Manufacturing method of bamboo pulp household paper and household paper

A technology of household paper and bamboo pulp, which is applied in special paper, thin paper/absorbent paper, paper, etc. It can solve the problems of small wall thickness cavity, stiff paper, spots, etc., to improve the forming performance, improve the paper performance, evenly mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the examples.

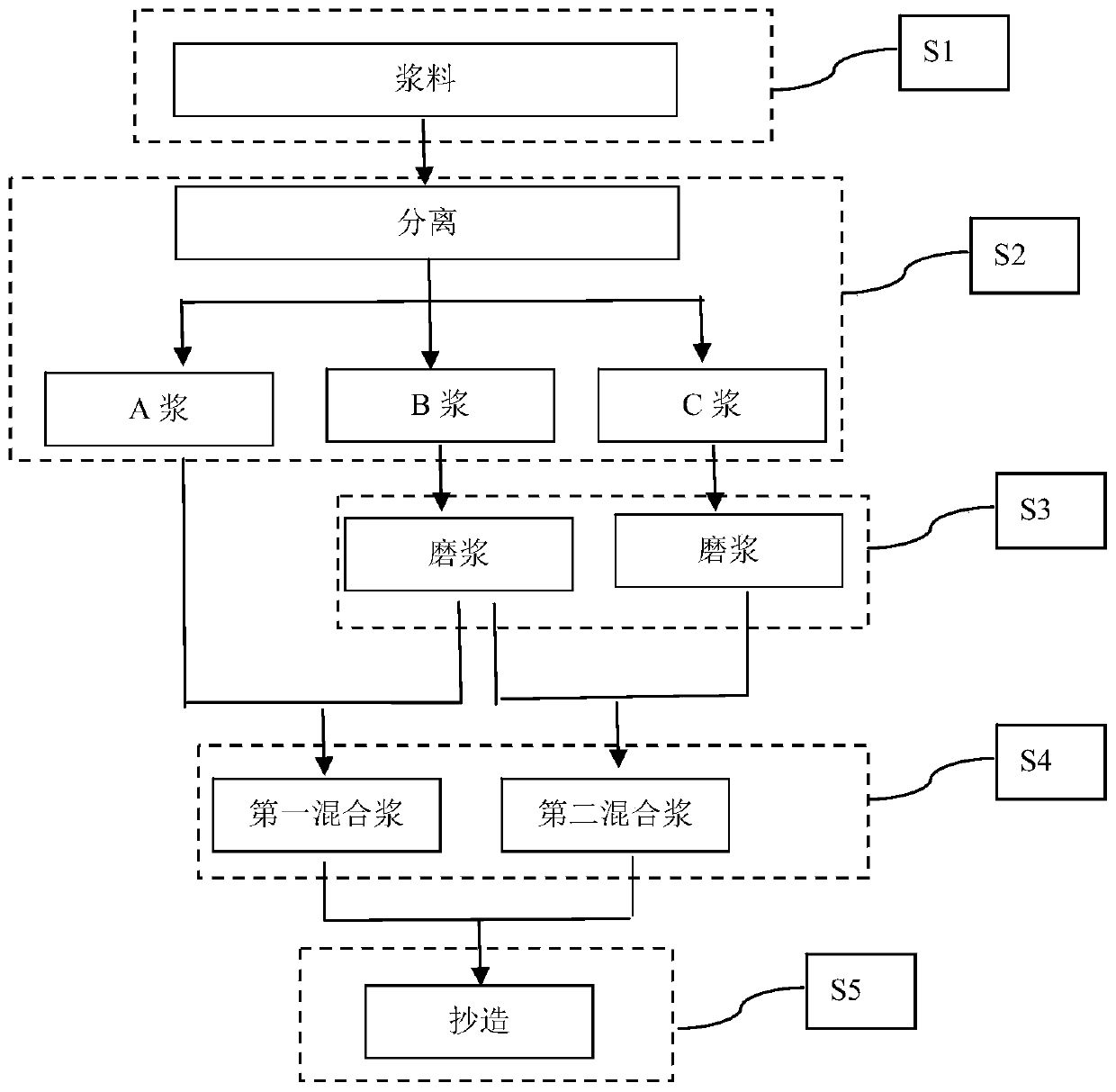

[0024] Please refer to figure 1 , figure 1 Show the flow chart of bamboo pulp household paper making method of the present invention:

