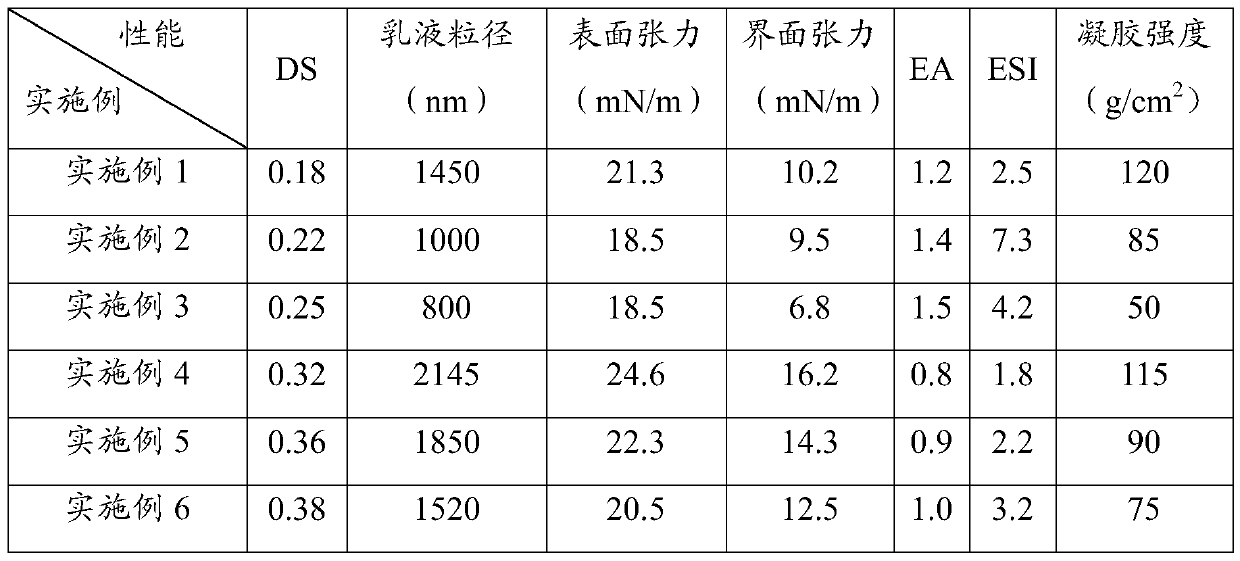

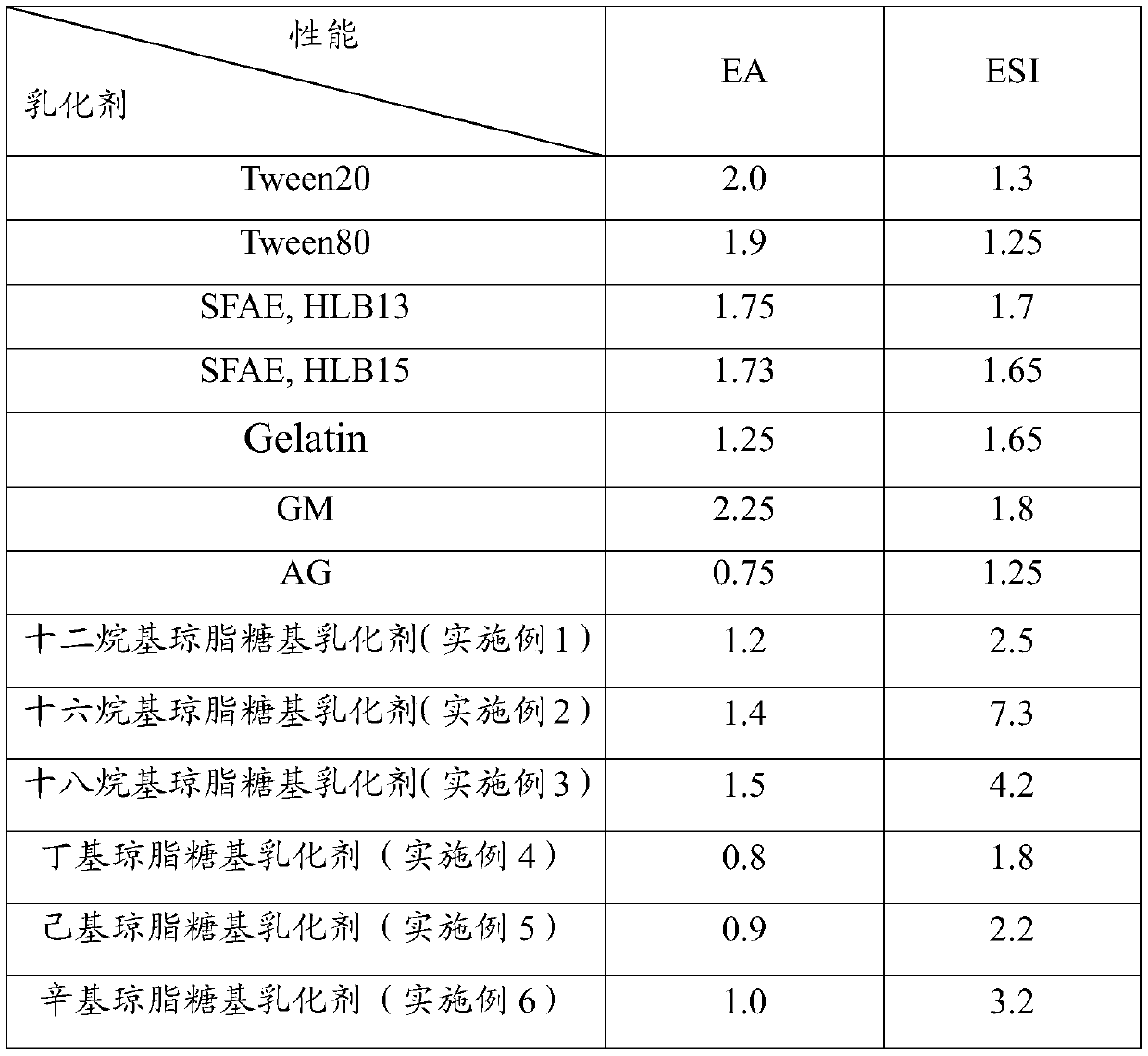

Embodiment 1

[0030] A preparation method of agarose-based emulsifier, comprising the following steps:

[0031] Step 1. Weigh 20g of agarose (0.06M, calculated as disaccharide units) and disperse it in a pyridine solvent to form an agarose suspension with a mass concentration of 20%;

[0032] Step 2. Add 21.7g (0.12M) of lauroyl chloride dropwise to the agarose suspension under magnetic stirring at a stirring speed of 350rpm, and react at 80°C for 1 hour;

[0033] Step 3. After the reaction is over, add 100mL of ethanol to terminate the reaction, let it stand for 30 minutes and filter, then wash and filter with ethanol and deionized water in turn;

[0034] Step 4. Finally, 100 mL of ethanol with a volume concentration of 50% is mixed with the product obtained by filtration, the residual organic solvent is removed after rotary evaporation, and the dodecyl agarose-based emulsifier is obtained after drying and crushing.

Embodiment 2

[0036] A preparation method of agarose-based emulsifier, comprising the following steps:

[0037] Step 1. Weigh 20g of agarose (0.06M, calculated as disaccharide units) and disperse it in a pyridine solvent to form an agarose suspension with a mass concentration of 20%;

[0038] Step 2. Add 28.4g (0.12M) palmitoyl chloride dropwise to the agarose suspension under magnetic stirring at a stirring speed of 350rpm, and react at 80°C for 1 hour;

