Preparation method of disc type full silicon carbide filtering membrane

A technology of full silicon carbide and filter membrane, applied in ceramic products, applications, household appliances, etc., to achieve the effect of large separation flux, strong hydrophilicity and oil repellency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of disc-type full silicon carbide filter membrane support

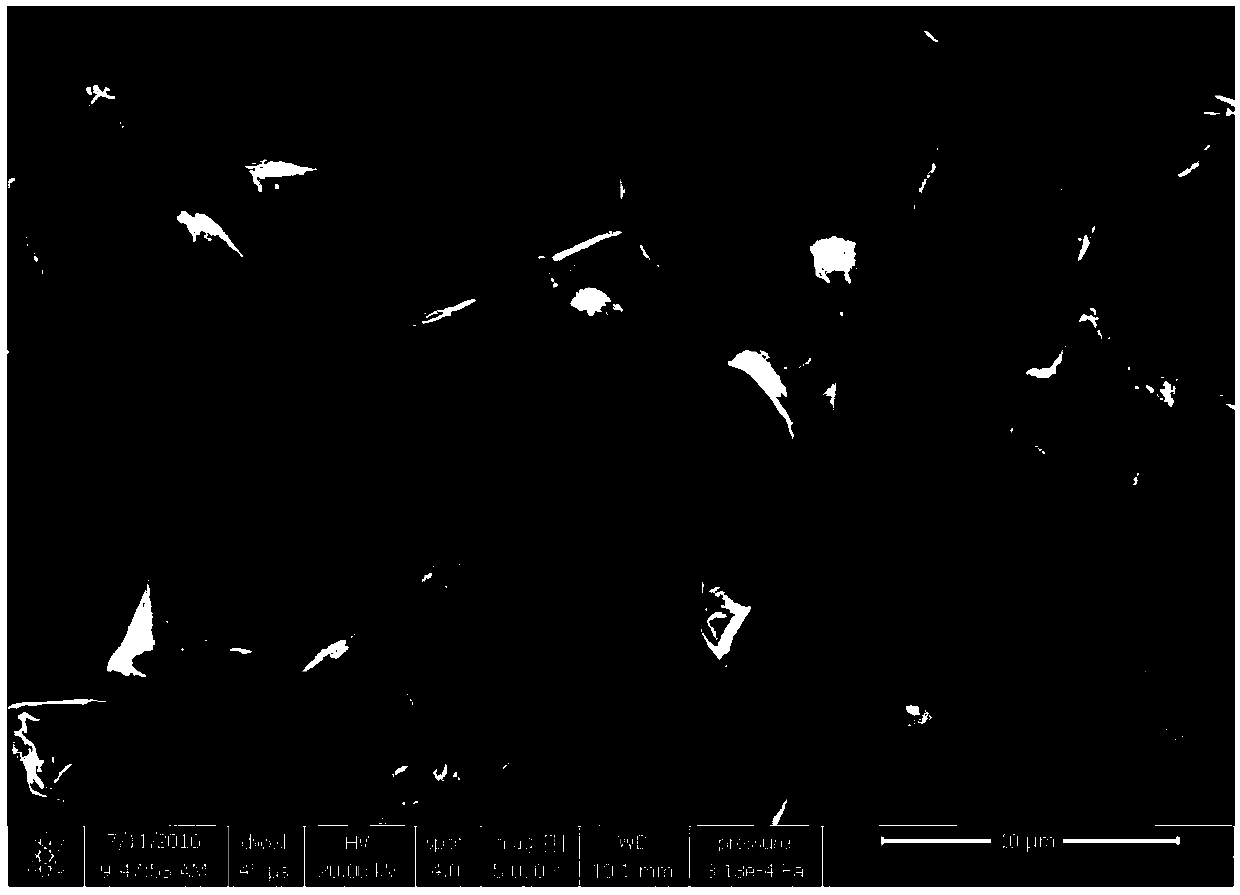

[0039] Weigh 100 parts of silicon carbide coarse powder I with an average particle size of 40 μm, 7 parts of silicon carbide fine powder II with an average particle size of 3 μm and a purity greater than 98%, and 4 parts of sodium carboxymethylcellulose with a molecular weight of 13,000 and a purity greater than 98%. , 12 parts of carbon black with an average particle size of 0.1-10 μm, stir and dissolve sodium carboxymethyl cellulose in warm water at 40°C, then add coarse silicon carbide powder Ⅰ, fine silicon carbide powder Ⅱ and carbon black in sequence, and use high-speed The mixer is mixed evenly; among them, the SEM image of silicon carbide fine powder II is as follows figure 2 As shown, the average particle size of the particles is about 3 μm, and the particle size is relatively consistent;

[0040] The uniformly mixed mud is dried and sieved, then put into the forming mold, and dry-pres...

Embodiment 2

[0048] 1) Preparation of disc-type full silicon carbide filter membrane support

[0049] Weigh 100 parts of silicon carbide coarse powder I with an average particle size of 45 μm, 6 parts of silicon carbide fine powder II with an average particle size of 2 μm and a purity greater than 98%, and 3 parts of sodium carboxymethylcellulose with a molecular weight of 15,000 and a purity greater than 98% , 14 parts of carbon black with an average particle size of 0.1-10 μm, stir and dissolve sodium carboxymethyl cellulose in warm water at 40°C, then add coarse silicon carbide powder Ⅰ, fine silicon carbide powder Ⅱ and carbon black in sequence, and mix with high speed The feeder mixes evenly;

[0050] The evenly mixed mud material is dried and sieved, then loaded into the forming mold, and then dry-pressed on a large-tonnage press to obtain a biscuit. The pressure of the dry-press forming is bidirectional pressure, and the pressure is 8MPa;

[0051] Use silicon carbide fine powder II...

Embodiment 3

[0058] 1) Preparation of disc-type full silicon carbide filter membrane support

[0059] Weigh 100 parts of silicon carbide coarse powder I with an average particle size of 30 μm, 9 parts of silicon carbide fine powder II with an average particle size of 1 μm and a purity greater than 98%, and 4 parts of sodium carboxymethylcellulose with a molecular weight of 12,000 and a purity greater than 98%. , 11 parts of carbon black with an average particle size of 0.1-10 μm, stir and dissolve sodium carboxymethyl cellulose in warm water at 40°C, then add coarse silicon carbide powder Ⅰ, fine silicon carbide powder Ⅱ and carbon black in sequence, and mix with high speed The feeder mixes evenly;

[0060] The uniformly mixed mud is dried and sieved, then put into the forming mold, and dry-pressed on a large-tonnage press to obtain a green body. The pressure of the dry-press forming is bidirectional pressure, and the pressure is 12MPa;

[0061] Use silicon carbide fine powder II, polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com