Energy filtrated magnetron sputtering plating method and apparatus for applying the method

A magnetron sputtering coating and energy filtering technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc. Strong water-based, damage-inhibiting, little-change effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

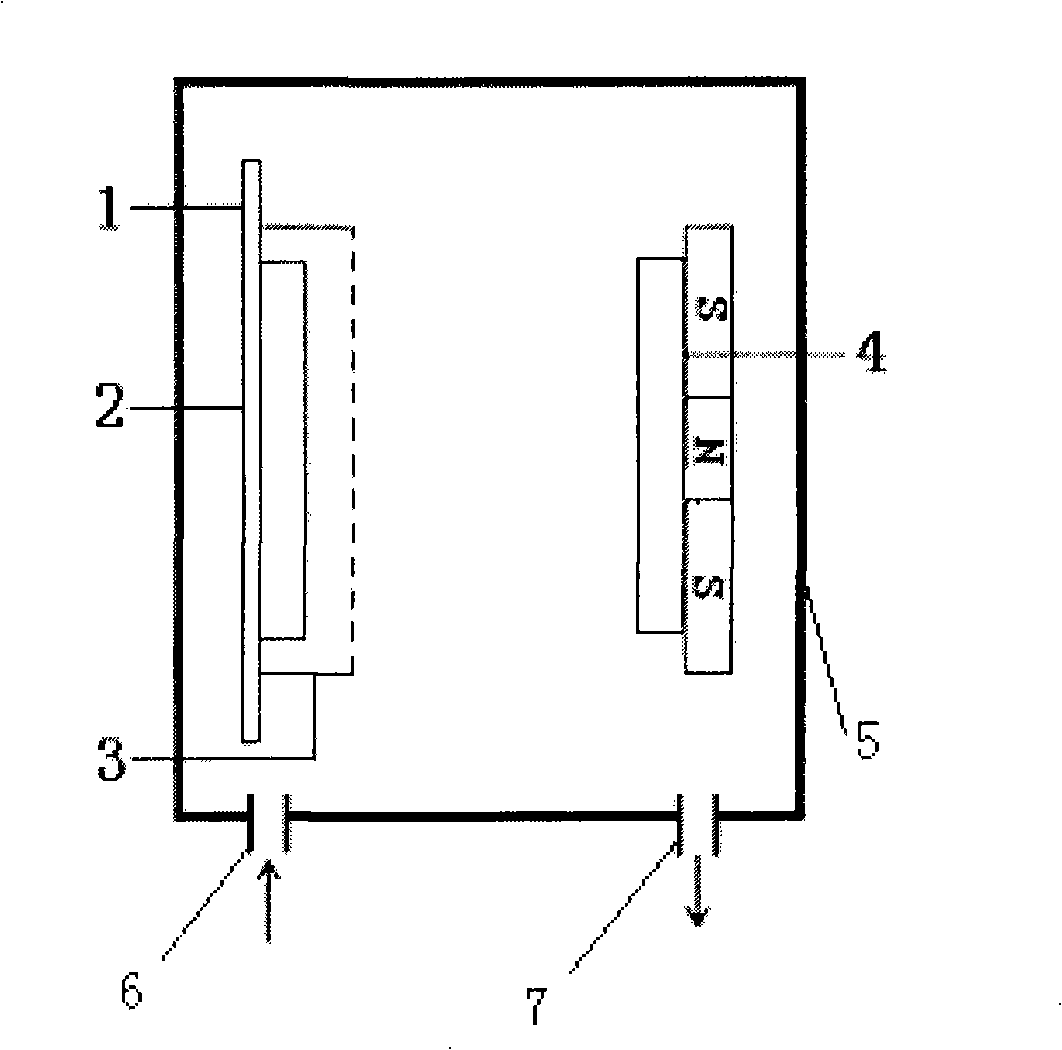

[0026] like figure 1 As shown, the energy-filtering magnetron sputtering coating device of the present invention includes a substrate holder 1 and a sputtering target 4 oppositely arranged in a vacuum chamber 5, the vacuum chamber 5 has inlet and outlet ports 6, 7, and the substrate holder 1 The substrate 2 to be coated is installed on the opposite surface of the sputtering target 4, the sputtering target 4 is a cathode, the substrate support 1 is an anode, and a magnet capable of generating a magnetic field is also arranged behind the sputtering target 4, above The content is all the disclosed technology of the existing magnetron sputtering coating device, and its specific details will not be described in detail here. The innovation of the present invention is that: a conductive filter 3 that can cover the opposite surface of the substrate 2 and the sputtering target 4 is provided between the substrate holder 1 and the sputtering target 4 in the vacuum chamber 5, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com