High-fluidity ethylene-alpha-octene graft copolymer and preparation method thereof

A graft copolymer, high fluidity technology, applied in the field of modified polymer copolymer and its preparation, can solve the problems of low production cost, reduced fluidity, inconvenient large-scale production, etc., to achieve easy mixing and granulation, Good notched impact performance and short reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

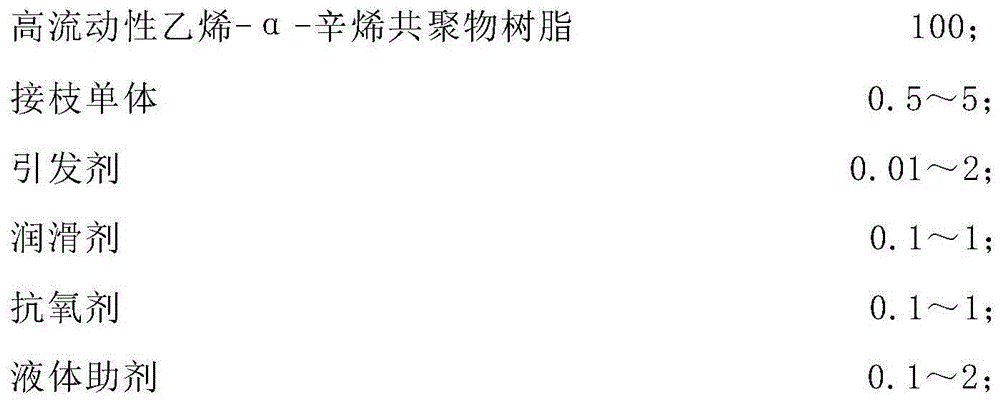

Method used

Image

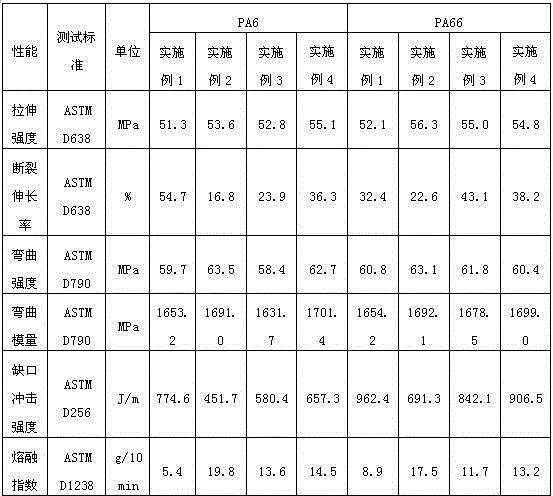

Examples

Embodiment 1

[0031] Weigh the following components in parts by weight: 100 parts of POE resin (DOW, ENGAGE 8200, MI (melt index) = 5.0g / 10min), 2 parts of maleic anhydride as the grafting monomer, and diisopropyl peroxide as the initiator 0.1 part of benzene, 0.3 part of stearate, 0.3 part of 168 / 1010 antioxidant, 0.2 part of wax oil.

[0032] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 5 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feed port to the machine head is set between 100°C and 200°C, the screw speed is controlled at 300 rpm, the screw length-to-diameter ratio is 48:1, and the mixture is melted and plasticized , kneading and mixing, head extrusion, stranding, cooling, pelletizing, and drying to obtain the product.

Embodiment 2

[0034] Weigh the following components in parts by weight: 100 parts of POE resin (DOW, ENGAGE 8402, MI=30.0g / 10min), 3 parts of glycidyl methacrylate as graft monomer, 2,5-dimethyl 0.15 parts of base-2,5-di-tert-butylperoxyhexane and dicumyl peroxide, 0.4 parts of PE wax, 0.4 parts of 1010 and 168 antioxidants, and 0.1 part of white oil.

[0035] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 8 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feeding port to the machine head is set between 80°C and 180°C, the screw speed is controlled at 400 rpm, the length-to-diameter ratio of the screw is 52:1, and the mixture is melted and plasticized , kneading and mixing, head extrusion, stranding, cooling, pelletizing, and drying to ob...

Embodiment 3

[0037] Weigh the following components in parts by weight: 100 parts of POE resin (DOW, ENGAGE 8130 MI=13.0g / 10min), 3 parts of maleic anhydride and glycidyl methacrylate (1:2) for grafting monomer, trigger The agent is 0.2 parts of bis(tert-butylperoxyisopropyl)benzene, 0.4 parts of stearate, 0.4 parts of antioxidants for 1010 and 168, and 0.2 parts of white oil.

[0038] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 3 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feeding port to the machine head is set between 110°C and 220°C, the screw speed is controlled at 200 rpm, the length-to-diameter ratio of the screw is 36:1, and the mixture is melted and plasticized , kneading and mixing, head extrusion, stranding, cooling, pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com