A manufacturing method of a double-warp flat wire drying net and a double-warp flat wire drying net

A manufacturing method and drying net technology, applied in the direction of papermaking, paper machine, filament/wire forming, etc., can solve the problems of small contact area, poor flatness of paper layer, unqualified paper surface quality, etc., to increase contact area, Small longitudinal extension and good paper effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

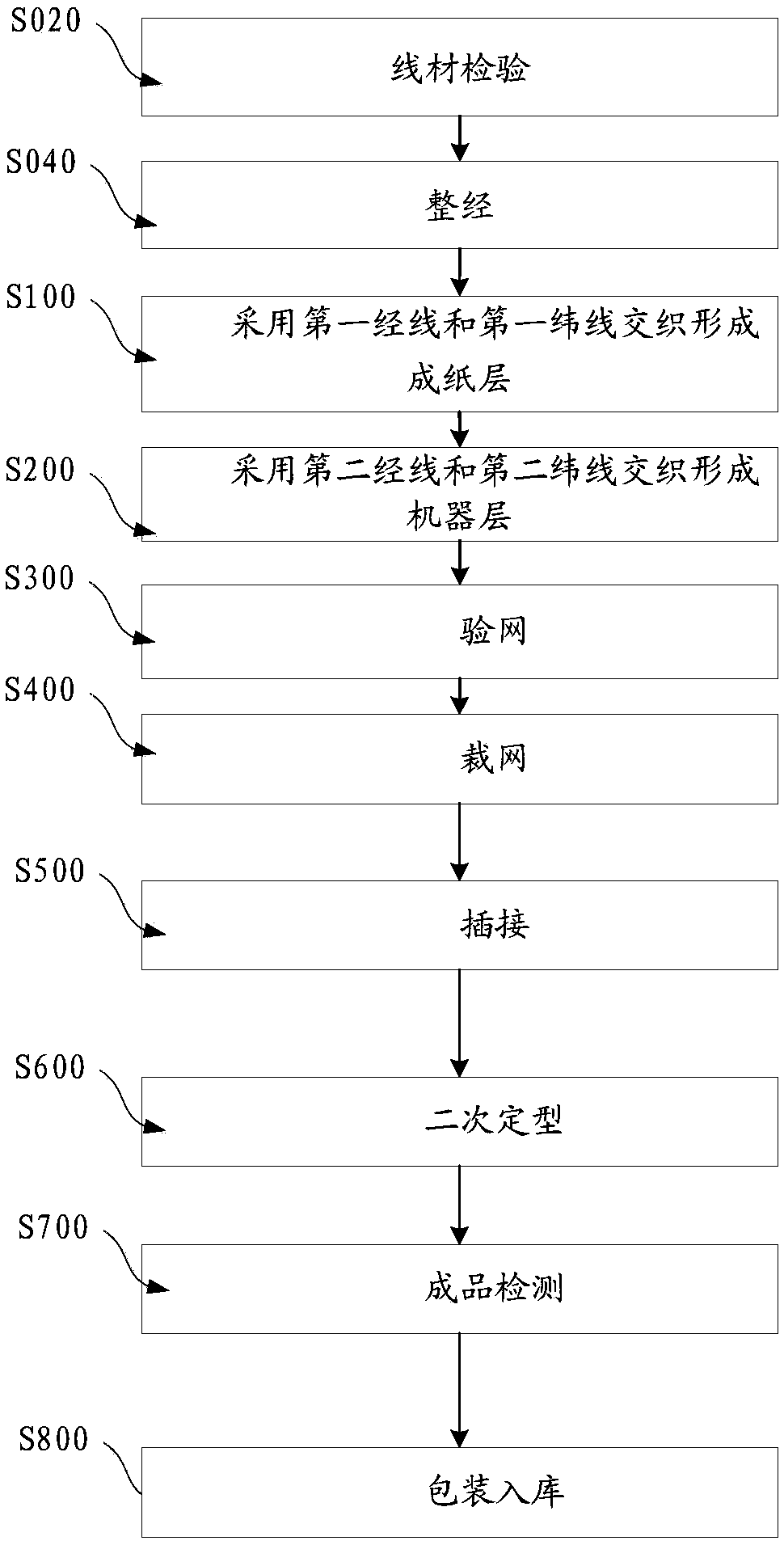

[0038] refer to figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the manufacturing method of a double warp flat wire drying net in the present invention. In this embodiment, the manufacturing method of the double warp flat wire drying net comprises:

