Method for preparing methoxyacetone by using microreaction device

A technology of a micro-reaction device and methoxyacetone, applied in the chemical industry, can solve the problems of incapable of continuous production automation, complex catalysts, expensive use, etc., and achieves the advantages of avoiding the use of complex catalysts, easy preparation process and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

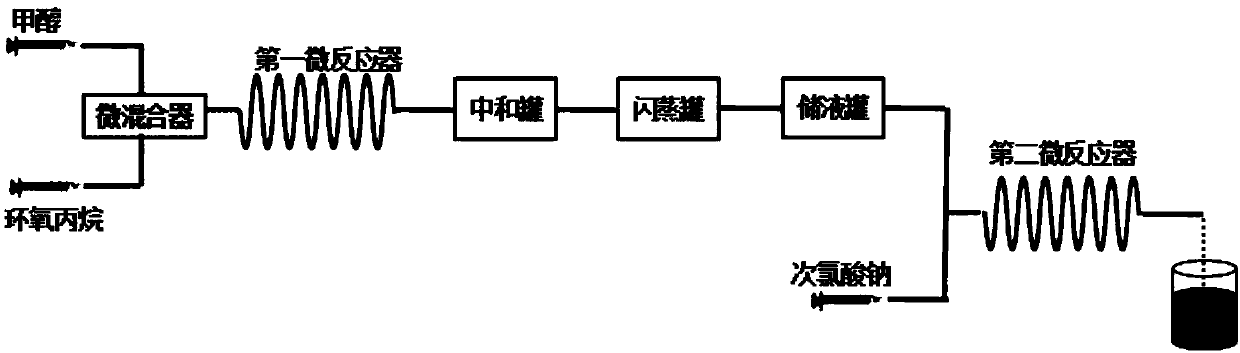

Embodiment 1

[0029] Mix methanol and potassium hydroxide to obtain a methanol solution, the mass fraction of potassium hydroxide in the methanol mixture is 0.5wt%, then pump the propylene oxide and methanol solution into the micro-mixer in the micro-reaction device, and mix thoroughly The mixed system is pumped into the first microreactor in the microreactor for reaction. The molar ratio of propylene oxide to methanol is 1:3, the reaction temperature is 100°C, and the reaction residence time is 5min. The 1-methoxyl group produced by the reaction After the crude product of -2-propanol is neutralized by phosphoric acid and concentrated by flash evaporation, the pure product of 1-methoxy-2-propanol is obtained with a yield of 95%; 1-methoxy-2-propanol and sodium hypochlorite aqueous Pumped into the second microreactor in the microreaction device, wherein the pH of the sodium hypochlorite aqueous solution is 3 to 4 by using dilute hydrochloric acid, the mol ratio of 1-methoxyl-2-propanol and so...

Embodiment 2

[0031] Mix methanol and potassium hydroxide to obtain methanol solution, the mass fraction of potassium hydroxide in methanol mixed solution is 0.8wt%, then pump propylene oxide and methanol solution into the micro mixer in the micro reaction device, mix thoroughly The mixed system is pumped into the first microreactor in the microreaction device for reaction. The molar ratio of propylene oxide to methanol is 1:5, the reaction temperature is 120°C, and the reaction residence time is 7min. The 1-methoxyl group produced by the reaction After the crude product of -2-propanol is neutralized by phosphoric acid and concentrated by flash evaporation, the pure product of 1-methoxy-2-propanol is obtained with a yield of 99%; 1-methoxy-2-propanol and sodium hypochlorite aqueous solution Pumped into the second microreactor in the microreaction device, wherein the pH of the sodium hypochlorite aqueous solution is adjusted to be 3~4 by using dilute hydrochloric acid, the mol ratio of 1-meth...

Embodiment 3

[0033]Mix methanol and potassium hydroxide to obtain a methanol solution, the mass fraction of potassium hydroxide in the methanol mixture is 1wt%, then pump the propylene oxide and methanol solution into the micro-mixer in the micro-reaction device, and mix thoroughly The system is pumped into the first microreactor in the microreactor for reaction. The molar ratio of propylene oxide to methanol is 1:8, the reaction temperature is 130°C, and the reaction residence time is 8min. The 1-methoxy- The crude product of 2-propanol is neutralized by phosphoric acid and concentrated by flash evaporation to obtain the pure product of 1-methoxy-2-propanol with a yield of 96%; pump 1-methoxy-2-propanol and sodium hypochlorite aqueous solution Into the second microreactor in the microreaction device, wherein by using dilute hydrochloric acid to regulate the pH of sodium hypochlorite aqueous solution to be 3~4, the mol ratio of 1-methoxyl group-2-propanol and sodium hypochlorite is 1: 4, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com