Method for preparing maleic anhydride through n-butane

A technology of n-butane and maleic anhydride, which is applied in the field of n-butane to prepare maleic anhydride, can solve the problems of strengthening catalyst heat transfer and mass transfer ability, etc., so as to avoid sudden catalyst deactivation, improve selectivity and yield rate, to avoid the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

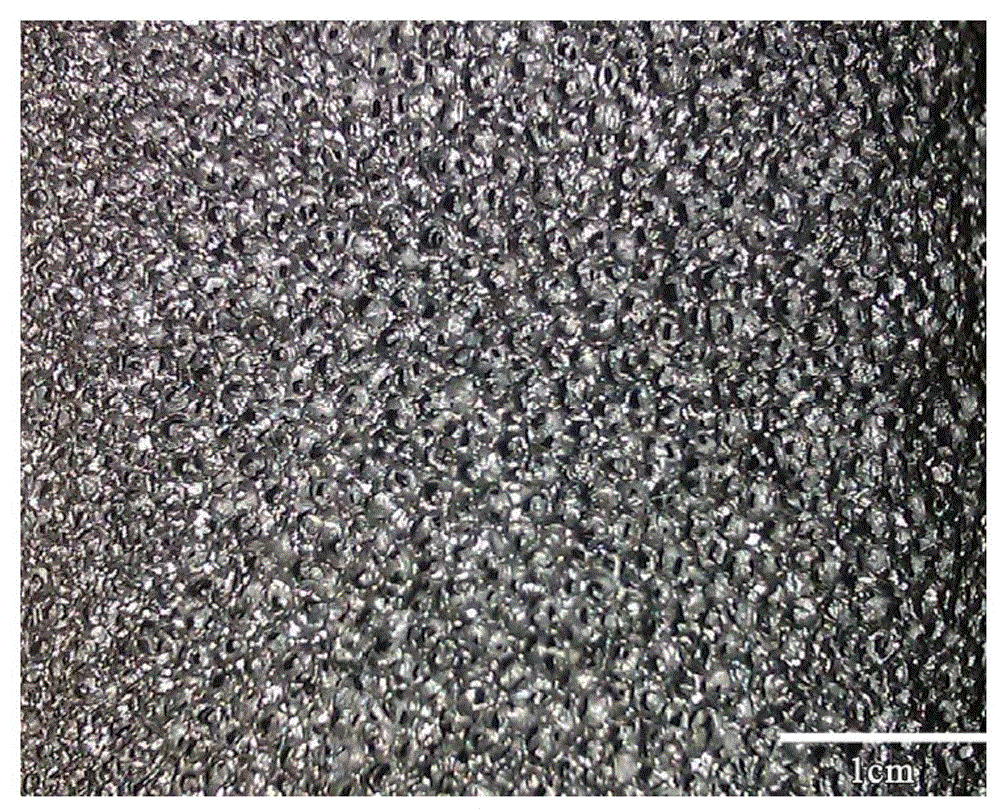

[0045] Preparation of Foamed SiC Ceramic Material

[0046] In the present invention, the foamed SiC ceramic material can use the following preparation method: after cutting the foamed plastic, immerse it in the slurry, after taking it out, remove the excess slurry, semi-cure, and then solidify at high temperature and high pressure; heat the solidified foam solution, to obtain a foamy carbon skeleton composed of SiC and pyrolytic carbon that is the same shape as the original foam; grind the central hole of the carbon skeleton, and use the pressure injection method to inject SiC slurry into the central hole of the carbon skeleton and fill the central hole , and then pyrolyzed; after the siliconizing process, the carbon in the carbon skeleton reacts with gas or liquid silicon to form silicon carbide, which is combined with the original silicon carbide particles in the foam skeleton to obtain high-strength and dense foam SiC ceramics. The silicon carbide foam ceramic of the invent...

