Oil-water separating membrane material as well as preparation method and application thereof

A technology of oil-water separation membrane and oil-water separation device, which is applied in the field of nanomaterials, can solve the problems of cumbersome preparation process, short service life, and low separation efficiency, and achieve good separation effect, good mechanical properties, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

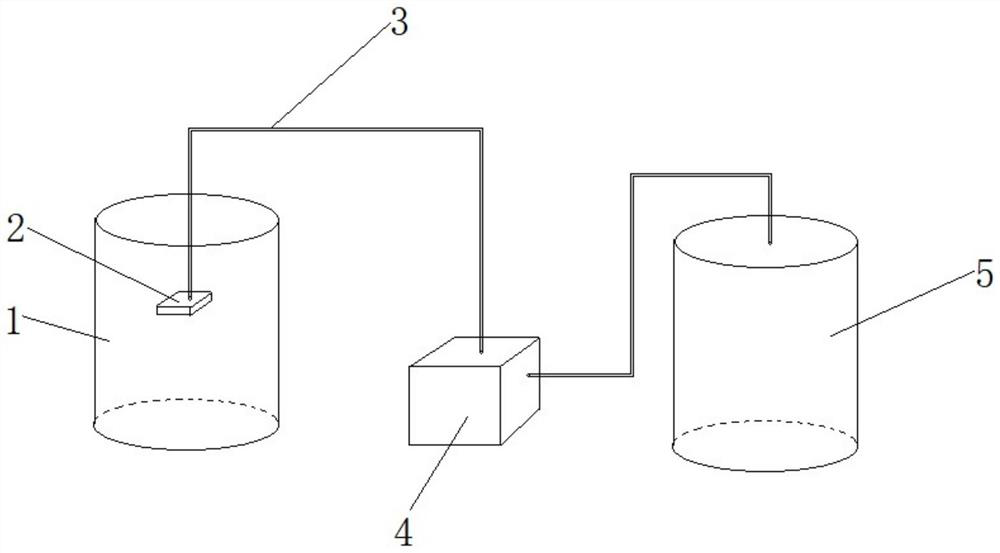

[0053] In a second aspect, the present application provides a method for preparing an oil-water separation membrane material, comprising the following steps:

[0054] S1: Preparation of CuO nanowires;

[0055] S2: Put the CuO nanowires in S1 into the pyrrole monomer solution, carry out the polymerization reaction after stirring, cool, wash and dry after the reaction, and obtain CuO(Cu 2 O) @ppy material;

[0056] S3: Add CuO(Cu 2 O) The @ppy material is soaked in a stearyl chloride solution to obtain an oil-water separation membrane material.

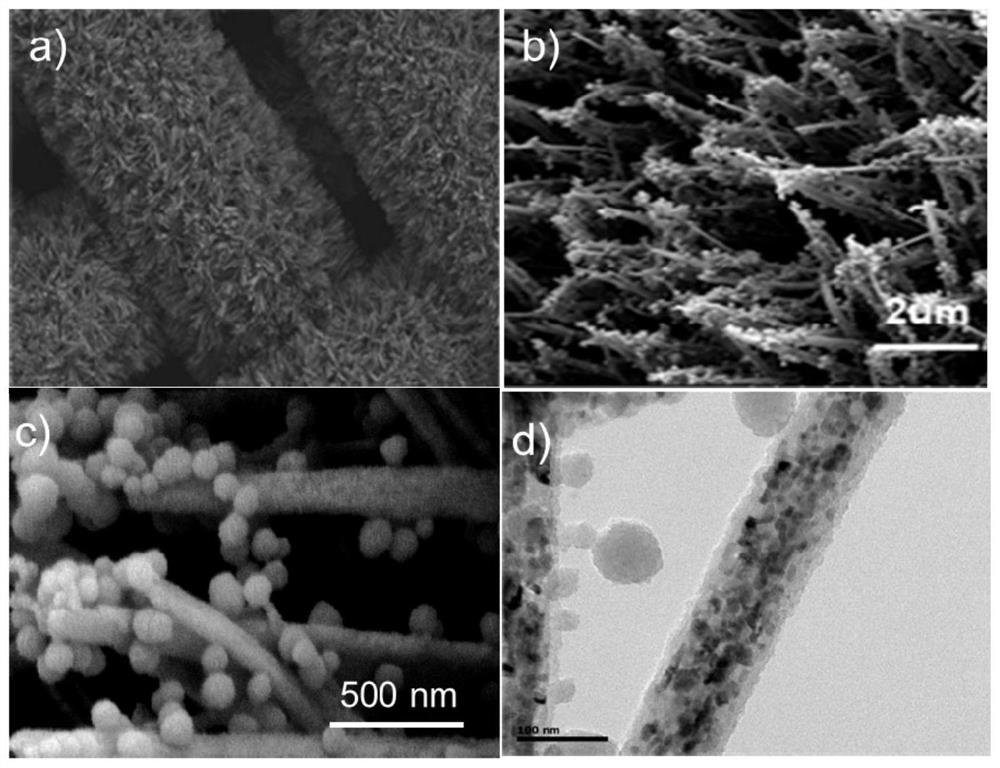

[0057] It should be noted that the solvent of the pyrrole monomer solution is preferably a reducing solvent, including but not limited to absolute ethanol. Under solvothermal conditions, CuO nanowires have good oxidation properties (the reaction converts to Cu 2 O), ethanol has good reducibility (the reaction is transformed into acetaldehyde), and the two generate free radicals through redox reactions, which jointly trigger the in-si...

Embodiment 1

[0080] Using the in-situ chemical etching method, the copper foam is placed in the sodium hydroxide / ammonium persulfate mixture to grow high-density and uniform Cu(OH) 2 nanoarray; the synthesized Cu(OH) 2 The nanoarrays were put into a muffle furnace and calcined at 180°C for 1 h to obtain CuO nanowires with a black-brown array structure. The copper foam covered with CuO nanowires was immersed in 50 mL of pyrrole monomer solution with a volume ratio of 1:80, and then Transfer to a reaction kettle, react at 150°C for 7 hours, take out the sample after the reaction is completed and cool to room temperature, wash with distilled water and ethanol respectively, put it in an oven to dry at 60°C, and then immerse it in 80mL with a volume ratio of 1:12 Soak in stearyl chloride solution at 60°C, take it out after 3 hours, and get superhydrophobic and superlipophilic core-shell structure CuO(Cu 2 O) @ppy material.

[0081] After being irradiated by a sunlight intensity for 10 minutes...

Embodiment 2

[0085] Using the in-situ chemical etching method, the copper foam is placed in the sodium hydroxide / ammonium persulfate mixture to grow high-density and uniform Cu(OH) 2 nanoarray; the synthesized Cu(OH) 2 The nanoarrays were put into a muffle furnace and calcined at 180°C for 1 h to obtain CuO nanowires with a black-brown array structure. The copper foam covered with CuO nanowires was immersed in 50 mL of pyrrole monomer solution with a volume ratio of 1:100, and then Transfer to a reaction kettle, react at 150°C for 5 hours, take out the sample after cooling to room temperature after the reaction, wash with distilled water and ethanol respectively, dry at 60°C, and then immerse it in 80mL of stearyl chloride with a volume ratio of 1:13 Soak in the solution at 60°C, take it out after 4 hours, and get CuO(Cu 2 O) @ppy material.

[0086] After being irradiated by a sunlight intensity for 10 minutes, the CuO(Cu 2 O) The temperature of the @ppy material reaches 77.3°C, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com