Graphene dispersing agent, preparation method thereof and preparation method of graphene

A graphene dispersant and graphene technology, applied in the field of dispersants, can solve the problems of low yield, environmental protection, complicated process, etc., and achieve the effect of simple preparation process, low cost, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Second aspect of the present invention discloses the preparation method of graphene dispersant as described in the first aspect of the present invention, comprises the following steps:

[0036] Add 9-anthracenol and stearyl chloride into the non-protonated solvent to fully dissolve to form a uniform mixed solution;

[0037] After adding lye to the mixed solution, stirring and reacting, purifying and drying to obtain the graphene dispersant.

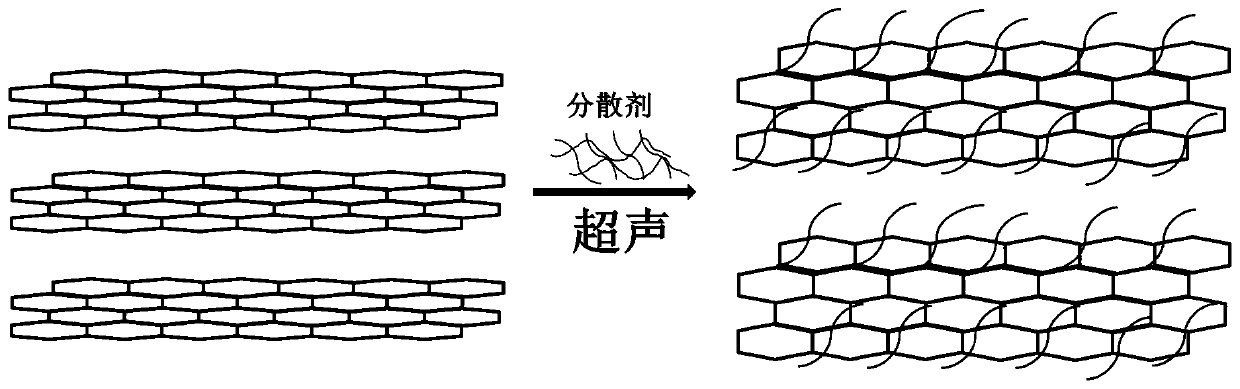

[0038] In the present invention, 9-anthracenol and stearyl chloride are used to prepare a small molecule graphene dispersant containing non-polar anthracenyl and octadecyl hydrophobic segments (9-anthracenol grafted hard Ester acid chloride), its chemical structural formula is as described in one aspect of the present invention, and this graphene dispersant can also improve the quality and productive rate of graphene when exfoliating graphite to form graphene. In some embodiments of the present invention, the finally obtained grap...

Embodiment 1

[0050] Add 10.0g of 9-anthracenol and 20.0g of stearyl chloride into 0.9L of N,N-dimethylformamide, fully dissolve and form a uniform mixed solution; then add 20.0mL of triethylamine to the aforementioned mixed solution, and The reaction was mechanically stirred for 15 h at room temperature, centrifuged and dried to obtain a graphene dispersant.

[0051] 20.0g natural flake graphite (400 mesh), 5.0g graphene dispersant prepared in the present embodiment and ethylene glycol monoethyl ether were added to the reaction vessel and mixed uniformly, and ultrasonic peeling was carried out under the ultrasonic assist (power 200W) for 5h; After the stripping was completed, the product was centrifuged at 3000 rpm for 45 min to obtain a dispersion of upper graphene.

[0052] The graphene dispersion prepared in this embodiment is stable without sedimentation, and the exfoliation rate is 20%.

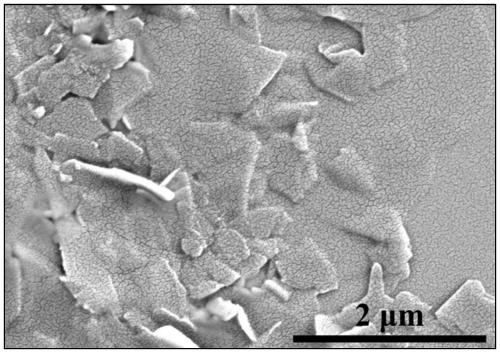

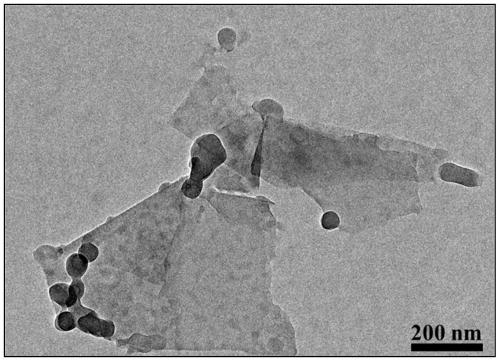

[0053] figure 2 It is the scanning electron micrograph of the graphene that the embodiment of ...

Embodiment 2

[0059] Add 8.0g of 9-anthracenol and 13.0g of stearyl chloride into 0.5L of acetone, fully dissolve and evenly form a uniform mixed solution; then add 15.0mL of ethylenediamine to the aforementioned mixed solution, stir the reaction at room temperature for 18h, centrifuge Post-dry to obtain graphene dispersant.

[0060] 20.0g expanded graphite (400 mesh), 8.0g graphene dispersant prepared in the present embodiment and 1.5L tetrahydrofuran are added to the reaction vessel and mixed uniformly, and ultrasonic stripping is carried out under the assistance of ultrasonic wave (power 100W) for 6h; , the product was centrifuged at 2000 rpm for 60 min to obtain a dispersion of upper graphene.

[0061] The graphene dispersion prepared in this embodiment is stable without sedimentation, and the exfoliation rate is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com