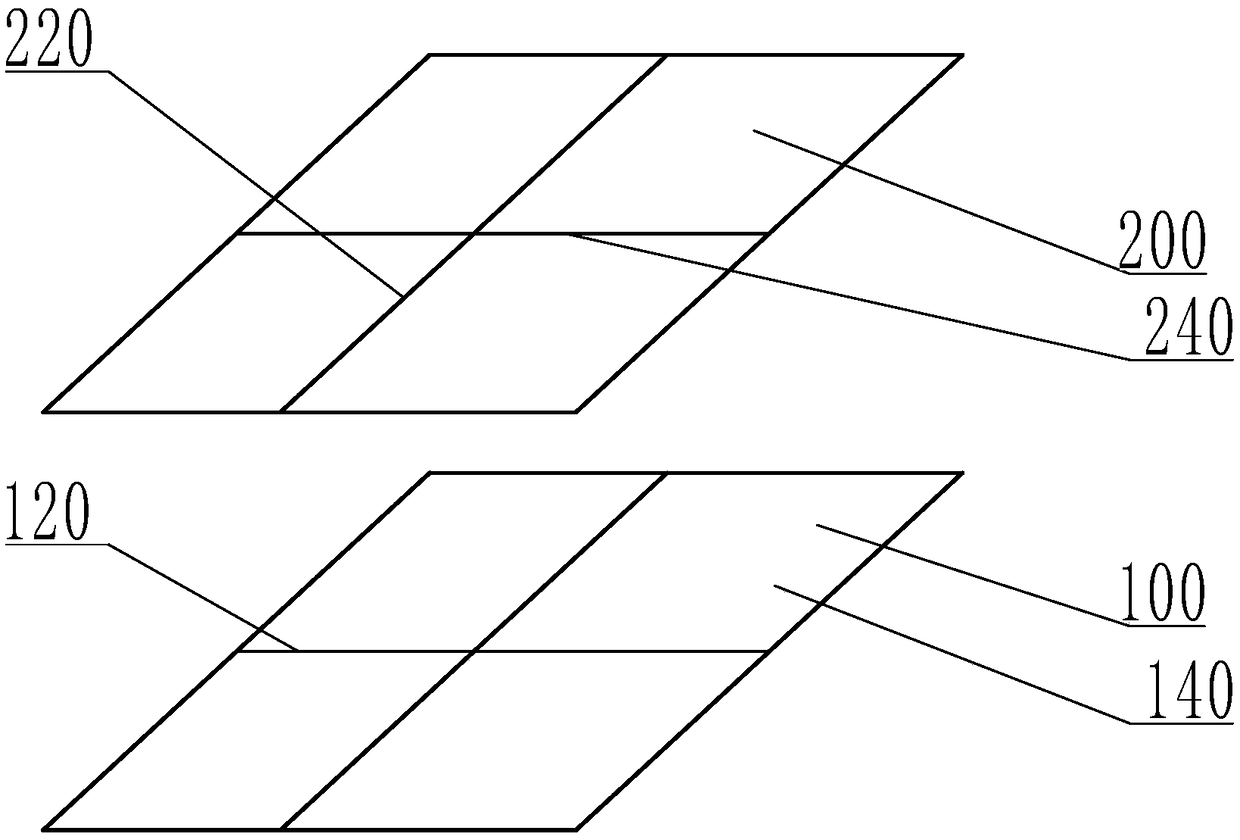

[0039] S100 interweaving the first warp and the first weft to form a paper layer;

[0040] S200 adopts the second warp thread and the second weft thread to interweave to form the machine layer.