[0039] Step 3. After the reaction is over, add 100mL of ethanol to terminate the reaction, let it stand for 30 minutes and filter, then wash and filter with ethanol and deionized water in turn;

[0040] Step 4. Finally, 100 mL of ethanol with a volume concentration of 50% is mixed with the product obtained by filtration, the residual organic solvent is removed after rotary evaporation, and the hexadecyl agarose-based emulsifier is obtained after drying and crushing.

Embodiment 3

[0042] A preparation method of agarose-based emulsifier, comprising the following steps:

[0043] Step 1. Weigh 20g of agarose (0.06M, calculated as disaccharide units) and disperse it in a pyridine solvent to form an agarose suspension with a mass concentration of 20%;

[0044] Step 2. Add 31.9g (0.12M) stearoyl chloride dropwise to the agarose suspension under magnetic stirring at a stirring speed of 350rpm, and react at 80°C for 1 hour;

[0045]Step 3. After the reaction is over, add 100mL of ethanol to terminate the reaction, let it stand for 30 minutes and filter, then wash and filter with ethanol and deionized water in turn;

[0046] Step 4. Finally, 100 mL of ethanol with a volume concentration of 50% was mixed with the product obtained by filtration, and the residual organic solvent was removed after rotary evaporation, and the octadecyl agarose-based emulsifier was obtained after drying and crushing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com