Embodiment 1

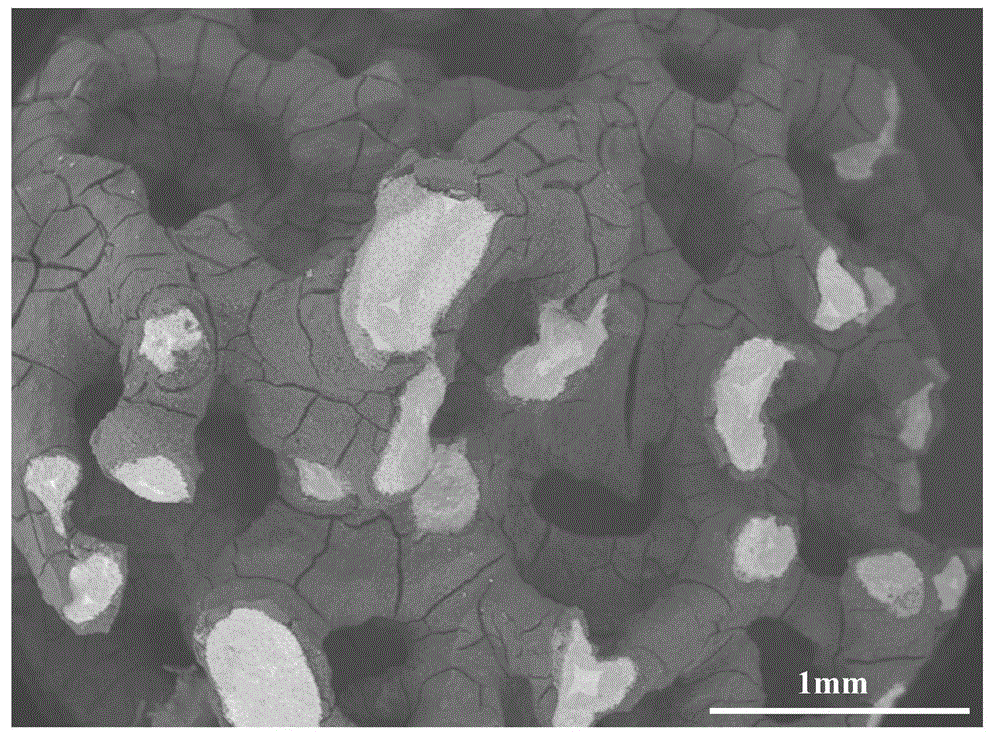

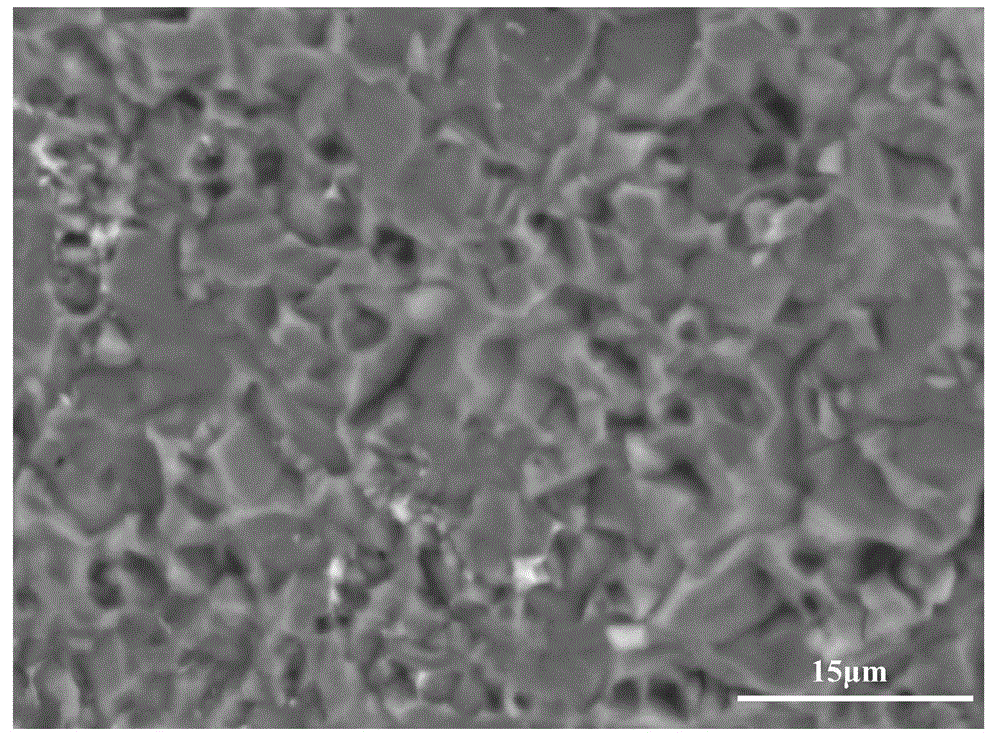

[0054] The catalyst adopts vanadium phosphorus oxide / foam SiC structured catalyst with high intercrystalline porosity, and the catalyst volume is 25mL. The VPO / foam SiC structured catalyst is not modified, the VPO crystal size is 20nm, the P / V atomic ratio is 1.05, the VPO coating thickness is 10 μm, and the VPO crystal loading is 10% by weight. The pore diameter of the foamed SiC carrier is 1 mm, and the porosity is 50%. The specific surface area of vanadium phosphooxygen / foamed SiC structured catalyst is 55.9m 2 g -1 , the micropore surface area is 25.6m 2 g -1 , the outer surface area of the composite material measured by t-plot method is 27.3m 2 g -1 . The vanadium-phosphorus-oxygen crystals in the vanadium-phosphorus-oxygen coating have high intercrystalline porosity, and the volume of mesopores formed by overlapping vanadium-phosphorus-oxygen crystals accounts for 50% of the total pore volume.

[0055] The oxidation reaction of n-butane to maleic anhydride is ...

Embodiment 2

[0057] The catalyst adopts a single-layer vanadium phosphorus oxide / foam SiC structured catalyst, and the volume of the catalyst is 25mL. The VPO / foam SiC structured catalyst is not modified, the VPO crystal size is 100nm, the P / V atomic ratio is 0.89, the VPO coating thickness is 1 μm, and the VPO crystal loading is 5% by weight. The pore diameter of the foamed SiC carrier is 3 mm, and the porosity is 85%. The specific surface area of vanadium phosphooxygen / foamed SiC structured catalyst is 15.5m 2 g -1 , the micropore surface area is 8.6m 2 g -1 , the outer surface area of the composite material measured by t-plot method is 7.2m 2 g -1 . The vanadium-phosphorus-oxygen crystals in the vanadium-phosphorus-oxygen coating have high intercrystalline porosity, and the volume of mesopores formed by overlapping vanadium-phosphorus-oxygen crystals accounts for 30% of the total pore volume.

[0058] The oxidation reaction of n-butane to maleic anhydride is carried out in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com