Sulfonation reaction tail gas processing apparatus and application thereof

A technology for sulfonation reaction and treatment device, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of polluted environment and low removal rate of oil mist from exhaust gas, and achieves no secondary pollution and shortens the reaction. Residence time, the effect of reducing reaction losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

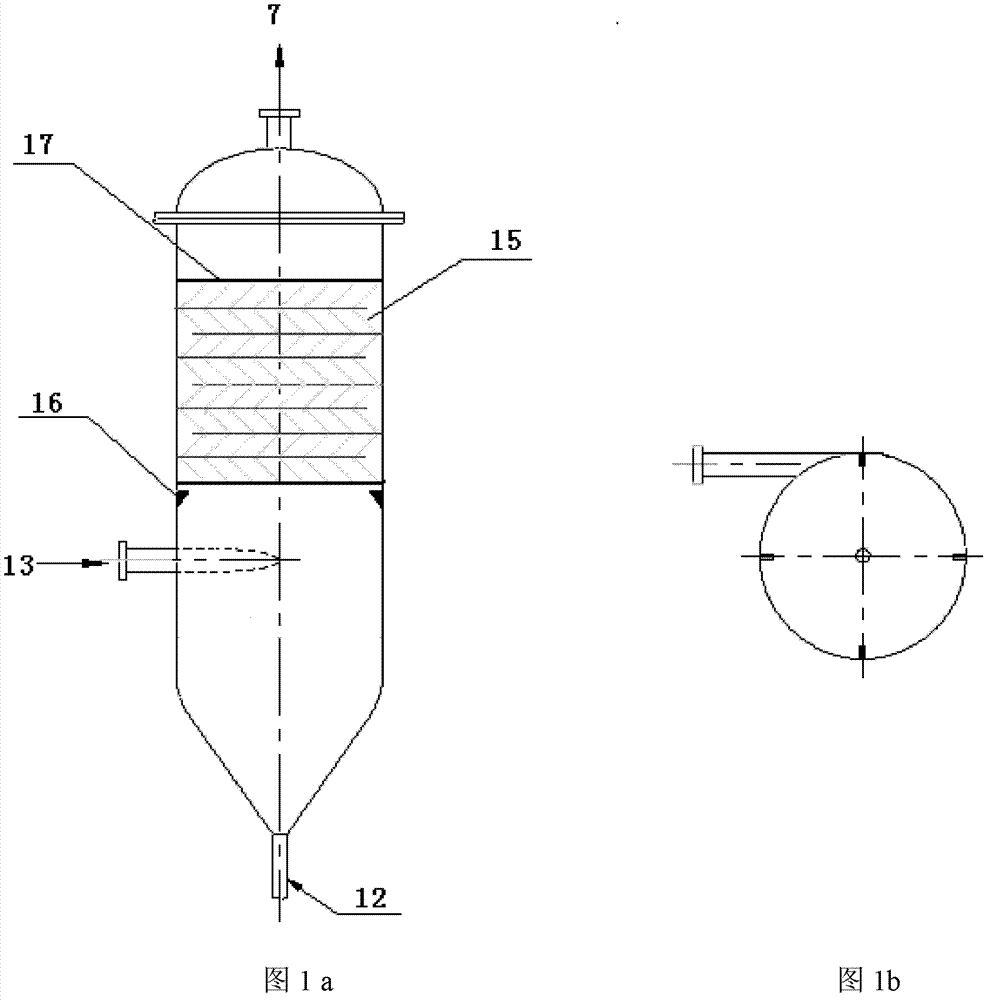

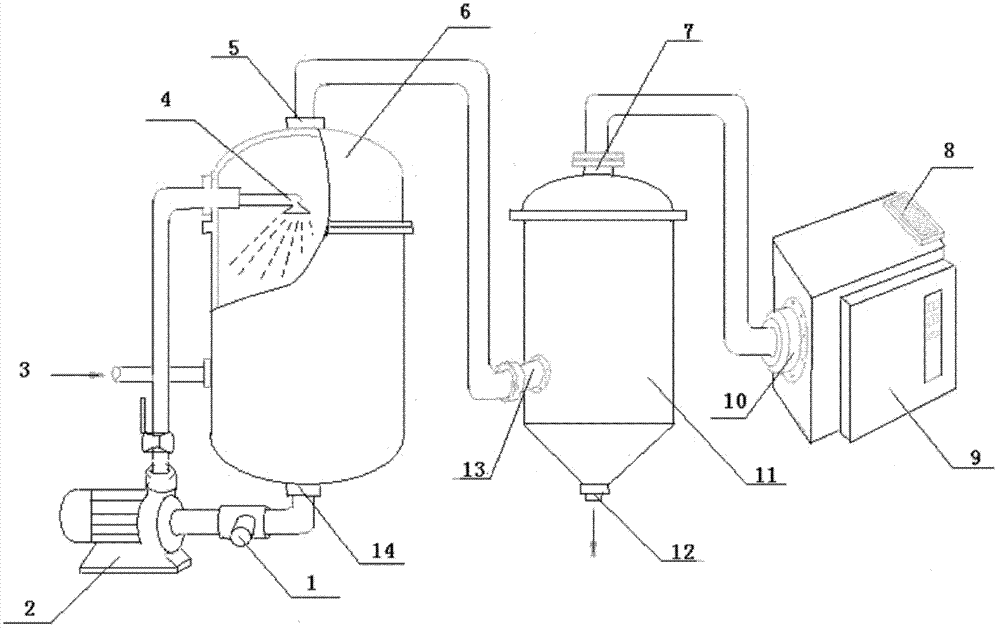

[0021] The particles after the spray mist film sulfonation reaction are fine, with a particle size of 1 μm and a specific resistance of 10 3 Ohm cm, density 895kg / m 3 , SO 3 The acidic sulfonated tail gas with a gas content of 0.3wt% enters the alkali washing tank 6 from the air inlet pipe 3; the alkali aqueous solution is transported from the bottom of the tank to the alkali spray on the upper part of the tank with a concentration of 8wt% through the metering pump 2 through the alkali solution port 1 The head 4 is sprayed downwards and fully contacted with the tail gas of the sulfonation reaction in reverse to absorb and remove the residual sulfur trioxide until the SO in the tail gas after alkali washing 3 Until the gas concentration is less than 0.08wt%, the solution after alkali washing can be recycled through the alkali liquor circulation outlet 14. The tail gas after alkali washing is discharged from the tail gas outlet 5, and enters the cyclone separator 11 tangential...

Embodiment 2

