Biodegradable master batch, profile, raw material and preparation method of biodegradable master batch

A technology of biodegradation and masterbatch, applied in the field of raw materials and their preparation, biodegradable masterbatch, profiles, can solve the problems of secondary pollution of the environment, not easy to be degraded, papermaking waste is not efficiently utilized, etc., to achieve improved compatibility Sexuality and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Preparation of modified papermaking waste

[0063] Add sulfuric acid to a certain amount of papermaking black liquor prepared by the conventional caustic soda method to adjust the pH of the system to 3, then dry and sieve to obtain papermaking waste, and the particle size of the material after sieving is 300-1000 mesh . Papermaking waste is mixed with stearyl chloride and pyridine in a high-mixer to obtain modified papermaking waste; the mass ratio of papermaking waste to stearyl chloride is 100:5, and the mass ratio of papermaking waste to pyridine is 100 : 1; the mixing reaction temperature in the high mixer is 120°C, the mixing reaction time is 120min, and the rotating speed is 300rpm.

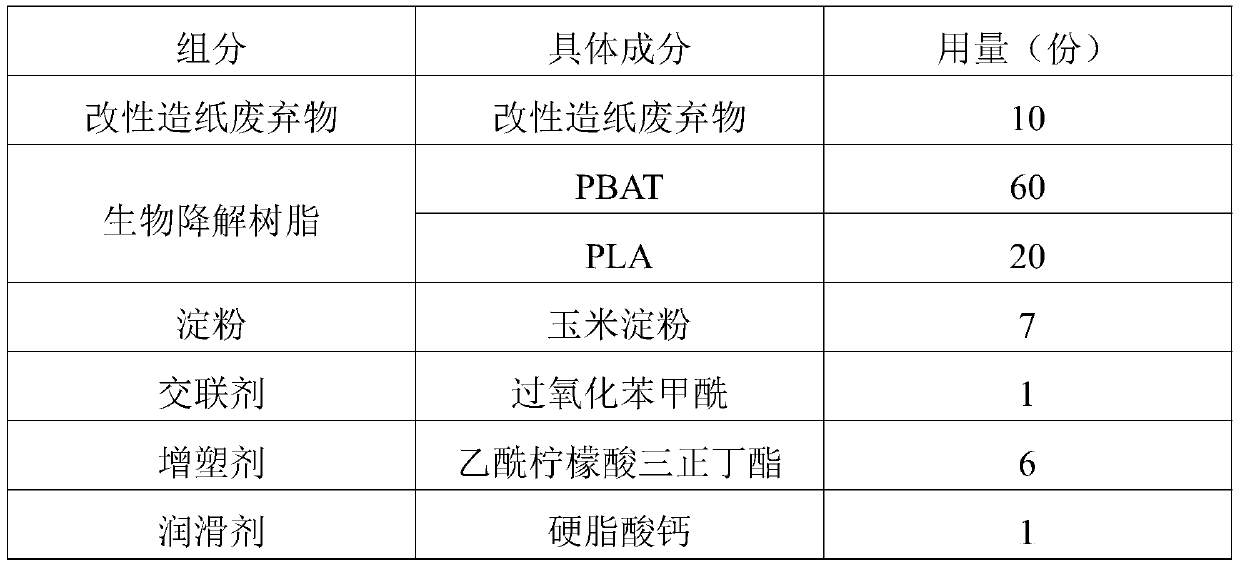

[0064] (2) Preparation of biodegradable masterbatch

[0065] The raw material composition for the preparation of biodegradable masterbatches is added to a high-speed mixer and mixed, and the mixed material is extruded and pelletized in a twin-screw extruder. The temperatures of...

