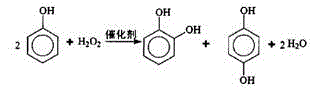

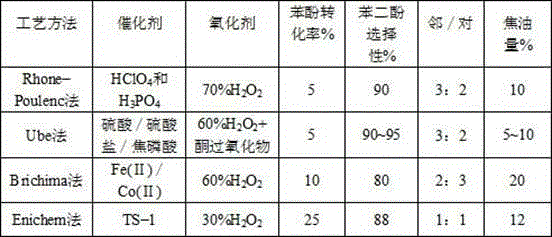

Phenol and hydrogen peroxide hydroxylation microchannel reaction method

A micro-channel reaction, micro-channel reactor technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of cumbersome intermittent operation, affecting competitiveness, large reactor volume, etc. And the effect of fast heat transfer, short reaction residence time and low catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At a temperature of 40°C, 47.5g of phenol, 300mL of water and 4.45g of water-soluble catalyst were added into the reaction flask and stirred evenly, and then 51mL of 30% hydrogen peroxide was quickly added dropwise to make a raw material solution. When the temperature of the microchannel reactor rose to 90° C., the raw material solution was continuously input into the microchannel reactor at a flow rate of 50 mL / min for hydroxylation reaction. The measurement results are shown in Table 2.

Embodiment 2

[0035] At a temperature of 40°C, 48.7g of phenol, 300mL of water and 4.45g of water-soluble catalyst were added into the reaction flask and stirred evenly, and then 71mL of 30% hydrogen peroxide was quickly added dropwise to make a raw material solution. When the temperature of the microchannel reactor rose to 100° C., the raw material solution was continuously input into the microchannel reactor at a flow rate of 60 mL / min for hydroxylation reaction. The measurement results are shown in Table 2.

Embodiment 3

[0037] At a temperature of 40°C, 47.8g of phenol, 300mL of water and 4.45g of water-soluble catalyst were added into the reaction flask and stirred evenly, and then 91mL of 30% hydrogen peroxide was quickly added dropwise to make a raw material solution. When the temperature of the microchannel reactor rose to 110° C., the raw material solution was continuously input into the microchannel reactor at a flow rate of 70 mL / min for hydroxylation reaction. The measurement results are shown in Table 2.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com