Process for non-catalytically producing biodiesel fuel without yielding by-product

a biodiesel and non-catalytic technology, applied in the direction of fuels, fatty acid chemical modification, fatty oil/acid recovery from waste, etc., can solve the problems of inability to utilize glycerin as heat source, superfluous supply of glycerin, and lack of such a technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

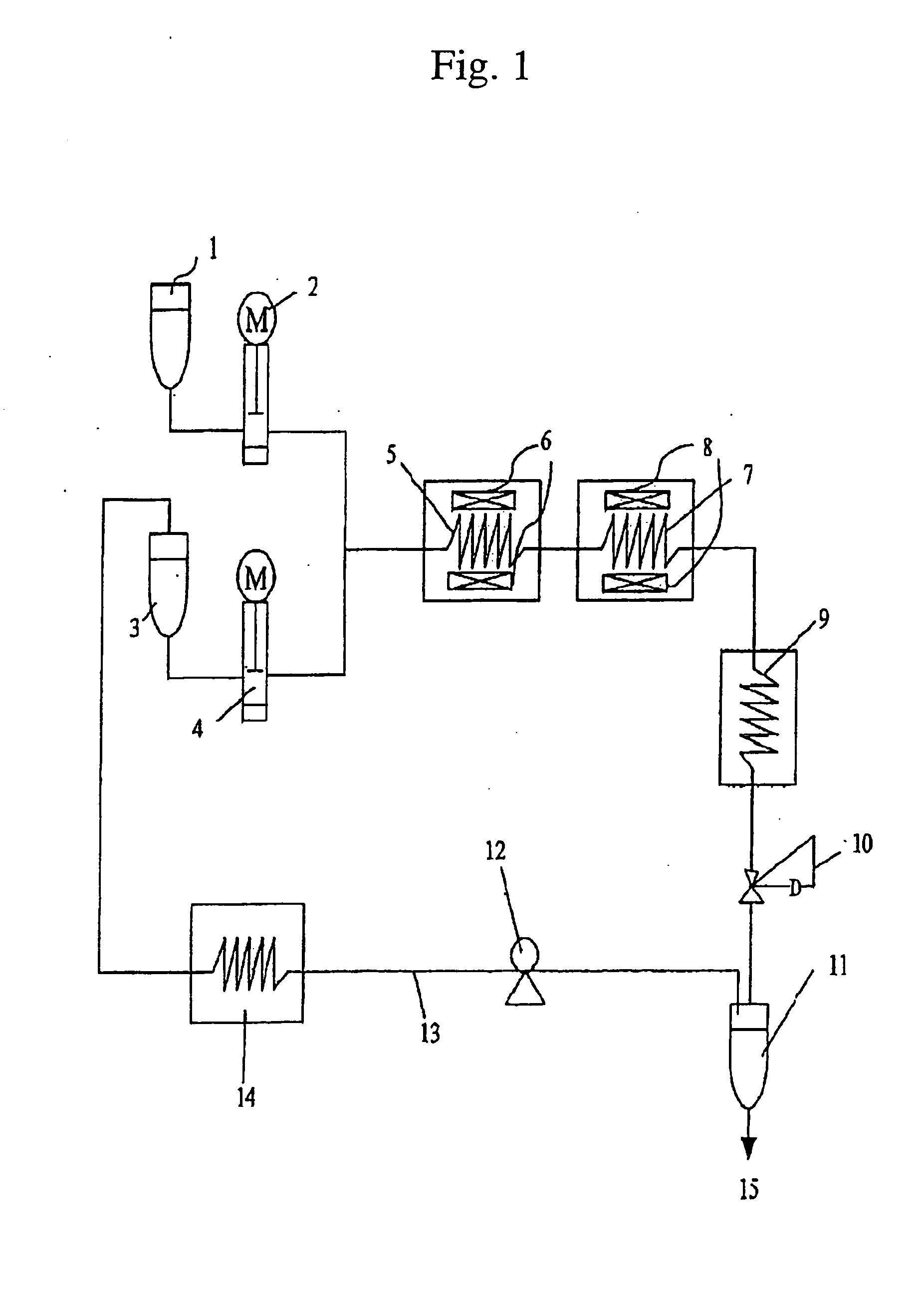

[0055] According to the procedure described below, biodiesel fuel was produced from commercially available canola oil using the apparatus shown in FIG. 1. A coil form HC-22 reaction tube (Hastelloy C; inner diameter: 1.8 mm; length: 7.8 m; interior volume: approximately 20 ml; Mitsubishi Materials Corporation) was used.

[0056] Canola oil (Oilio®, Nisshin OilliO, Ltd.) was placed in a tank 1 for starting materials and methanol (reagent chemicals, Wako Pure Chemical Industries, Ltd.) was placed in a tank 2 for starting materials. A delivery pump was adjusted so that the mixing ratio of canola oil to methanol became 2:1. The temperature in the reaction tube was 395° C., the pressure therein was 40 MPa, the time necessary for passing through the reaction tube was 4 minutes, and the temperature at the time of injection was 270° C. Given the circumstances, the resulting biodiesel fuel was comprised of approximately 50% various fatty acid methyl esters by weight, approximately 25% monoacyl...

example 2

[0057] According to the procedure described below, biodiesel fuel was produced from waste cooking oil discharged from households using the apparatus shown in FIG. 1. A coil form HC-22 reaction tube (inner diameter: 1.8 mm; length: 7.8 m; interior volume: approximately 20 ml) was used.

[0058] First, large impurities such as residues remaining after deep-frying were exclusively removed from waste cooking oil discharged from households without pretreatment, such as dehydration or removal of free fatty acids. A delivery pump was adjusted so that the volume ratio of the waste cooking oil to methanol became 2:1.

[0059] The temperature inside the reaction tube was 380° C., the pressure therein was 40 MPa, the time necessary for passing through the reaction tube was 4 minutes, and the temperature at the time of injection was 270° C. Given the circumstances, the product had a coefficient of viscosity of 24.3 mPa*sec. This value was larger than that of common biodiesel fuel (8.6 mPa*sec). The...

example 3

[0061] According to the procedure described below, biodiesel fuel was produced from commercially available lard using the apparatus shown in FIG. 1. A coil form HC-22 reaction tube (inner diameter: 1.8 mm; length: 7.8 m; interior volume: approximately 20 ml) was used.

[0062] Lard (high-quality lard; fat content: 99.5%; Miyoshi Oil & Fat Co., Ltd.) was placed into a tank 1 for starting materials, and the content of the tank was heated and maintained at 60° C. in order to improve the fluidity. Methanol (reagent chemicals, Wako Pure Chemical Industries, Ltd.) was placed in a tank 2 for starting materials. A delivery pump was adjusted so that the mixing ratio of lard to methanol became 1:2. The temperature in the reaction tube was 500° C., the pressure therein was 40 MPa, the time necessary for passing through the reaction tube was 8 minutes, and the temperature at the time of injection was 300° C. Given the circumstances, the resulting biodiesel fuel was comprised of 56% various fatty ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com