Alkali lignin micro-nanosphere/paper-based adsorption material, preparation method thereof and application of alkali lignin micro-nanosphere/paper-based adsorption material in dye wastewater treatment

A technology of alkali lignin and micro-nanospheres, which is applied in the fields of adsorption water/sewage treatment, water/sludge/sewage treatment, energy and wastewater treatment, etc. Broad market prospects, large specific surface area, and the effect of not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

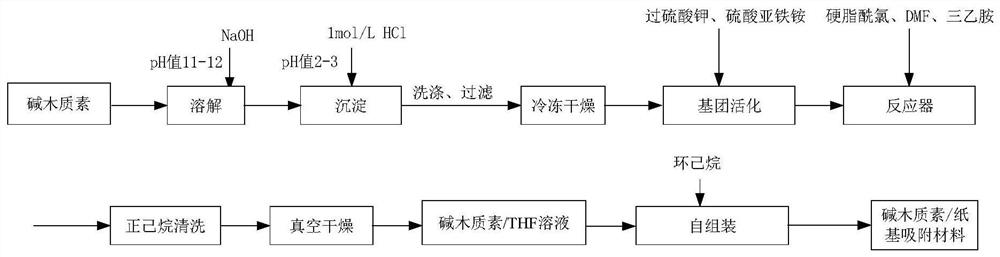

[0070] A method for preparing alkali lignin micro-nanospheres / paper-based adsorption material in this embodiment, the method specifically includes the following steps:

[0071] (1) Purification: Fully dissolve industrial alkali lignin in aqueous sodium hydroxide solution with pH=12, stir for 2 hours, and filter with suction to remove insoluble impurities; Adjust to 2 to fully separate the alkali lignin; filter with suction, wash the obtained filter residue with deionized water until neutral, dry the filter residue at -40°C for 12 hours to constant weight, and grind to obtain 40-60 μm purified alkali lignin white.

[0072] (2) Activation: Potassium persulfate and ammonium ferrous sulfate are dissolved in deionized water according to the proportioning ratio to obtain an initiator solution; then an appropriate amount of purified alkali lignin obtained in step (1) is added to a three-necked flask; Add all the initiator solution into the three-necked flask, raise the temperature o...

Embodiment 2

[0077] A method for preparing alkali lignin micro-nanospheres / paper-based adsorption material in this embodiment, the method specifically includes the following steps:

[0078] (1) Purification: Fully dissolve industrial alkali lignin in aqueous sodium hydroxide solution with pH=12, stir for 2 hours, and filter with suction to remove insoluble impurities; Adjust to 2 to fully separate the alkali lignin; filter with suction, wash the obtained filter residue with deionized water until neutral, dry the filter residue at -40°C for 12 hours to constant weight, and grind to obtain 40-60 μm purified alkali lignin white.

[0079] (2) Activation: Potassium persulfate and ammonium ferrous sulfate are dissolved in deionized water according to the proportioning ratio to obtain an initiator solution; then an appropriate amount of purified alkali lignin obtained in step (1) is added to a three-necked flask; Add all the initiator solution into the three-necked flask, raise the temperature o...

Embodiment 3

[0083] A method for preparing alkali lignin micro-nanospheres / paper-based adsorption material in this embodiment, the method specifically includes the following steps:

[0084] (1) Purification: fully dissolve industrial alkali lignin in aqueous sodium hydroxide solution with pH=11, stir for 3 hours, and filter with suction to remove insoluble impurities; Adjust to 2.5 to fully separate the alkali lignin; filter with suction, wash the resulting filter residue with deionized water until neutral, dry the filter residue at -40°C for 12 hours to constant weight, and grind to obtain 40-60 μm purified alkali lignin white.

[0085] (2) Activation: Potassium persulfate and ammonium ferrous sulfate are dissolved in deionized water according to the proportioning ratio to obtain an initiator solution; then an appropriate amount of purified alkali lignin obtained in step (1) is added to a three-necked flask; Add all the initiator solution into the three-necked flask, raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decolorization rate | aaaaa | aaaaa |

| Decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com