Method for comprehensive processing garbage of food and recycling to use

A comprehensive treatment and meal waste technology, applied in the direction of anaerobic digestion treatment, application, solid waste removal, etc., can solve the problems of imperfect treatment in all directions, achieve huge economic benefits and social effects, and eliminate secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

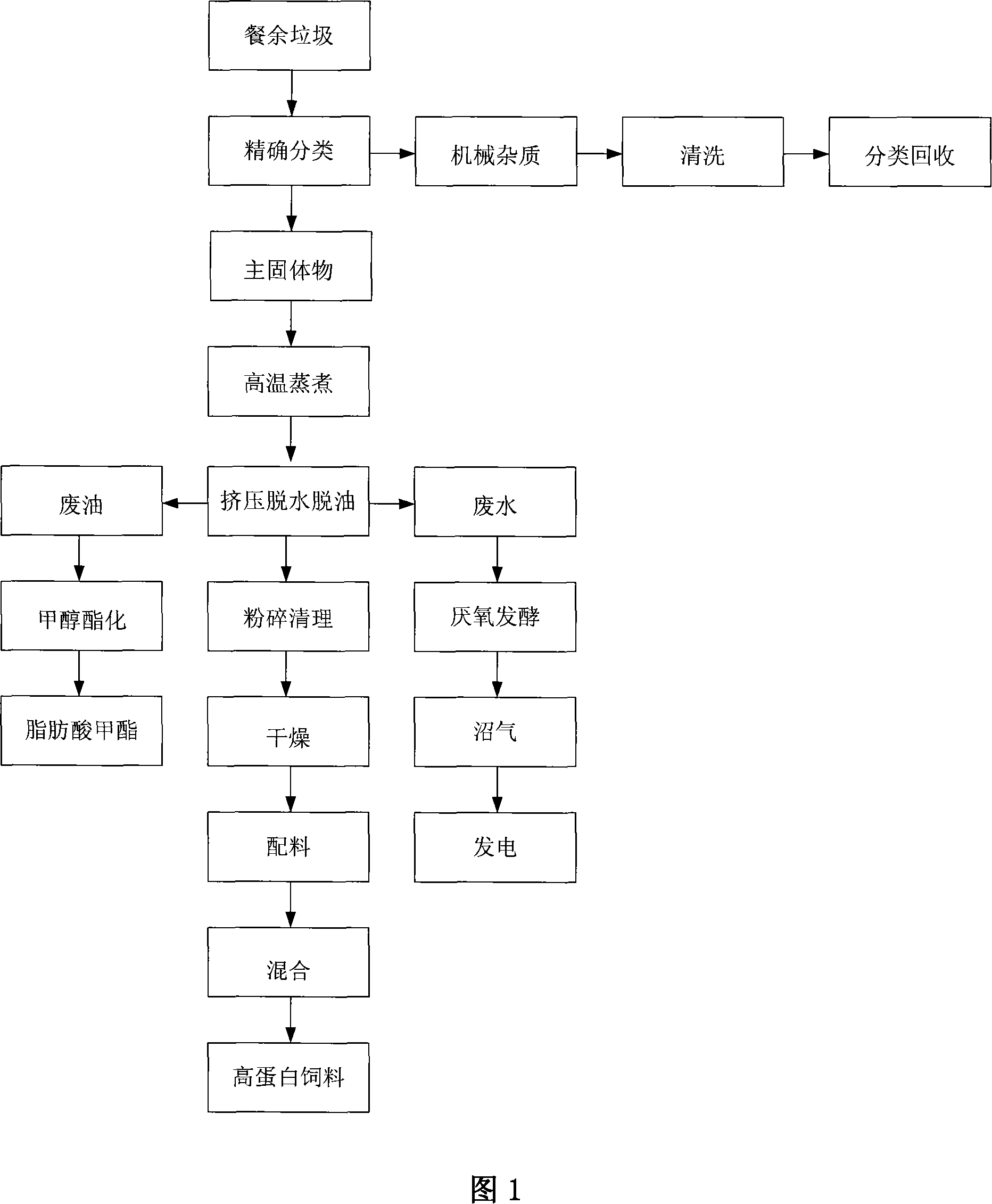

[0028] Catering waste consists of leftovers, packaging bags, discarded tablecloths, disposable chopsticks, toothpicks, bottle caps and other materials. The method for the comprehensive treatment, recycling and reuse of meal waste of the present invention is to carry out comprehensive harmless and resourceful treatment of meal waste, including the following steps: ①accurate classification, ②cleaning and recycling of impurities, ③high-temperature cooking, ④extruding and dehydrating Deoiling, ⑤ waste water treatment, ⑥ waste oil treatment.

[0029] Steps ① and ② are accurate classification and cleaning and recycling of impurities. Use bag breaking machine, vibrating screen, and magnetic separation device to separate packaging bags, large-shaped substances and ferromagnetic substances. Recycling.

[0030] Steps ③ and ④ are to cook the separated material at high temperature and extrude to dehydrate and deoil to separate the solid and liquid, and use physical centrifugal technology...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com