Graphene nanoparticle composite material and preparation method thereof

A technology of nano-particles and composite materials, applied in the field of composite materials, can solve the problems of graphene oxide not being utilized, and achieve the effects of easy regulation, mild reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

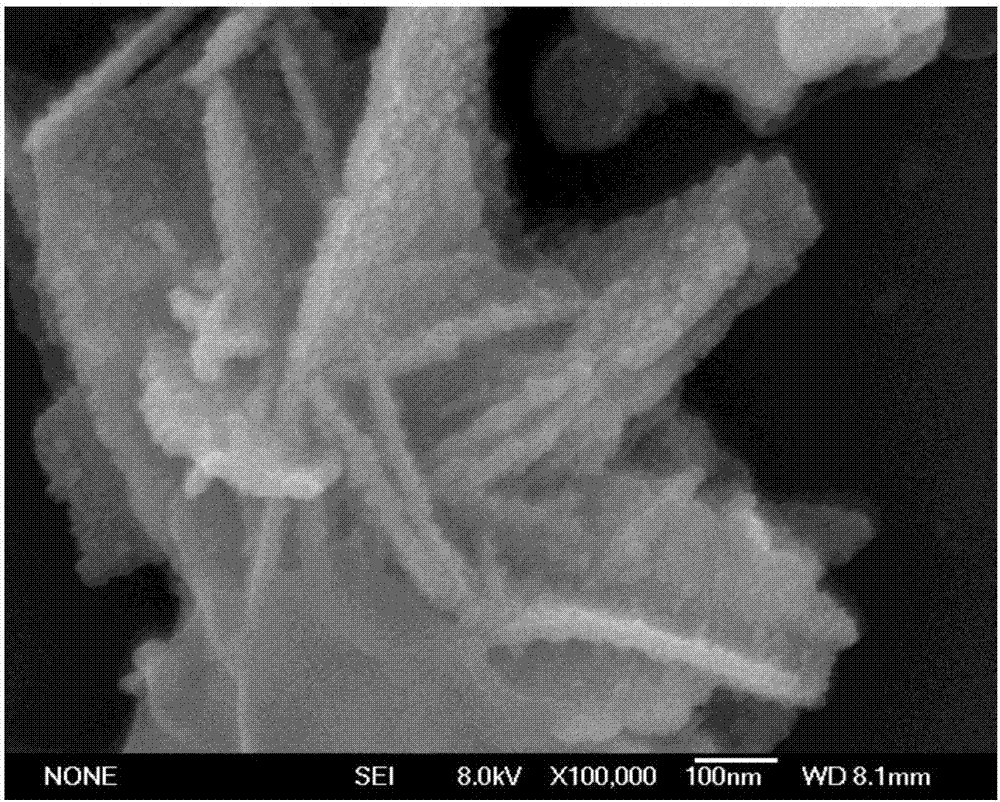

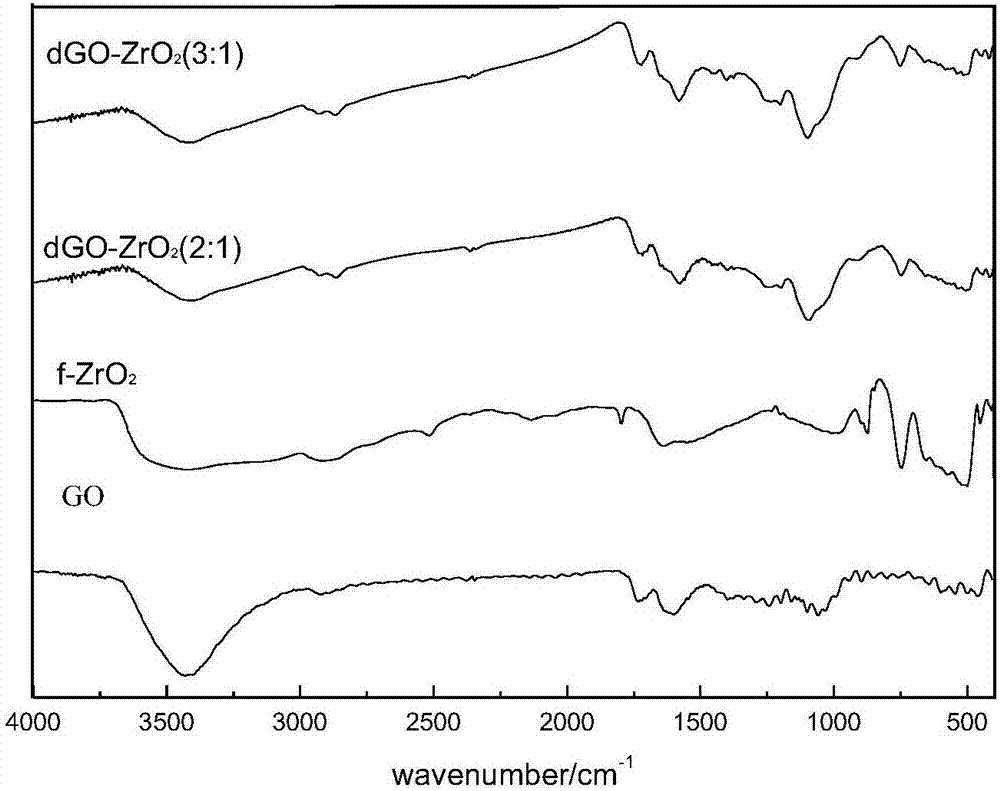

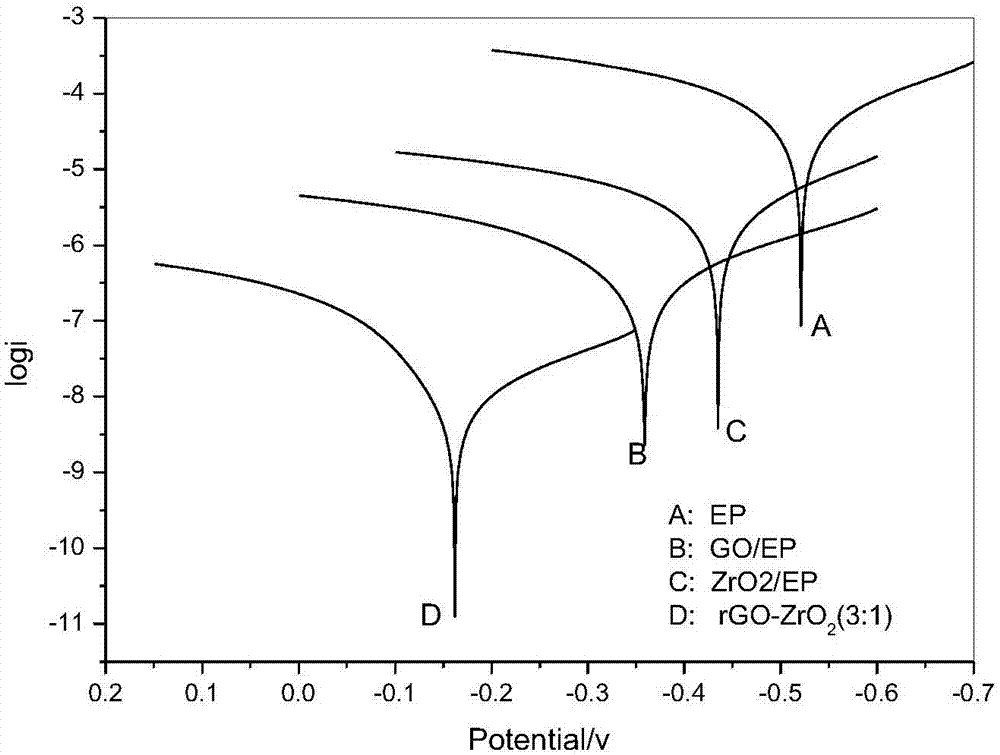

[0031] (1) Using natural flake graphite as raw material, graphene oxide was prepared by the improved Hummers method. Weigh 1.0g of flake graphite, 3g of potassium permanganate, and 0.5g of sodium nitrate into the cooled kettle in turn, then add 30mL of 98% concentrated sulfuric acid, quickly cover and tighten the lid of the kettle, put it in the refrigerator for 30min at low temperature; take out the reaction Put it in an oven at 80°C for 10 minutes, take it out and cool it to room temperature; pour the product into a beaker filled with 100ml deionized water, add a certain amount of hydrogen peroxide dropwise until the liquid turns bright yellow or earthy yellow; let it stand for 24 hours , Pour off the supernatant, first pickle with 5% HCl for 3 times, and then wash it with water for several times until the pH is 5-7; after centrifuging the obtained solution, the substance at the bottom is high-concentration graphite oxide ene, and graphene oxide was obtained after freeze-dry...

Embodiment 2

[0037] (1) the preparation method of graphene oxide is with the step (1) in the embodiment one;