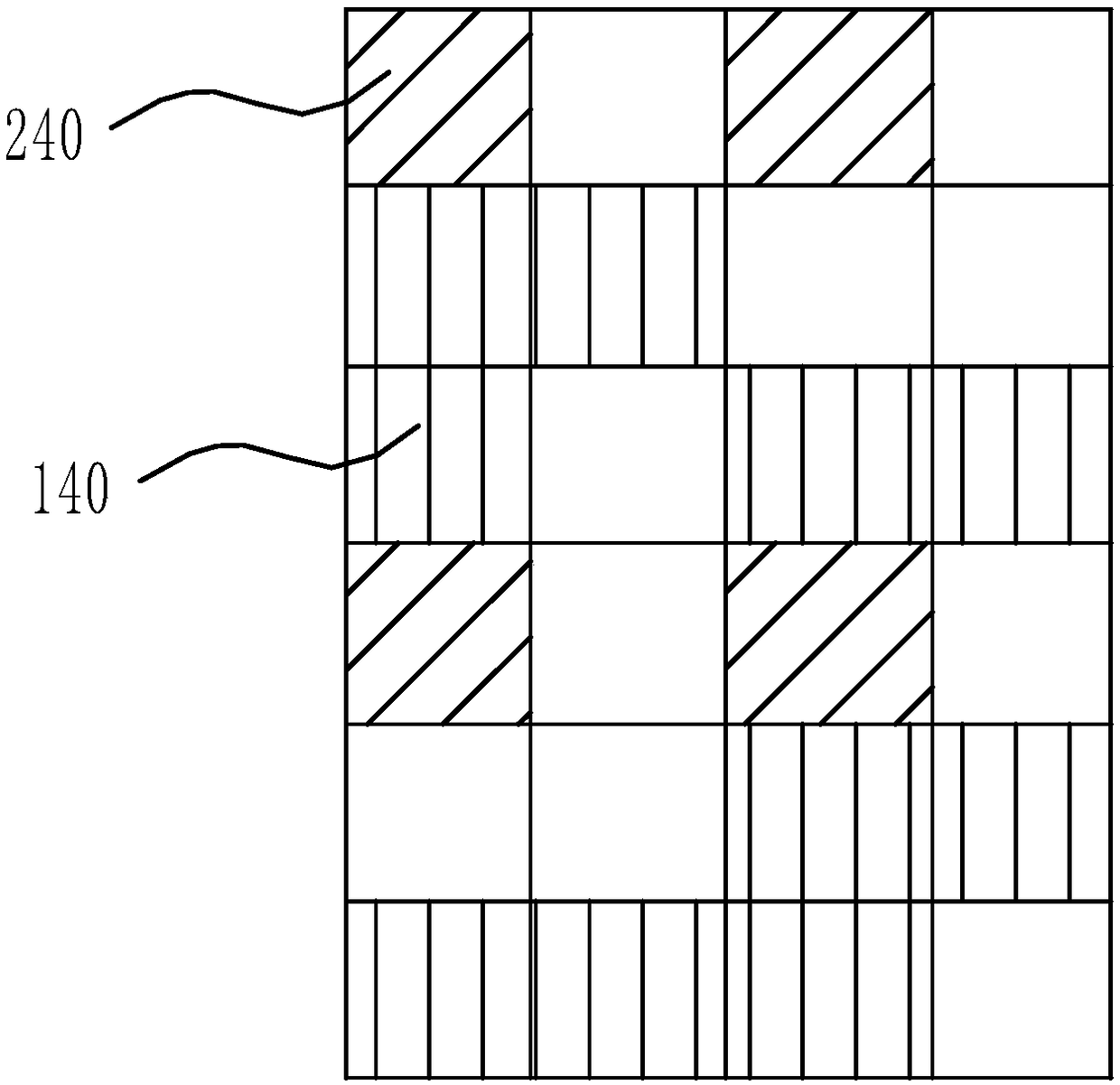

[0041] S100 uses the first warp thread and the first weft thread to interweave to form the paper layer step specifically comprising:

[0042] S120 using the first warp and the first weft to interweave at least two weaving methods to form a paper layer.

[0043] S200 uses the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com