Decoloring method of crude stearyl chloride

A technology of stearoyl chloride and acid chloride, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of difficult to achieve rectification decolorization and high tar generation rate, and achieve high productivity and improved product quality , the effect of low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

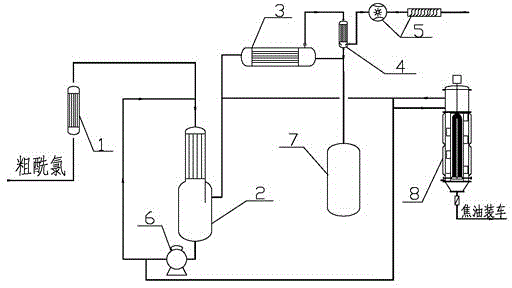

[0023] Example 1, see figure 1 :

[0024] The crude stearyl chloride generated by the photochemical reaction is continuously pumped into the preheater 1 at a flow rate of 120kg / h, heated to 120°C, and then enters the acid chloride evaporator 2, where the acyl chloride is circulated in the acid chloride evaporator 2, and the material at the bottom of the evaporator is recycled The circulation pump 6 is pumped into the concentrator 8 for tar concentration. The acid chloride evaporator is composed of two-stage falling film evaporators in series, the pressure is controlled at an absolute pressure of 600Pa, the temperature of the first-stage falling-film evaporator is controlled at 185°C, and the temperature of the second-stage falling-film evaporator is controlled at 196°C. The concentrator 8 is a wiped film evaporator, the pressure is controlled at an absolute pressure of 400 Pa, and the temperature is controlled at 210°C. Continuous operation obtained 472kg of stearyl chloride...

Embodiment 2

[0025] Example 2, see figure 1 :

[0026] The crude stearyl chloride generated by the photochemical reaction is continuously pumped into the preheater 1 at a flow rate of 150kg / h, heated to 180°C, and then enters the acid chloride evaporator 2, where the acyl chloride is circulated in the acid chloride evaporator 2, and the material at the bottom of the evaporator is pumped again Enter tar concentrator 8 and carry out tar concentration. The acid chloride evaporator is a first-stage falling film evaporator, the pressure is controlled at an absolute pressure of 1KPa, and the temperature is controlled at 220°C. The tar concentrator is a molecular still, the pressure is controlled at an absolute pressure of 800 Pa, and the temperature is controlled at 280°C. Continuously operated for 2 hours to obtain stearyl chloride product (c) 293kg, concentrated tar 7kg. The chromaticity of acid chloride product measured by platinum-cobalt colorimetry is 30 HAZEN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com