Multifunctional carbon molecular sieve derived from metal organic framework material/self-polymerized microporous polymer composite, and preparation method and application thereof

A metal-organic framework and microporous polymer technology, applied in alkali metal compounds, alkali metal oxides/hydroxides, separation methods, etc., can solve problems such as difficult to achieve high-efficiency separation, achieve good industrial application prospects, and high-efficiency separation , the effect of strong thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

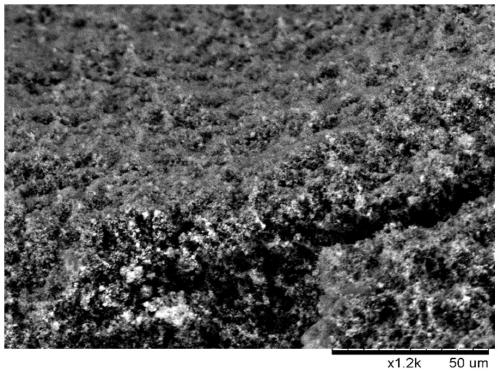

[0041] Example 1 metal-organic framework material CuBTC / self-porous polymer PIM-1 composite derived carbon molecular sieve

[0042] (1) Preparation of metal-organic framework material CuBTC:

[0043] First, 1.4496g Cu(NO 3 ) 2 ·3H 2O. 0.6303g of trimesic acid was completely dissolved in 100mL of N,N-dimethylformamide solution, stirred and mixed evenly at room temperature, then the mixture was placed in a hydrothermal reactor, and reacted at 100°C for 15h. The product obtained after the reaction was centrifuged and washed several times with ethanol until the supernatant was colorless. The blue gel-like product was vacuum-dried at 60°C to obtain a solid metal-organic framework CuBTC.

[0044] (2) Preparation of self-porous polymer PIM-1:

[0045] First, 34.0 g of 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-helical bisindane (TTSBI), 20.0 g of tetrafluoropara Diphthalonitrile (DCTB), 40.0g K 2 CO 3 The mixture was placed in 200mL DMAc and 100mL toluene solution, he...

Embodiment 2

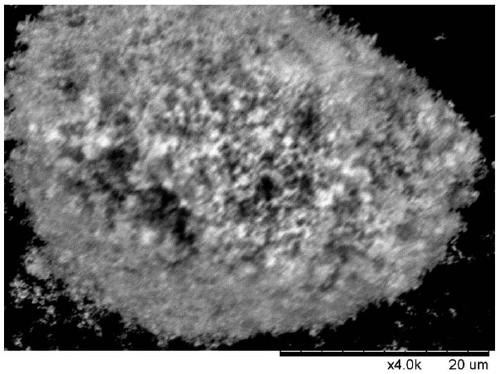

[0051] Example 2 Metal-organic framework material CuBDC / self-porous polymer PIM-1 composite derived carbon molecular sieve

[0052] (1) Preparation of metal-organic framework material CuBDC:

[0053] First, 1.6534g Cu(NO 3 ) 2 ·3H 2 O. 0.9969g of terephthalic acid was completely dissolved in 100mL of N,N-dimethylformamide solution, stirred and mixed evenly at room temperature, then the mixture was placed in a hydrothermal reactor, and reacted at 80°C for 20h. The product obtained after the reaction was centrifuged and washed several times with ethanol until the supernatant was colorless. The blue gel-like product was vacuum-dried at 60° C. to obtain a solid metal-organic framework CuBDC.

[0054] (2) Preparation of self-porous polymer PIM-1:

[0055] First, 34.0 g of 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'-helical bisindane (TTSBI), 20.0 g of tetrafluoropara Diphthalonitrile (DCTB), 40.0g K 2 CO 3 The mixture was placed in 200mL DMAc and 100mL toluene soluti...

Embodiment 3

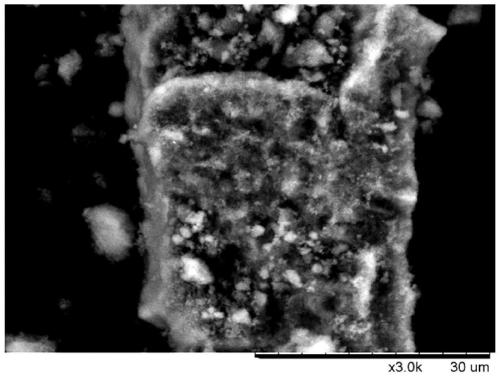

[0072] Embodiment 3 gas adsorption separation performance test

[0073] The porous framework materials prepared in the above-mentioned Examples 1, 2 and Comparative Examples 1, 2 were tested for their performance against CO 2 and N 2 selectivity of adsorption separation. The performance of the synthesized porous adsorbent material was evaluated by calculating and analyzing the adsorption capacity of single-component gas.

[0074] Experimental procedure for adsorption separation of porous materials: the synthesized porous framework material was placed in a vacuum oven, and stood at 120° C. for 12 hours under vacuum conditions. The pretreated sample is sealed in the sample chamber of the device, and the device is evacuated to make the whole system in a vacuum state. After the whole system is stable, the gas to be tested is introduced. In a single-component gas system (such as CO 2 and N 2 ) in the adsorption separation test, the pressure gauge is used to measure the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com