[0038] (2) Disperse 60 mg of nano-titanium oxide into 90 mL of ethanol solution of γ-aminopropyltriethoxysilane with a volume fraction of 2%, sonicate for 2 hours, add 12 mL of deionized water dropwise in a water bath at 90° C., and react for 10 hours to obtain The product was washed three times with absolute ethanol and deionized water, and freeze-dried to obtain functionalized titanium oxide;

[0039] (3) Disperse 30 mg of graphene oxide into 50 mL of ethanol solution of γ-glycidylpropylmethyldimethoxysilane with a volume fraction of 2%, ultrasonicate for 2 hours, add 6 mL of deionized water dropwise in a water bath at 90°C, After reacting for 10 hours, the obtained product was washed three times with absolute ethanol and deionized water, and freeze-dried to obtain functionalized graphene oxide;

[0040](4) Add 30 mg of functionalized graphene oxide to 5.5 mL of N,N-dimethylfor...

Embodiment 3

[0043] (1) the preparation method of graphene oxide is with the step (1) in the embodiment one;

[0044] (2) Disperse 40 mg of nano-silica into 50 mL of an ethanol solution of γ-aminopropyltriethoxysilane with a volume fraction of 2%, sonicate for 2 hours, add 6 mL of deionized water dropwise in a water bath at 90° C., and react for 10 hours. The obtained product was washed three times with absolute ethanol and deionized water, and freeze-dried to obtain functionalized zirconia;

[0045] (3) Disperse 40 mg of graphene oxide into 40 mL of ethanol solution of γ-glycidylpropylmethyldimethoxysilane with a volume fraction of 2%, ultrasonicate for 2 hours, add 6 mL of deionized water dropwise in a water bath at 90°C, After reacting for 10 hours, the obtained product was washed three times with absolute ethanol and deionized water, and freeze-dried to obtain functionalized graphene oxide;

[0046] (4) Add 30 mg of functionalized graphene oxide to 6 mL of N,N-dimethylformamide, sonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com