Method for optimizing paper structure to improve performance of finished paper

A technology for structure improvement and paper making, applied in pulp beating method, pulp beating/refining method, paper making, etc., to improve paper performance and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

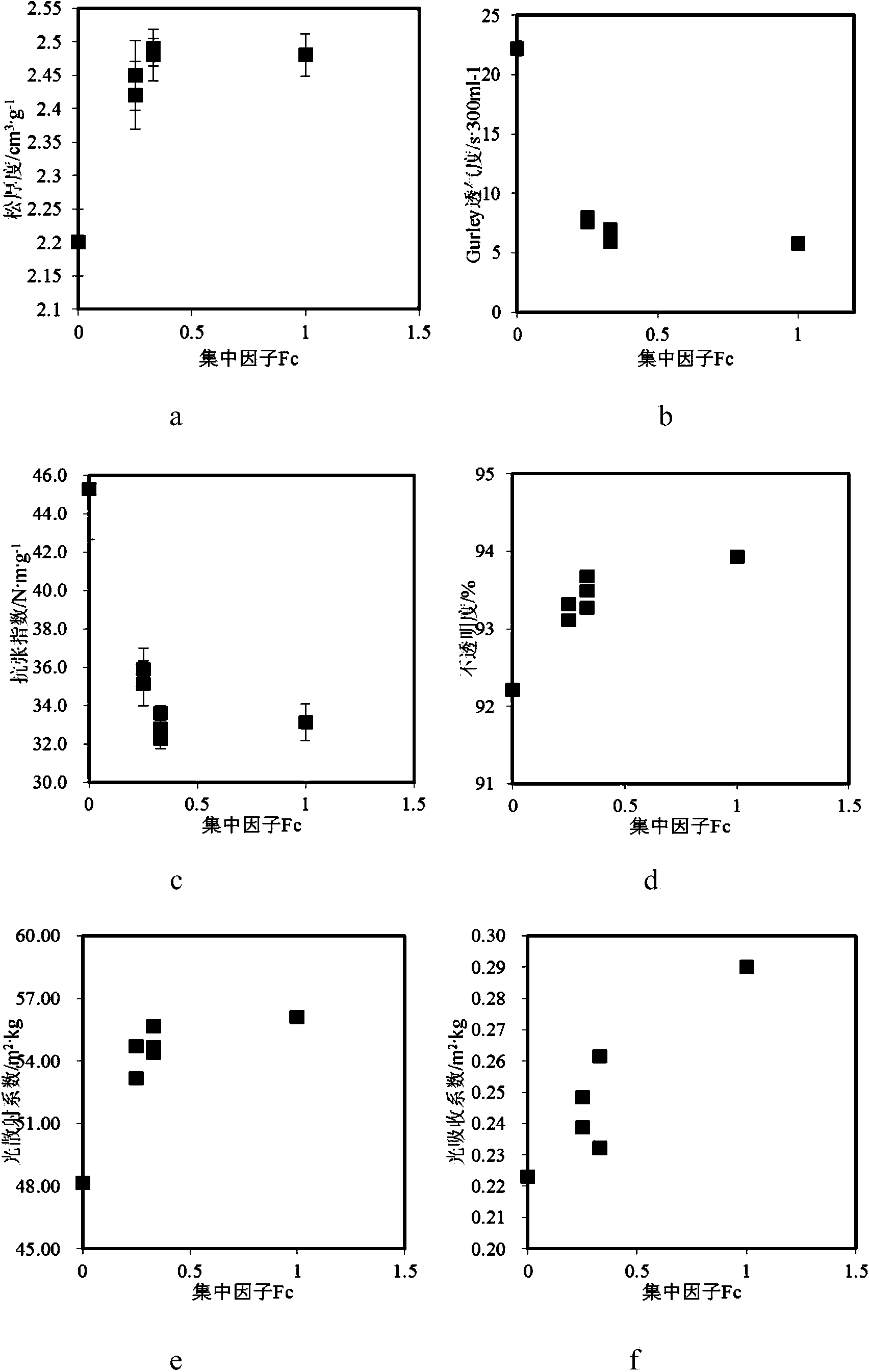

Image

Examples

Embodiment 1

[0031] The paper-forming filler content of present embodiment is 25%, comprises the following steps:

[0032] 1) Disintegration of pulp: fully disintegrate and dehydrate the chemical hardwood pulp to make a slurry with a final concentration of 10%;

[0033] 2) Refining: refining the prepared slurry, the refining concentration is 9%, and the final beating degree of the slurry after refining is 30°SR;

[0034] 3) Preparation of filler suspension: prepare calcium silicate filler suspension with a concentration of 10%, and fully stir and disperse;

