A kind of preparation method and application of composite rubber filler

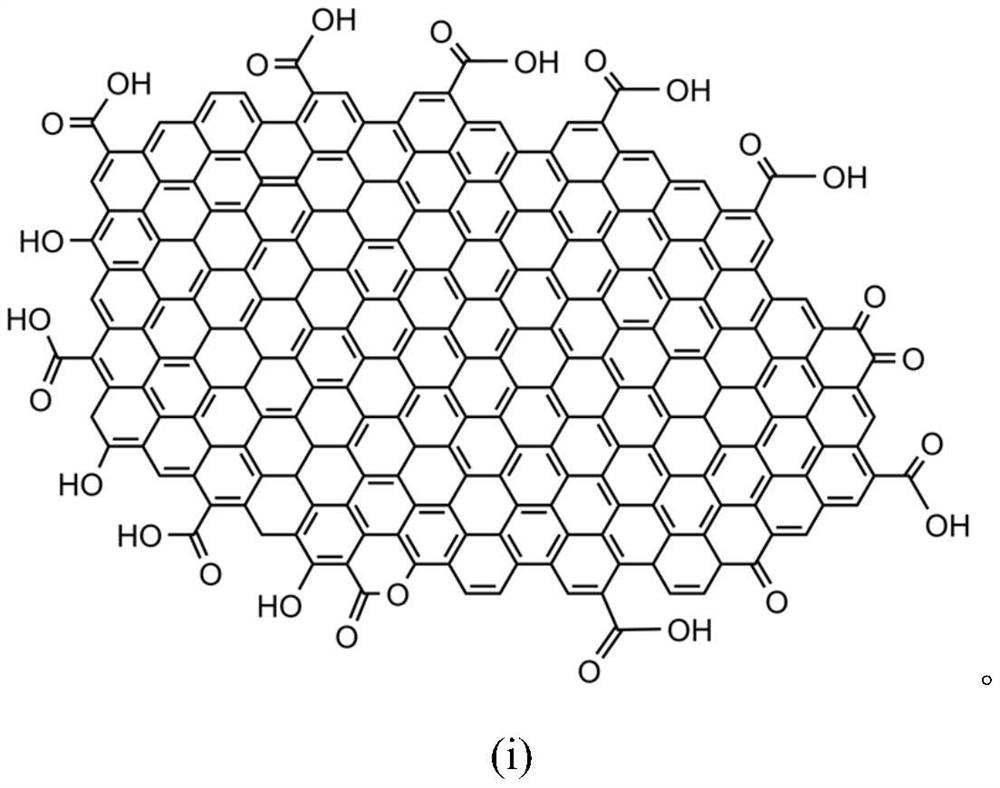

A composite rubber and mixture technology, which is applied in the treatment of fibrous fillers and dyed low-molecular organic compounds, can solve the problems of limited rubber performance improvement, low carboxyl reactivity, poor dispersion performance, etc., and achieve simple operation and good market application The effect of stable value and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

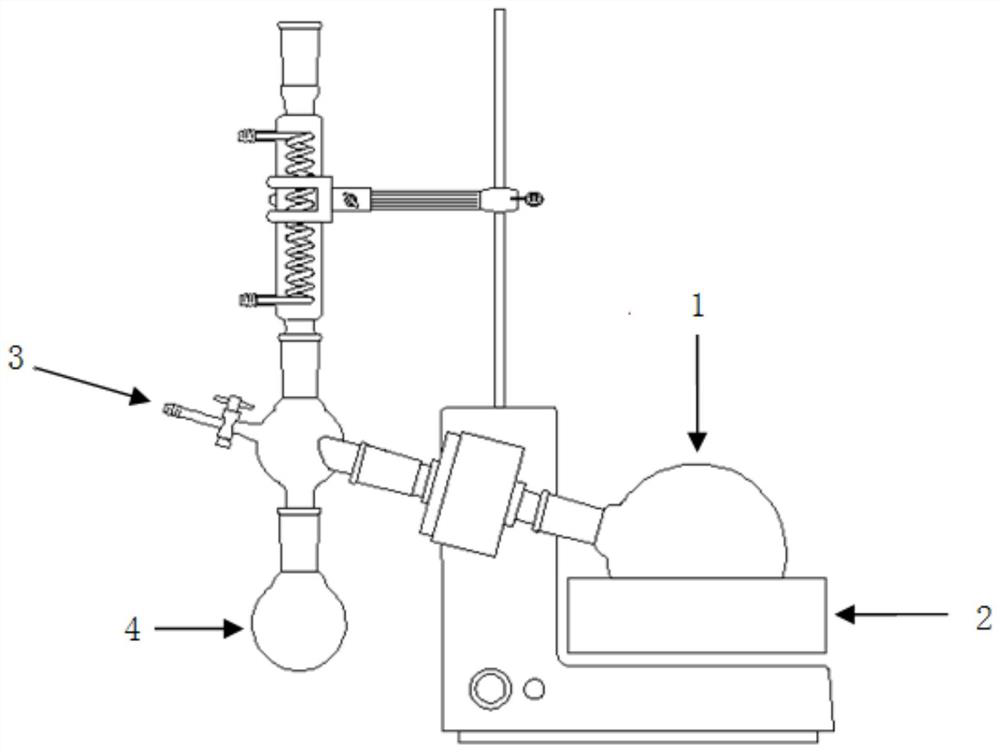

[0035] A kind of preparation method of composite rubber filler, adopts figure 1 The rotary evaporator device in the reaction preparation, the specific preparation method is:

[0036] (1) Add 30g acid carbon black (the mass content of carboxyl group is 0.6-2%), 2g stearic acid, 150g toluene solvent and stir 30min in the reaction vessel 1 of rotary evaporator device, then in reaction vessel 1, drop into 2 Drop DMF and 9g PCl 3 , and the vacuum pump interface 3 is connected to the vacuum device, the rotary evaporator device is evacuated to the vacuum device, and the temperature in the reaction vessel 1 is raised to 55 ° C through the water bath heating device 2, and the reaction is rotated for 3 hours to obtain carbon black modified by acid chloride and A mixture of stearyl chlorides.

[0037] (2) Suspend the reaction device, add 3g of N-cyclohexyl-2-benzothiazole sulfenamide to reaction vessel 1, raise the temperature to 80°C, and react under vacuum for 8h, then continue to he...

Embodiment 2

[0039] Prepare rubber materials according to the formula shown in Table 1. 1# and 2# are carried out by two-stage high-temperature mixing process (in-situ grafted carbon black rubber must be heat-smelted at high temperature, otherwise, the performance is extremely poor), and 3# is carried out by One-stage process at room temperature. Among them, the two-stage high-temperature mixing process in 1# is: adding raw rubber, unmodified carbon black, antioxidant 4020, RD, microcrystalline wax, silane coupling agent and stearic acid into the internal mixer and mixing evenly Finally, raise the temperature of the internal mixer to 160±5°C and heat it for 7 minutes to obtain a first-stage compound rubber; then lower the banbury temperature to below 100°C, add zinc oxide and an accelerator, and mix for 5 minutes to obtain a second-stage compound rubber. Rubber mixing. The two-stage high-temperature mixing process in 2# is: add raw rubber, acyl chloride carbon black, anti-aging agent 4020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com