PVC micro-foaming profile, raw material, preparation method and application of the PVC micro-foaming profile

A micro-foaming and profile technology, applied in covering/lining, building structure, construction, etc., can solve the problem of poor compatibility of PVC micro-foamed composites, poor tensile strength and flexural strength of PVC micro-foamed profiles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

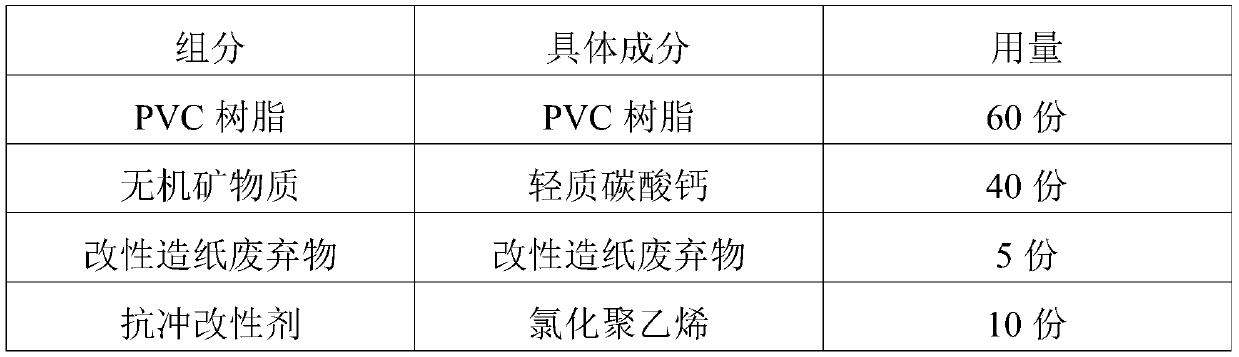

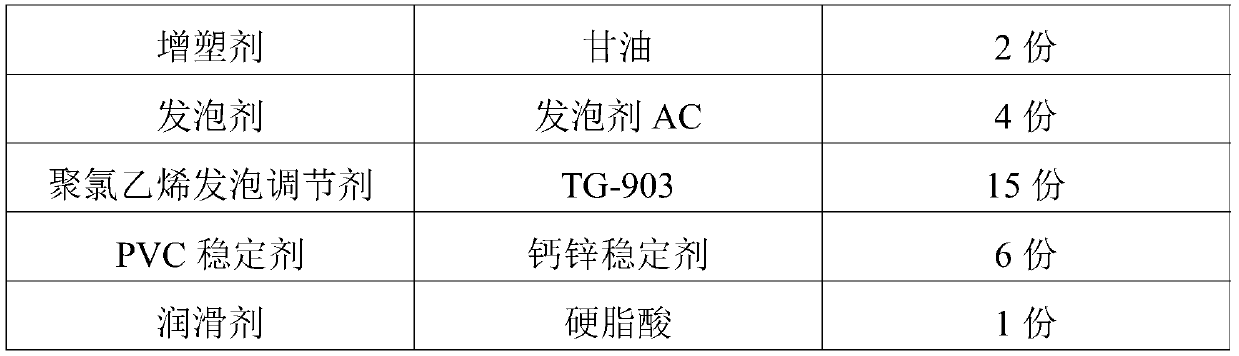

Embodiment 1

[0074] (1) Preparation method of modified papermaking waste:

[0075] In this embodiment, the papermaking black liquor is the papermaking black liquor produced during the pulping process by the caustic soda method. The caustic soda method specifically involves cooking poplar wood with a caustic soda solution. The cooking temperature is 160-180° C. and the cooking time is 3 hours.

[0076] Add sulfuric acid to a certain amount of papermaking black liquor prepared by the above-mentioned caustic soda method to adjust the pH of the system to 3, then dry and sieve to obtain papermaking waste; papermaking waste, stearic acid and cyclodextrin are mixed together Mix in the machine to obtain modified papermaking waste; among them, the particle size of the material after screening is 200 mesh; the mass ratio of papermaking waste to stearic acid is 100:5, and the mass ratio of papermaking waste to cyclodextrin The ratio is 100:0.5; the mixing temperature in the internal mixer is 160°C, t...

Embodiment 2

[0083] (1) Preparation method of modified papermaking waste:

[0084] In this example, the papermaking black liquor is the papermaking black liquor produced during the pulping process using the kraft method. The kraft method specifically uses kraft pulp to cook poplar wood. The cooking temperature is 160-180° C., and the cooking time is 3h.

[0085] Add sulfuric acid to a certain amount of paper-making black liquor obtained by the above-mentioned sulfate method to adjust the pH of the system to 3, then dry and sieve to obtain paper-making waste; The modified papermaking waste was obtained by internal mixing; wherein, the particle size of the material after screening treatment was 200 mesh; the mass ratio of papermaking waste to stearyl chloride was 100:10, and the mass ratio of papermaking waste to pyridine was 100 : 1; the mixing temperature in the internal mixer is 160°C, the mixing time is 120min, and the rotating speed is 200rpm.

[0086] (2) Preparation method of PVC mi...

Embodiment 3

[0092] (1) Preparation method of modified papermaking waste:

[0093] In this example, the papermaking black liquor is the papermaking black liquor produced during the pulping process using the sulfite method, and the sulfite method is specifically to use the sulfite cooking liquor to cook poplar, and the cooking temperature is 160-180°C , cooking time is 4h.

[0094] Add sulfuric acid to a certain amount of papermaking black liquor obtained by the above-mentioned sulfite method to adjust the pH of the system to 3, then dry and sieve to obtain papermaking waste; papermaking waste, benzoyl chloride and pyridine are mixed in the mixer Mix in the machine to obtain modified papermaking waste; wherein, the particle size of the material after screening is 200 mesh; the mass ratio of papermaking waste to benzoyl chloride is 100:30, and the mass ratio of papermaking waste to pyridine is 100:3; the mixing temperature in the internal mixer is 160°C, the mixing time is 120min, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com