Method for producing epoxy plasticizer using waste grease

A technology of epoxy plasticizer and waste oil, which is applied in the production of plasticizers, and uses waste oil to produce epoxy plasticizers. It can reduce the harm to the environment and people's health, improve flexibility, and have a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

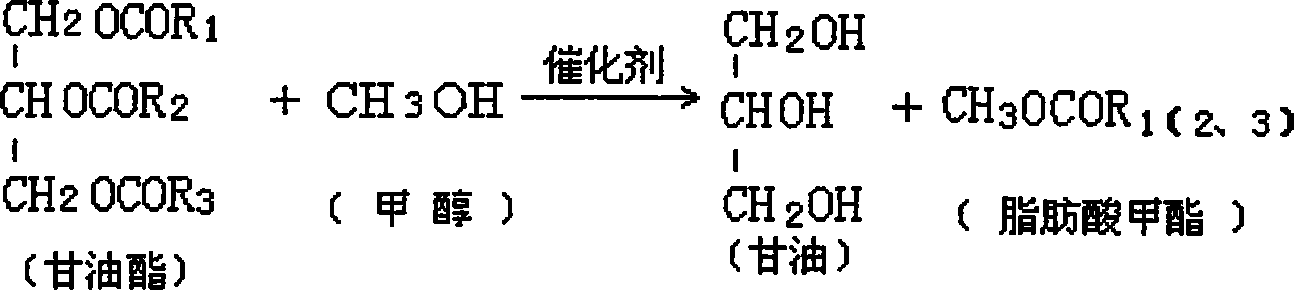

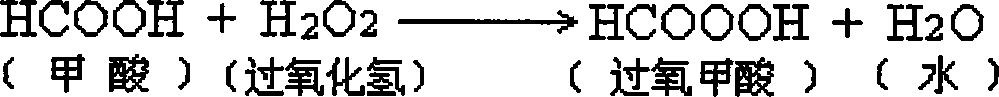

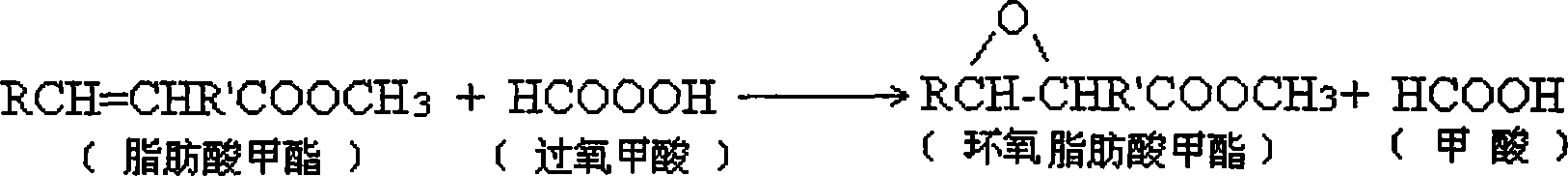

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the waste oil is heated to 45 ℃ and filtered through a filter press to remove solid particles to obtain hot oil, add 3~6% sodium hydroxide solution to the hot oil, fully stir and then extract and separate and remove fatty acid sodium and colloid, take a sample When the acid value (KOHmg / g) is less than 1.0 by analysis and determination, carry out vacuum distillation, dehydration and deodorization, and at -0.05MPa, heat to 80 ° C until the water evaporates and remove the peculiar smell at the same time; then use activated clay for adsorption and decolorization (with Activated clay is 1 part, 30 parts of fats and oils are fed in proportions), and the activated clay is recycled and reused, and the glycerides obtained are pumped into the transesterification kettle, and the weight ratio of glycerides, methanol and sodium hydroxide is: 1: (0.20 ~0.24): (0.00036~0.00044) feed intake, heat and stir, react 2 hours under reflux state; After the reaction finishes, thi...

Embodiment 2

[0027] Embodiment 2: the basic catalyst used in the transesterification process is potassium hydroxide, and other technical parameters and operation steps are the same as those in the embodiment, to obtain the epoxy fatty acid methyl ester finished product.

Embodiment 3

[0028] Example 3: For organic acid, acetic acid was used instead of formic acid, and other technical parameters and operation steps were the same as those in Example 1 to obtain the finished epoxy plasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com