Embodiment 2

[0071] (1) Preparation of modified papermaking waste

[0072] Add sulfuric acid to a certain amount of papermaking black liquor produced by the conventional sulfate method to adjust the pH of the system to 3, then dry and sieve to obtain papermaking waste. The particle size of the material after sieving is 300-1000 head. Papermaking waste is mixed with stearyl chloride and pyridine in a high-mixer to obtain modified papermaking waste; the mass ratio of papermaking waste to stearyl chloride is 100:10, and the mass ratio of papermaking waste to pyridine is 100 : 2; the mixing reaction temperature in the high mixer is 150°C, the mixing reaction time is 180min, and the rotating speed is 500rpm.

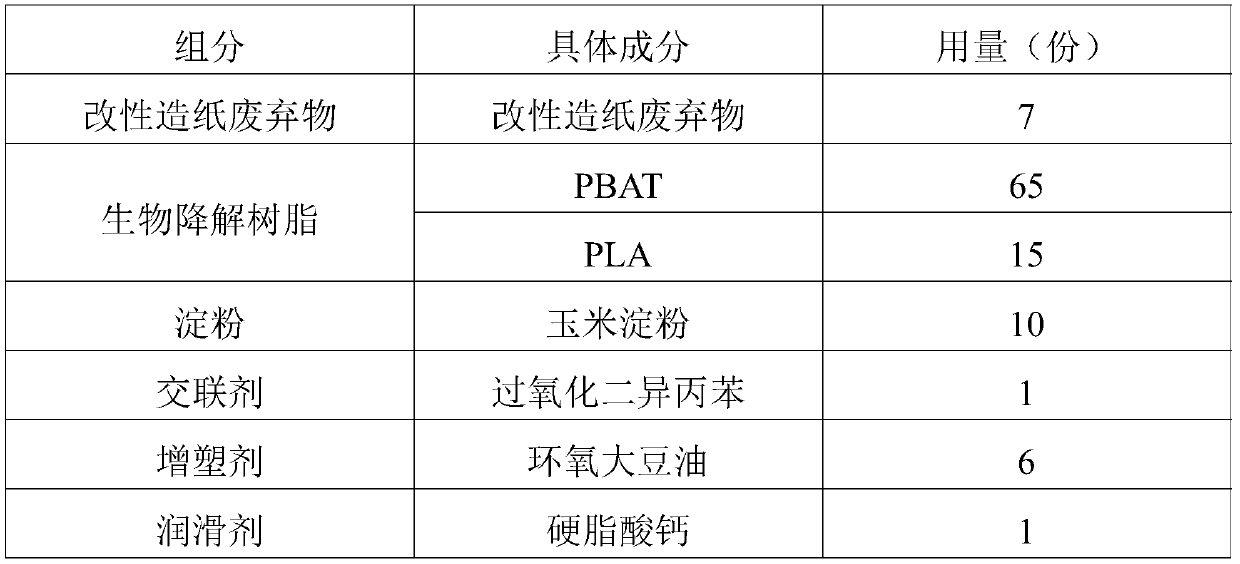

[0073] (2) Preparation of biodegradable masterbatch

[0074] The raw material composition for the preparation of biodegradable masterbatches is added to a high-speed mixer and mixed, and the mixed material is extruded and pelletized in a twin-screw extruder. The temperatures of the firs...

Embodiment 3

[0080] (1) Preparation of modified papermaking waste

[0081] Add sulfuric acid to a certain amount of papermaking black liquor prepared by the conventional sulfite method to adjust the pH of the system to 3, then dry and sieve to obtain papermaking waste, and the particle size of the material after sieving is 500~ 800 mesh. Papermaking waste is mixed with stearyl chloride and pyridine in a high-mixer to obtain modified papermaking waste; the mass ratio of papermaking waste to stearyl chloride is 100:20, and the mass ratio of papermaking waste to pyridine is 100 : 3; the mixing reaction temperature in the high mixer is 150°C, the mixing reaction time is 180min, and the rotating speed is 500rpm.

[0082] (2) Preparation of biodegradable masterbatch

[0083] The raw material composition for the preparation of biodegradable masterbatches is added to a high-speed mixer and mixed, and the mixed material is extruded and pelletized in a twin-screw extruder. The temperatures of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com