A kind of method for continuously producing stearyl chloride

A stearyl chloride, production equipment technology, applied in the direction of chemical instruments and methods, preparation of organic compounds, carboxylate preparation, etc., can solve the problems of harsh reaction conditions, low phosgene utilization rate, slow reaction speed, etc., to achieve accelerated Reaction speed, low tar content, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

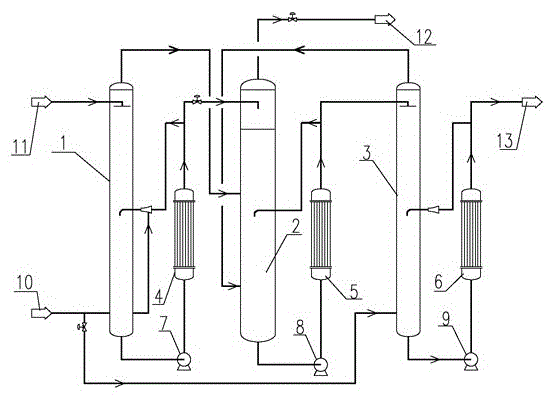

[0030] Example 1, see figure 1 :

[0031] The size of No. 1 bubble tower and No. 3 bubble tower is φ325×800mm, the size of No. 2 bubble tower is φ457×800mm, and the No. 1 and No. 3 circulating pumps used are experimental metering pumps with a flow rate of 1m 3 / h, No. 2 circulating pump is a metering pump for experiments, with a flow rate of 2m 3 / h, the proportion of DMF in the molten stearic acid is 0.8%, placed in a high-level tank with a heat preservation device (temperature is 75 ° C), and continuously flows to the No. 1 bubble column, which is controlled by pipeline valves and flow meters The velocity is 0.035m 3 / h, continuously entering No. 1 bubble tower phosgene is 0.25m 3 / h, continuously entering No. 3 bubble tower phosgene is 0.3m 3 / h, No. 1 heat exchanger, No. 2 heat exchanger and No. 3 heat exchanger use warm water at 60°C. After phosgene is introduced for 0.5 hours, No. 1 bubble tower, No. 2 bubble tower and No. 3 bubble tower The temperature starts to ri...

Embodiment 2

[0032] Example 2, the equipment size is the same as that of Example 1, the operation process is the same as that of Example 1, the reaction temperature is controlled at 65°C, and the sample is taken from the discharge port after continuous operation for 1 hour, and the acid chloride content in the crude acid chloride is 92.63% by potentiometric titration . After 3.0 hours of continuous operation, the content of acid chloride was stabilized above 97.50%, but the color of the obtained crude product of acid chloride was slightly lighter than that of Example 1.

Embodiment 3

[0033] Example 3, the equipment size is the same as in Example 1, the operation process is the same as in Example 1, the reaction temperature is controlled at 85°C, and the sample is taken from the discharge port after continuous operation for 1 hour, and the acid chloride content in the crude acid chloride is 94.92% by potentiometric titration. . After 2.3 hours of continuous operation, the acid chloride content was stable above 97.50%, but the color of the obtained crude acid chloride was slightly darker than that of Examples 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com