Easy-to-clean antiskid wear-resistant floor coating as well as preparation and use method thereof

A ground coating and easy-to-clean technology, applied in fire-retardant coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of decreased anti-fouling performance, difficult cleaning of coatings, and easy formation of dead corners, etc. The effect of improving roughness and friction coefficient, improving mechanical strength, and increasing anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An easy-to-clean anti-slip and wear-resistant floor coating, comprising 100 parts of coating components and 45 parts of curing agent components in parts by mass;

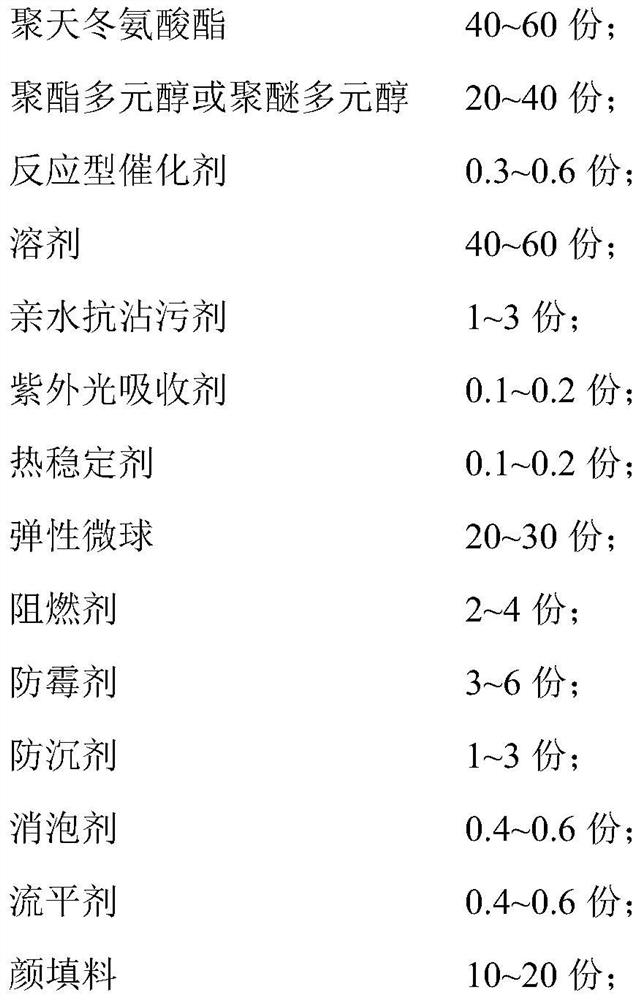

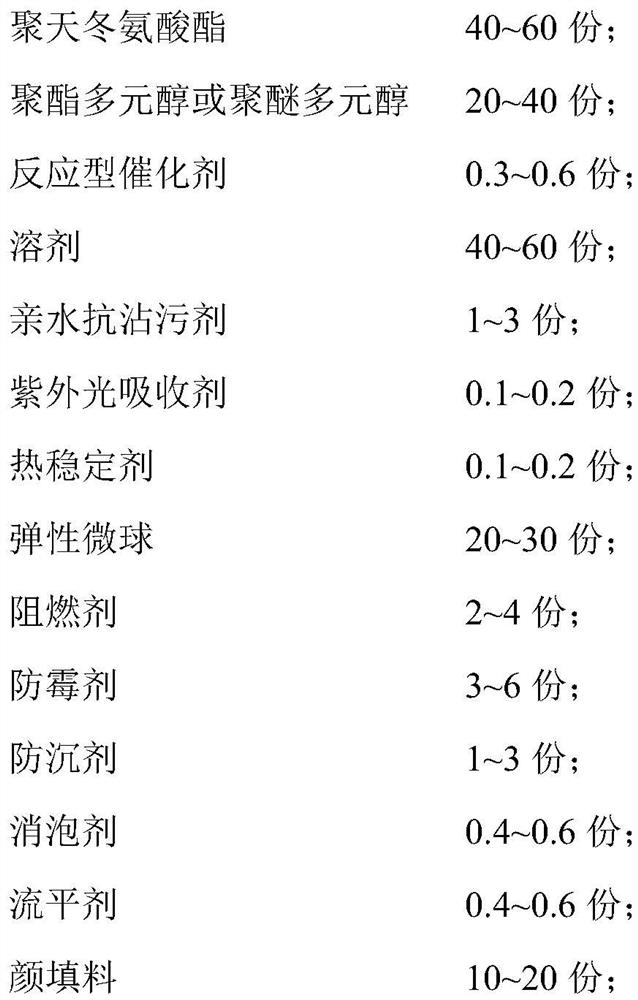

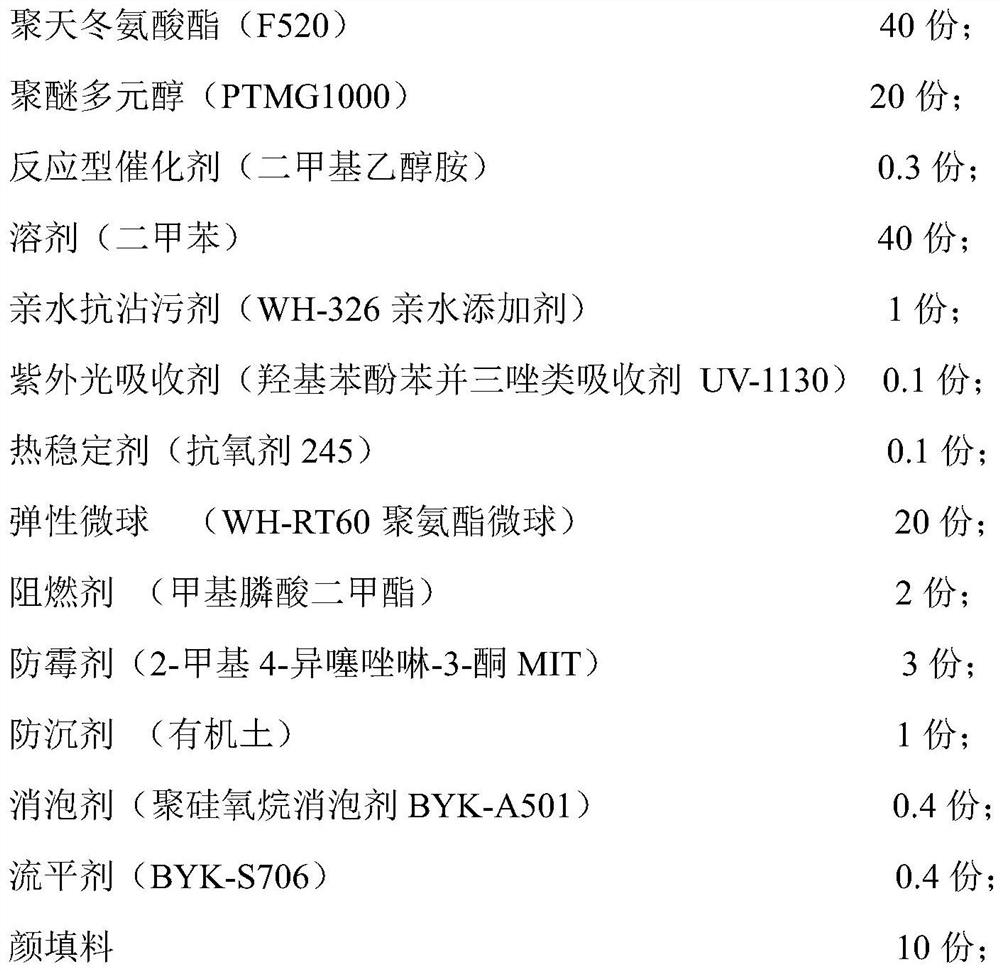

[0037] Described coating component comprises the raw material of following mass parts:

[0038]

[0039] Described curing agent component comprises the raw material of following mass parts:

[0040] Diisocyanate (IPDI) 100 parts

[0041] Dihydric alcohol (PTMG1000) 120 parts

[0042] Polyisocyanate (HDI trimer) 6.6 parts

[0043] The preparation method of the easy-to-clean anti-slip wear-resistant floor coating is as follows:

[0044] (B1) 40 parts of polyaspartic ester, 20 parts of polyether polyol, 0.3 part of reaction catalyst, 40 parts of solvent, 1 part of hydrophilic anti-fouling agent, 0.1 part of ultraviolet light absorber, 0.1 part of heat stabilizer agent, 2 parts of flame retardant, 3 parts of antifungal agent, 1 part of anti-settling agent, 0.4 part of defoamer, 0.4 part of leveling agent, ...

Embodiment 2

[0050] An easy-to-clean anti-slip and wear-resistant floor coating, comprising 100 parts of coating components and 70 parts of curing agent components in parts by mass;

