Method for preparing grapheme-Ag nano-particle composite material

A nanoparticle and composite material technology, applied in the field of nanomaterial manufacturing, can solve problems such as complex preparation methods, increased product costs, and complex preparation processes, and achieve the effects of simple methods, reduced environmental hazards, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 0.1 g graphene oxide and 1 g AgNO 3 Dissolve in 50ml of water, then sonicate for 30 minutes to mix well;

[0024] Graphene oxide is separated by centrifugation and washed with deionized water several times;

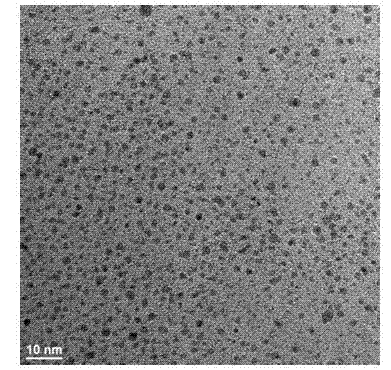

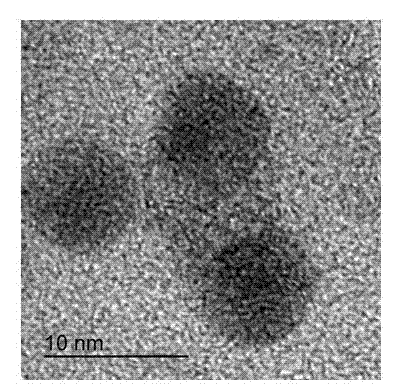

[0025] The graphene oxide obtained in the previous step is heated to 200 degrees Celsius for 10 minutes under vacuum to obtain the graphene-Ag nanoparticle composite material. The morphology of the obtained composite material is as follows figure 1 and figure 2 As shown, the Ag nanoparticles are less than 10 nm in diameter.

Embodiment 2

[0027] Get 0.1 gram of graphene oxide and 0.5 gram of silver perchlorate and dissolve in 100ml of ethanol, then stir for 60 minutes until uniformly mixed;

[0028] Graphene oxide is separated by filtration and washed with ethanol several times;

[0029] The graphene oxide obtained in the previous step was heated to 100 degrees Celsius for 5 hours under nitrogen to obtain the graphene-Ag nanoparticle composite material.

Embodiment 3

[0031] Dissolve 0.5 gram of graphene oxide and 0.1 gram of silver fluoride in 200ml of N-methylpyrrolidone, then stir for 30 minutes until uniformly mixed;

[0032] Graphene oxide is separated by centrifugation and washed with N-methylpyrrolidone several times;

[0033] The graphene oxide obtained in the previous step is heated to 800 degrees Celsius for 5 seconds under a hydrogen atmosphere to obtain a graphene-Ag nanoparticle composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com