High-graphite carbon electrode and preparation method thereof

A carbon electrode, high graphite technology, applied in electric heating devices, electrical components, heating by discharge, etc., can solve the problems of high resistivity, high thermal expansion coefficient, low heat treatment temperature of electric calcined coal, etc. Wet corner, the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

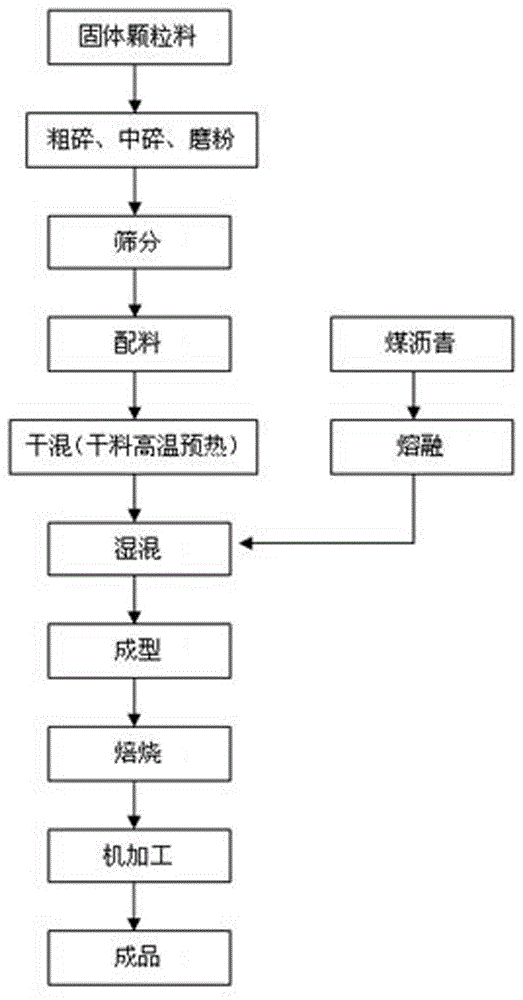

Image

Examples

Embodiment 1

[0030] A method for high graphitic carbon electrodes, comprising the steps of:

[0031] (1) Crushing, sieving, and grinding: respectively crushing and sieving graphite crushed and graphitized anthracite to obtain granular materials, wherein the particle size of graphitized anthracite is 1-4mm and 4-10mm, and the particle size of graphite crushed is 10mm ~16mm and 16mm~30mm; grind the graphitized petroleum coke to obtain a powder with a particle size of less than 1mm, and the purity of the particles less than 0.075mm is not less than 50%;

[0032] (2) Ingredients: 30 parts by weight of graphitized petroleum coke, 30 parts by weight of graphitized anthracite and 40 parts by weight of crushed graphite; the amount of powder less than 1mm accounts for 40% of the total mass of the solid mixture, and the amount of powder below 0.075mm accounts for 40% of the total mass of the solid mixture. 20% of the total mass of the mixture; 1-4mm, 4-10mm, and 10-16mm three particle sizes account ...

Embodiment 2

[0039] (1) Crushing, sieving, and grinding: respectively crushing and sieving graphite crushed and graphitized anthracite to obtain granular materials, wherein the particle size of graphitized anthracite is 1-4mm and 4-10mm, and the particle size of graphite crushed is 10mm ~16mm and 16mm~30mm; grind the graphitized petroleum coke to obtain a powder with a particle size of less than 1mm, and the purity of the particles less than 0.075mm is not less than 50%;

[0040] (2) Ingredients: 50 parts by weight of graphitized petroleum coke, 30 parts by weight of graphitized anthracite and 20 parts by weight of crushed graphite; the amount of powder less than 1mm accounts for 50% of the total mass of the solid mixture, and the amount of powder below 0.075mm accounts for 50% of the total mass of the solid mixture. 40% of the total mass of the mixture; 1-4mm, 4-10mm, and 10-16mm three particle sizes account for 30% of the total mass of the solid mixture, and 16mm-30mm large particles acco...

Embodiment 3

[0047] (1) Crushing, sieving, and grinding: respectively crushing and sieving graphite crushed and graphitized anthracite to obtain granular materials, wherein the particle size of graphitized anthracite is 1-4mm and 4-10mm, and the particle size of graphite crushed is 10mm ~16mm and 16mm~30mm; grind the graphitized petroleum coke to obtain a powder with a particle size of less than 1mm, and the purity of the particles less than 0.075mm is not less than 50%;

[0048] (2) Ingredients: 30 parts by weight of graphitized petroleum coke, 50 parts by weight of graphitized anthracite and 20 parts by weight of crushed graphite; the amount of powder less than 1mm accounts for 40% of the total mass of the solid mixture, and the amount of powder below 0.075mm accounts for 40% of the total mass of the solid mixture. 30% of the total mass of the mixture; 1-4mm, 4-10mm, and 10-16mm three particle sizes account for 55% of the total mass of the solid mixture, and 16mm-30mm large particles acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com