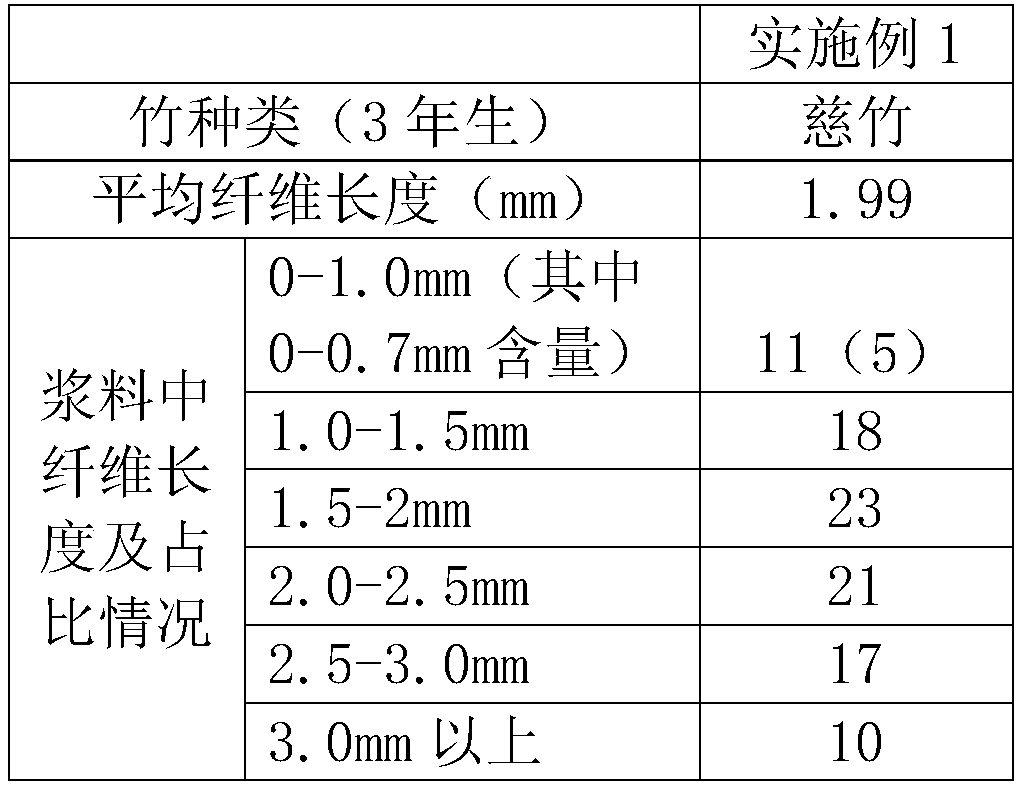

[0025] S1: Provide slurry, wherein the content of bamboo pulp in the slurry is greater than or equal to 85%;

[0026] The bamboo pulp is usually made of bamboo such as Moso bamboo, Phoebe bamboo, Ci bamboo, and large wood bamboo as raw materials, and is a fiber raw material obtained by the sulfate method or caustic soda method. At the same time, the bamboo pulp can be natural color bamboo pulp or bleached bamboo pulp. Bamboo pulp.

[0027] Preferably, in order to utilize bamboo fiber as much as possible, the content of bamboo pulp in the slurry is greater than or equal to 85%. When the content of bamboo pulp in the slurry is not 100%, the pulp of other plant fibers can also be added in the slurry. Material, such as wood pulp, straw pulp or su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com