Continuous algal biodiesel production facility

a technology of algal biodiesel and production facilities, which is applied in the direction of biofuels, biofeedstocks, biofuels, etc., can solve the problems of limited long-term supply of oil, limited how much further production is feasible, and ethanol production is only sufficient to meet about 1.5% of u.s. fuel needs, and consumes over 20% of total u.s. corn production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

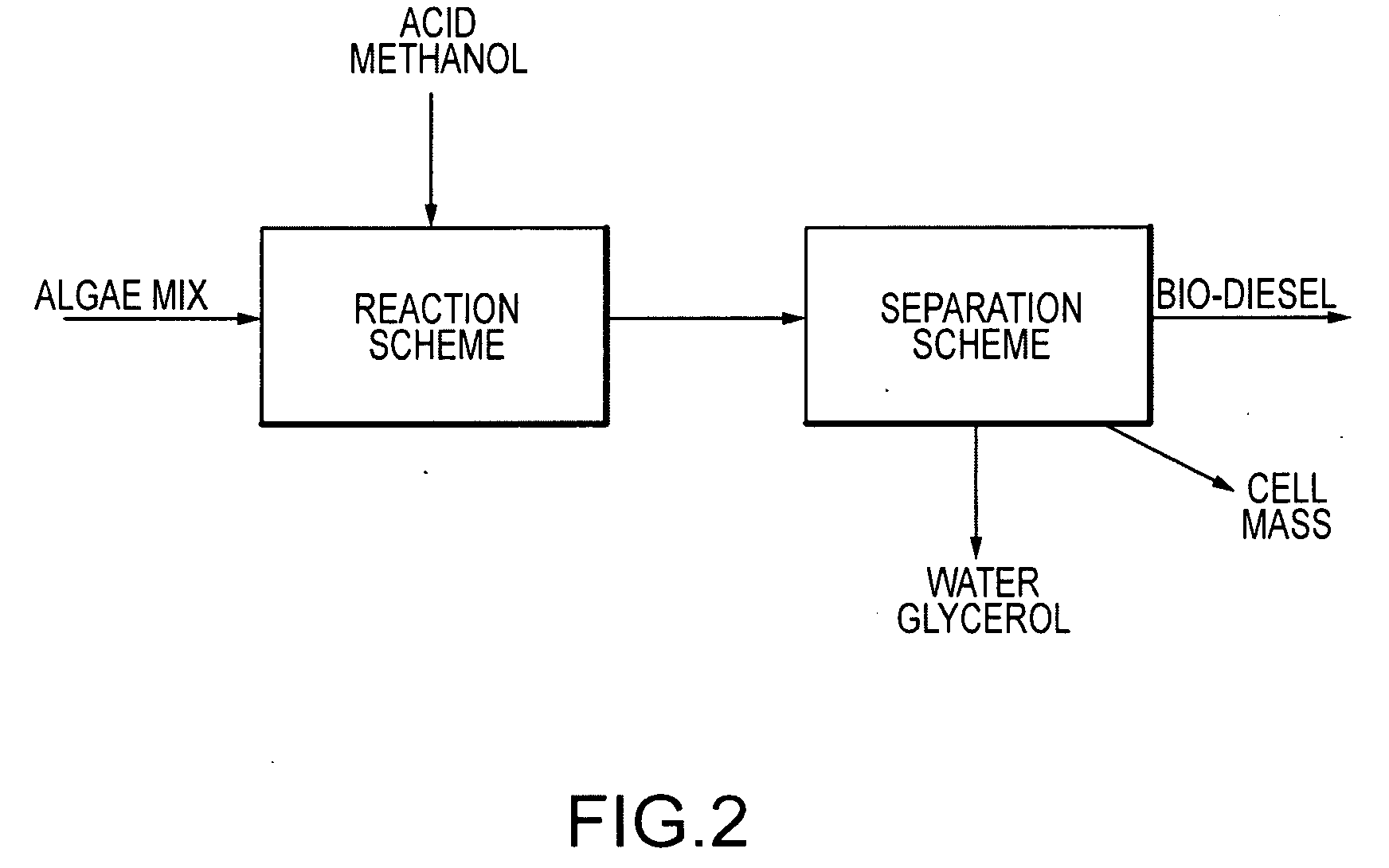

[0050]Biofuel Production from Algal Culture

[0051]Algae are a very diverse and simple group of aquatic plant that are widespread across the world. Algae can vary in form from Eukaryote to Bacteria, and are spread across the kingdoms Plantae, Protista, and Protozoa. All forms contain biomass, which can be converted to various renewable fuels. In some embodiments, the types used for culture are photosynthetic Plantae algae, although the skilled artisan will realize that alternative algal types may be utilized in the practice of the disclosed methods. The algae are selected for their high lipid content and efficient growth under a variety of conditions.

[0052]Algae is a beneficial feed stock because it has the potential to provide over one hundred twenty times the fuel output (per acre) of soybeans, the primary crop used for present biodiesel production. Even palm oil, which has gained popularity recently, has a lower order of magnitude for production per acre. Algae farms are also advan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| fatty acid | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com