A Diffusion Method of Buffer Layer

A diffusion method and buffer layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult control of parameter influence, long advancing diffusion time, and low efficiency, achieving low cost and short advancing diffusion time. , the effect of high efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in more detail below in conjunction with the accompanying drawings.

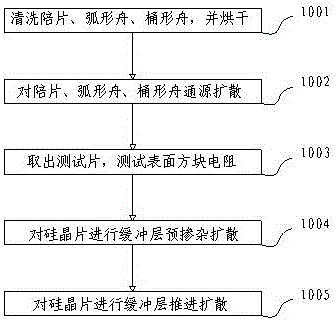

[0030] figure 1 The schematic flowchart shown includes step 1001, step 1002, step 1003, step 1004 and step 1005, which are described in detail as follows.

[0031] Step 1001: Cleaning multiple companion wafers, multiple silicon wafers, arc boats and barrel boats.

[0032] According to the conventional cleaning process, clean multiple accompanying sheets, arc-shaped boats, and barrel-shaped boats. The accompanying sheets and arc-shaped boats are made of conventional N-type single crystal or quartz materials, and the barrel-shaped boats are made of conventional N-type single crystal, polycrystalline, or quartz materials. kind of. If the companion piece is of quartz material, a test piece of silicon material shall be prepared; if t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com