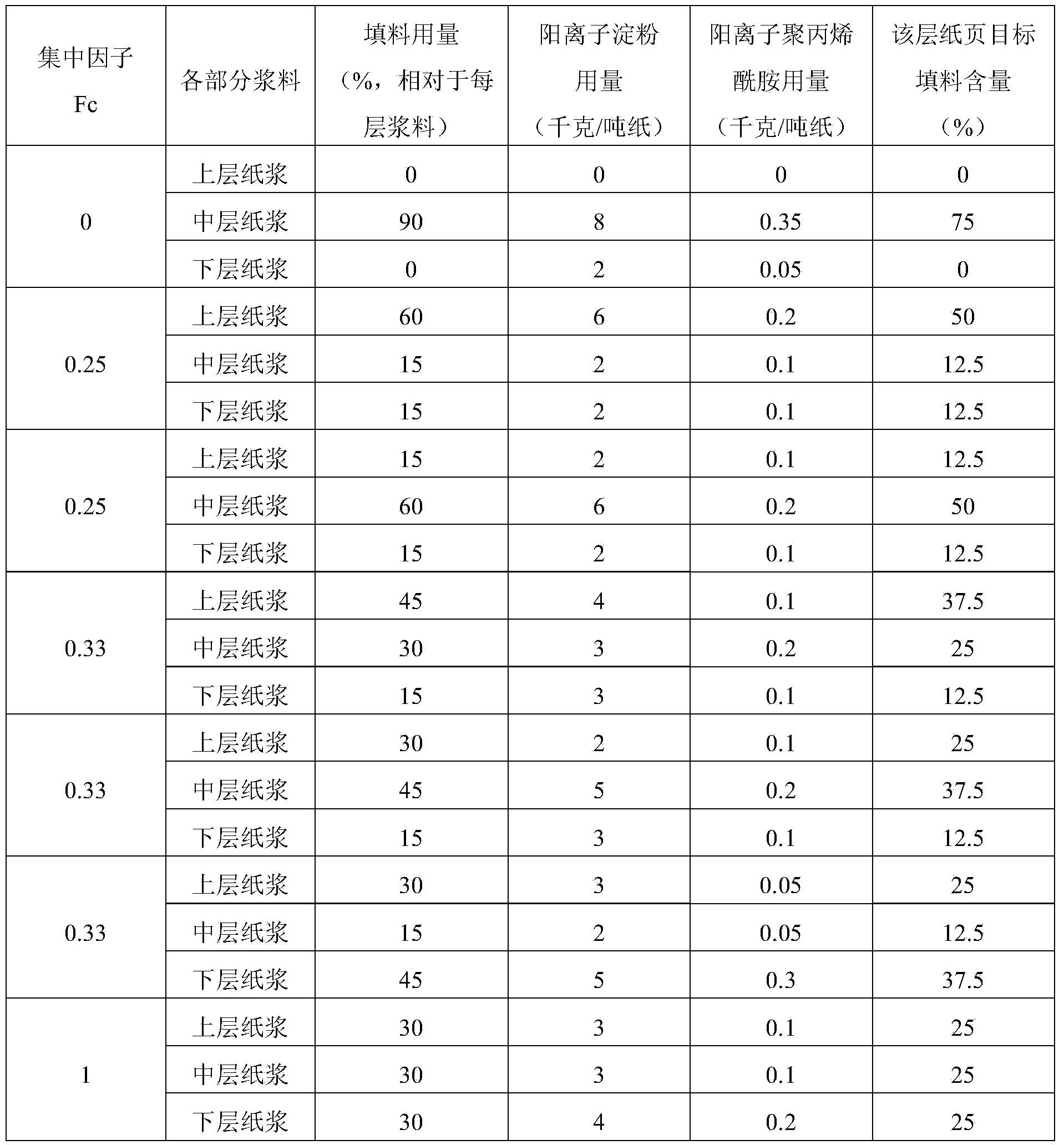

[0035] 4) Papermaking of paper sheets: divide the slurry prepared in step 2) into three parts (upper, middle and lower layers), and dilute each part of the slurry to a concentration of 0.1%; The absolute dry mass ratio of the total amount of fibers in the slurry with a beating degree of 30°SR is 30:70, and the final paper-forming filler content meets the target paper-forming filler content of 25% by adding retention aids.

[0036] Ac...

Embodiment 2

[0041] The paper-forming filler content of present embodiment is 25%, comprises the following steps:

[0042] 1) Disintegration of pulp: fully disintegrate and dehydrate the chemical mechanical pulp to make a slurry with a final concentration of 12%;

[0043] 2) Refining: refining the prepared slurry, the refining concentration is 12%, and the final beating degree of the slurry after refining is 50°SR;

[0044] 3) Preparation of filler suspension: prepare a calcium carbonate filler suspension with a concentration of 15%, and fully stir and disperse;

[0045] 4) Papermaking of paper sheets: the prepared slurry in step 2) is divided into three parts (upper, middle and lower layers), and each part of the slurry is diluted to a concentration of 0.3%; The absolute dry mass ratio of the total amount of fibers in the slurry with a beating degree of 50°SR is 10:90, and the final paper-forming filler content meets the target paper-forming filler content of 25% by adding retention aid ...

Embodiment 3

[0048] The paper-forming filler content of present embodiment is 25%, comprises the following steps:

[0049] 1) Disintegration of pulp: fully disintegrate and dehydrate the chemical softwood pulp to make a slurry with a final concentration of 9%;

[0050] 2) Refining: refining the prepared slurry, the refining concentration is 9%, and the final beating degree of the slurry after refining is 28°SR;

[0051]3) Preparation of filler suspension: prepare calcium carbonate filler suspension with a concentration of 20%, and fully stir and disperse;

[0052] 4) Papermaking of paper sheets: the prepared slurry in step 2) is divided into three parts (upper, middle and lower layers), and each part of the slurry is diluted to a concentration of 0.3%; The absolute dry mass ratio of the total amount of fibers in the slurry with a beating degree of 50°SR is 40:60, and the final paper-forming filler content meets the target paper-forming filler content of 25% by adding retention aids.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com