Immersed iron carbon micro electrolysis reactor

An iron-carbon micro-electrolysis and reactor technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unfavorable system long-term operation, iron-carbon bed blockage, hardening, etc. , achieve the effects of short reaction residence time, small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

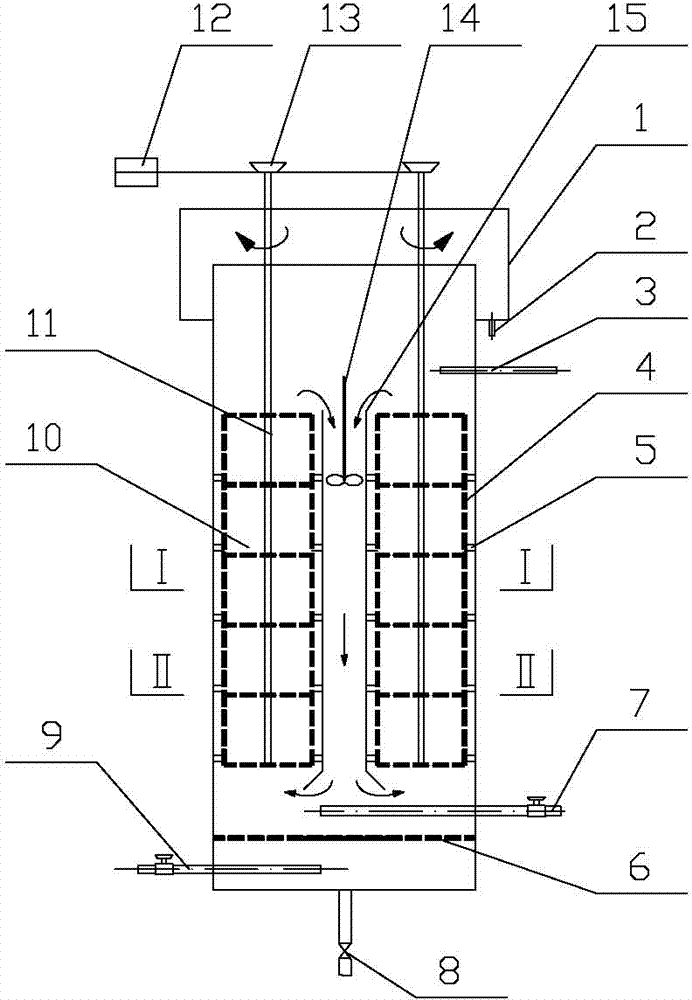

[0022] The present invention will be further described below in conjunction with accompanying drawing:

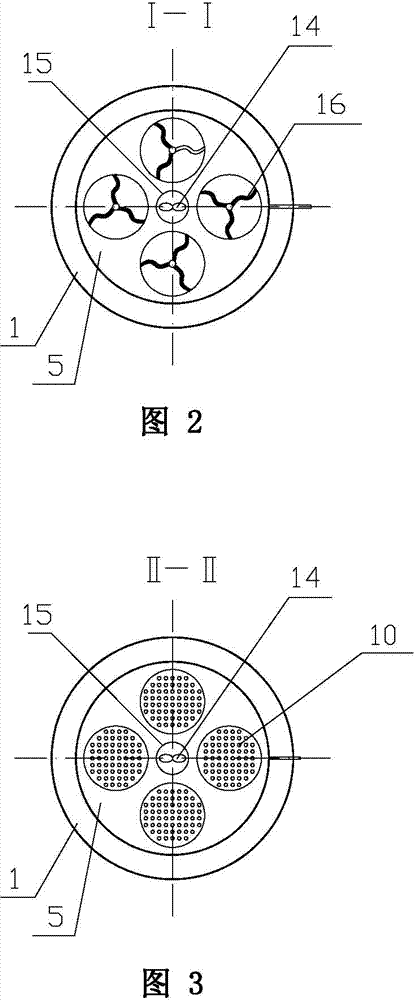

[0023] Such as figure 1 As shown, the present invention is provided with a centrally symmetrical even number of porous cylinders 4 inside the reactor cylinder 1 , and the present invention will take four porous cylinders 4 as an example below. 50-70% volume ratio iron-carbon filler is placed in the porous cylinder 4, and the iron-carbon particle size is 1.5-3mm.

[0024] As shown in Figure 2, a central cylinder 15 is arranged among the four porous cylinders 4, the inner diameter of the central cylinder 15 is 1 / 6 to 1 / 3 of the inner diameter of the reactor cylinder 1, and the inclination angle of the hypotenuse at the lower end is 45°. ° . An agitator 14 is installed in the central cylinder 15, and the agitator 14 is arranged on the upper part of the central cylinder 15. The rotation of the agitator 14 generates a negative pressure to form a circulating water flow from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com