[0051] Described coating component comprises the raw material of following mass parts:

[0052]

[0053] Described curing agent component comprises the raw material of following mass parts:

[0054] Diisocyanate (HMDI) 100 parts

[0055] Dihydric alcohol (PTMG1000) 180 parts

[0056] Polyisocyanate (IPDI trimer) 16.8 parts

[0057] The preparation method of the easy-to-clean anti-slip wear-resistant floor coating is as follows:

[0058] (B1) 60 parts of polyaspartic ester, 40 parts of polyester polyol, 0.6 part of reaction catalyst, 60 parts of solvent, 3 parts of hydrophilic anti-fouling agent, 0.2 part of ultraviolet light absorber, 0.2 part of thermal stabilizer agent, 4 parts of flame retardant, 6 parts of antifungal agent, 3 parts of anti-settling agent, 0.6 part of defoamer, 0.6 part of leveling ...

Embodiment 3

[0064] An easy-to-clean anti-slip and wear-resistant floor coating, comprising 100 parts of coating components and 70 parts of curing agent components in parts by mass;

[0065] Described coating component comprises the raw material of following mass parts:

[0066]

[0067]

[0068] Described curing agent component comprises the raw material of following mass parts:

[0069] Diisocyanate (IPDI) 100 parts

[0070] Dihydric alcohol (PTMG1000) 150 parts

[0071] Polyisocyanate (HDI trimer) 12.5 parts

[0072] The preparation method of the easy-to-clean anti-slip wear-resistant floor coating is as follows:

[0073] (B1) Mix 50 parts of polyaspartic acid ester, 30 parts of polyether polyol, 0.5 part of reactive catalyst, 50 parts of solvent, 2 parts of hydrophilic anti-fouling agent, 0.15 part of ultraviolet light absorber, 0.15 part of thermal stabilizer agent, 3 parts of flame retardant, 5 parts of antifungal agent, 2 parts of anti-settling agent, 0.5 part of defoamer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com