[0023] The particles after the continuous tank sulfonation reaction are fine, with a particle size of 1 μm and a specific resistance of 10 3 Ohm cm, density 887.9kg / m 3 , SO 3The acidic sulfonated tail gas with a gas content of 3wt% enters the alkali washing tank 6 from the air inlet pipe 3; the alkali aqueous solution is transported from the alkali solution port 1 to the alkali spray head on the upper part of the tank through the metering pump 2 with a concentration of 10wt% 4. Spray downwards and fully contact with the tail gas of the sulfonation reaction in reverse to absorb and remove the residual sulfur trioxide until the SO in the tail gas after alkali washing 3 Until the gas concentration is less than 0.08wt%, the solution after alkali washing can be recycled through the alkali liquor circulation outlet 14. The tail gas after alkali washing is discharged from the tail gas outlet 5, and enters the cyclone separator 11 tangentially through the inlet pipe 13 at a flow ra...

Embodiment 3

[0025] The particles after sulfur trioxide membrane sulfonation reaction are fine, with a particle size of 1 μm and a specific resistance of 10 3 Ohm cm, density 887.6kg / m 3 , SO 3 The acidic sulfonated tail gas with a gas content of 1.2wt% enters the alkaline washing tank 6 from the air inlet pipe 3; the alkaline aqueous solution is transported from the bottom of the tank to the lye on the upper part of the tank through the metering pump 2 with a concentration of 9 wt% from the lye port 1 The spray head 4 is sprayed downwards and fully contacted with the tail gas of the sulfonation reaction in reverse to absorb and remove the residual sulfur trioxide until the SO in the tail gas after alkali washing 3 Until the gas concentration is less than 0.08wt%, the solution after alkali washing can be recycled through the alkali liquor circulation outlet 14. The tail gas after alkali washing is discharged from the tail gas outlet 5, and enters the cyclone separator 11 tangentially thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com