High-activity modified metakaolin-based mineral admixture for concrete and preparation method for mineral admixture

A technology of mineral admixture and metakaolin, which is applied in the field of highly active modified metakaolin-based concrete mineral admixture and its preparation, can solve the problems of reduced concrete work performance, mutual interference of water reducing agents, and influence on normal construction, etc., to achieve Improve work performance, increase secondary hydration, and improve post-durability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

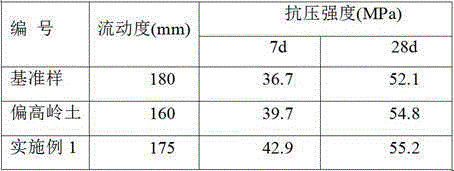

Embodiment 1

[0022] A highly active modified metakaolin-based concrete mineral admixture, which firstly makes metakaolin by grinding kaolin and calcining at a temperature of 850°C for 2 hours and then cooling to obtain metakaolin, wherein the SiO in metakaolin is guaranteed 2 with Al 2 o 3 The sum of the mass percentages is ≥50wt%, and the specific surface area is ≥2300m 2 / kg, then metakaolin was placed in a 100°C oven for 24h, and finally metakaolin and modifier were ground in a ball mill for 30min to obtain modified metakaolin, wherein the mass ratio of metakaolin to modifier was 50:1, The modifying agent is prepared by mixing stearic acid, calcium stearate and methyl silicone oil in order of 80%, 10% and 10% by mass.

[0023] Taking the mortar specimen as the object of investigation, metakaolin and modified metakaolin were used to replace the cementitious material with 5% equivalent to configure the mortar. Select standard sand with a water-cement ratio of 0.45. According to GB / T 2...

Embodiment 2

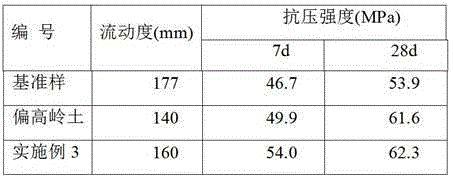

[0029] A highly active modified metakaolin-based concrete mineral admixture, which firstly makes metakaolin by grinding kaolin and calcining at a temperature of 850°C for 2 hours and then cooling to obtain metakaolin, wherein the SiO in metakaolin is guaranteed 2 with Al 2 o 3 The sum of the mass percentages is ≥50wt%, and the specific surface area is ≥2300m 2 / kg, then metakaolin was placed in a 100°C oven for 24h, and finally metakaolin and modifier were ground in a ball mill for 30min to obtain modified metakaolin, wherein the mass ratio of metakaolin to modifier was 100:1, The modifying agent is prepared by mixing stearic acid, calcium stearate and methyl silicone oil in order of 80%, 10% and 10% by mass.

[0030] Taking the mortar specimen as the object of investigation, metakaolin and modified metakaolin were used to replace the cementitious material with 5% equivalent to configure the mortar. Select standard sand with a water-cement ratio of 0.45. According to GB / T 2...

Embodiment 3

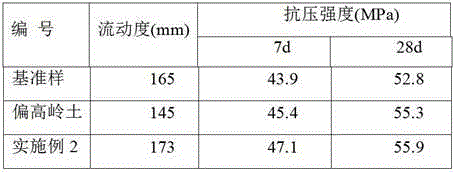

[0036] A highly active modified metakaolin-based concrete mineral admixture, which firstly makes metakaolin by grinding kaolin and calcining at a temperature of 650°C for 6 hours and then cooling to obtain metakaolin, wherein the SiO in metakaolin is guaranteed 2 with Al 2 o 3 The sum of the mass percentages is ≥50wt%, and the specific surface area is ≥2300m 2 / kg, then metakaolin was placed in a 100°C oven for 24h, and finally metakaolin and modifier were ground in a ball mill for 60min to obtain modified metakaolin, wherein the mass ratio of metakaolin to modifier was 50:1, The modifying agent is prepared by mixing stearic acid, calcium stearate and methyl silicone oil in order of 50%, 25% and 25% by mass.

[0037] Taking the mortar specimen as the investigation object, metakaolin and modified metakaolin were used to replace the cementitious material with 10% equal amount to configure the mortar. Select standard sand with a water-cement ratio of 0.45. According to GB / T 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com