Tubular electrolytic cell for domestic sewage treatment

A technology for domestic sewage and electrolysis cells, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of short reaction residence time, protection of marine environment, and reduction of required space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

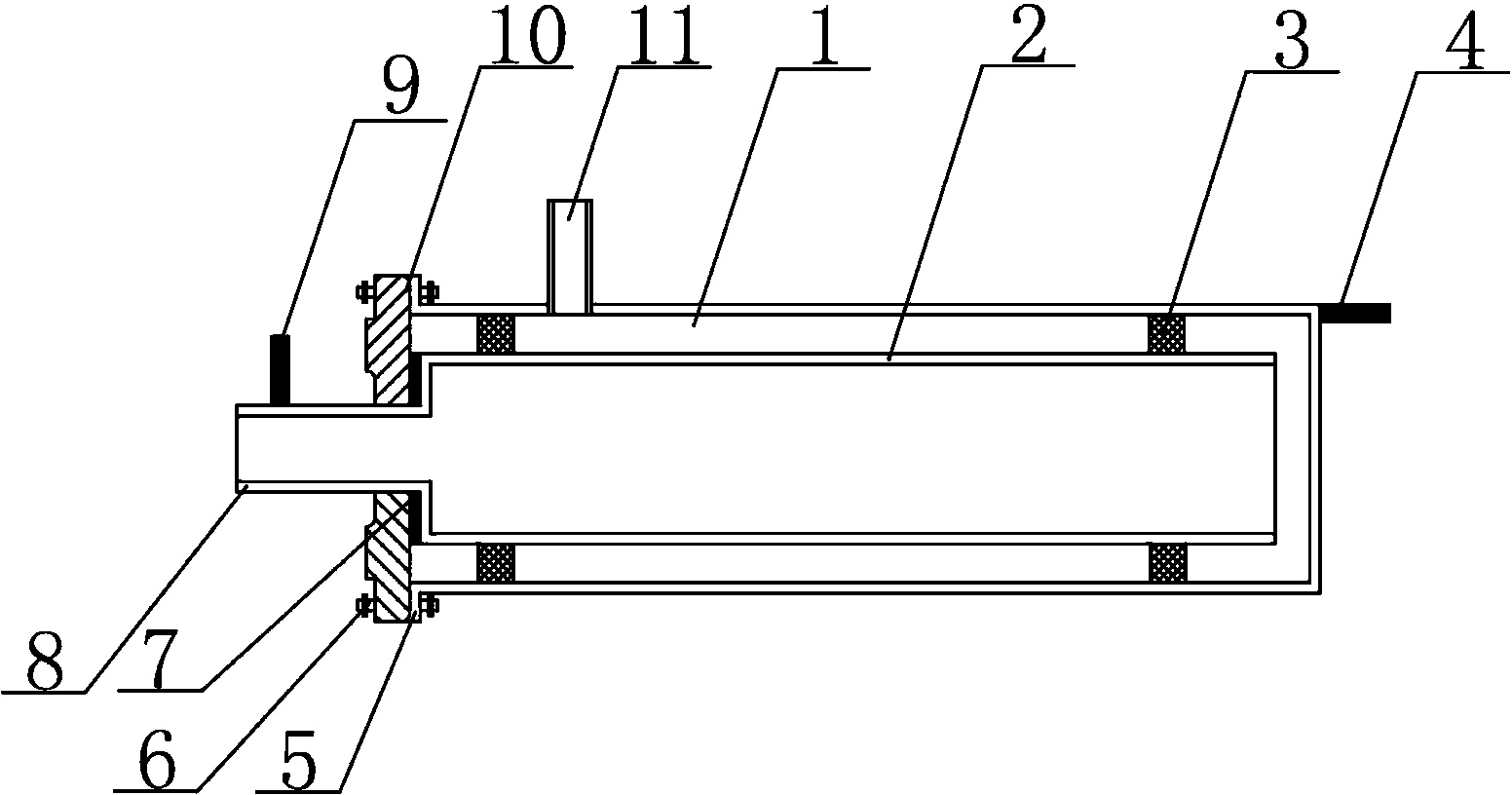

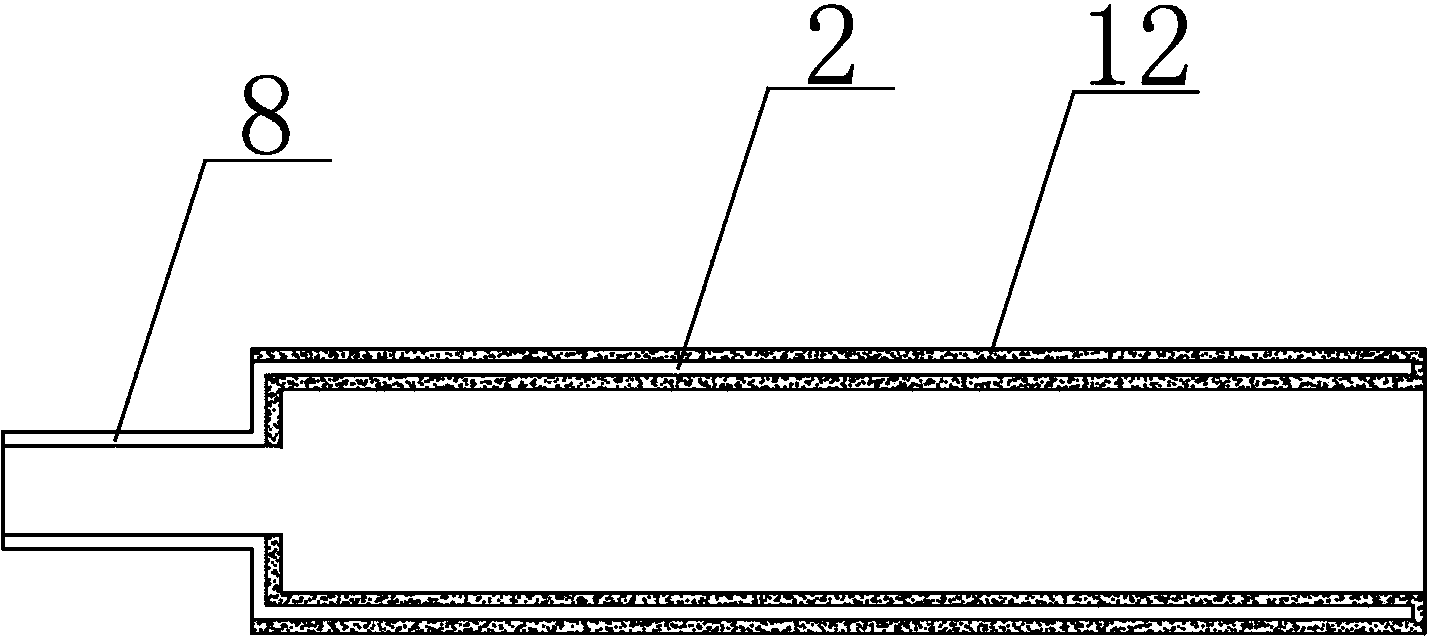

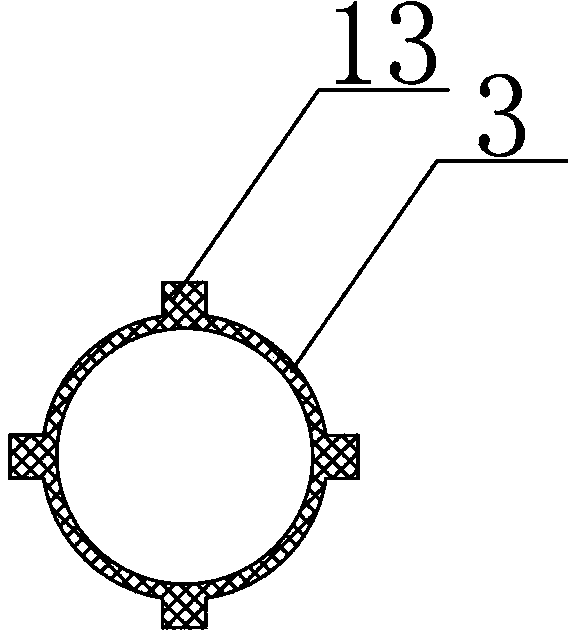

[0013] See attached figure 1 , the present invention is formed by a cathode outer tube 1 and an anode inner tube 2. The cathode outer tube 1 is a titanium tube sealed at one end, and the other end is provided with a nozzle flange 5 and a water inlet connector 11. The water inlet connector 11 It is vertically arranged with the cathode outer tube 1; the anode inner tube 2 is a pipe section with a water outlet connecting pipe 8 at one end, and the outer surface of the pipe section is provided with a ruthenium coating 12, and the water outlet connecting pipe 8 and the anode inner pipe 2 are arranged in concentric circles; The anode inner tube 2 is fixedly set in the cathode outer tube 1 by a tetrafluoroethylene support member 3, and its outlet pipe 8 is set with a tetrafluoroethylene gasket 7, and then is fixedly connected by a flange cover 10 and a nozzle flange 5 with bolts; the cathode A cathode wiring board 4 is arranged on the port sealing plate of the outer tube 1 .

[0014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com