Cationic waterborne polyurethane emulsion as well as preparation method and application thereof

A water-based polyurethane and cationic technology, which is applied in the field of papermaking, can solve the problems of inability to use additives and limit applications, and achieve the effects of improving surface strength, adjusting surface porosity, tearing degree and folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

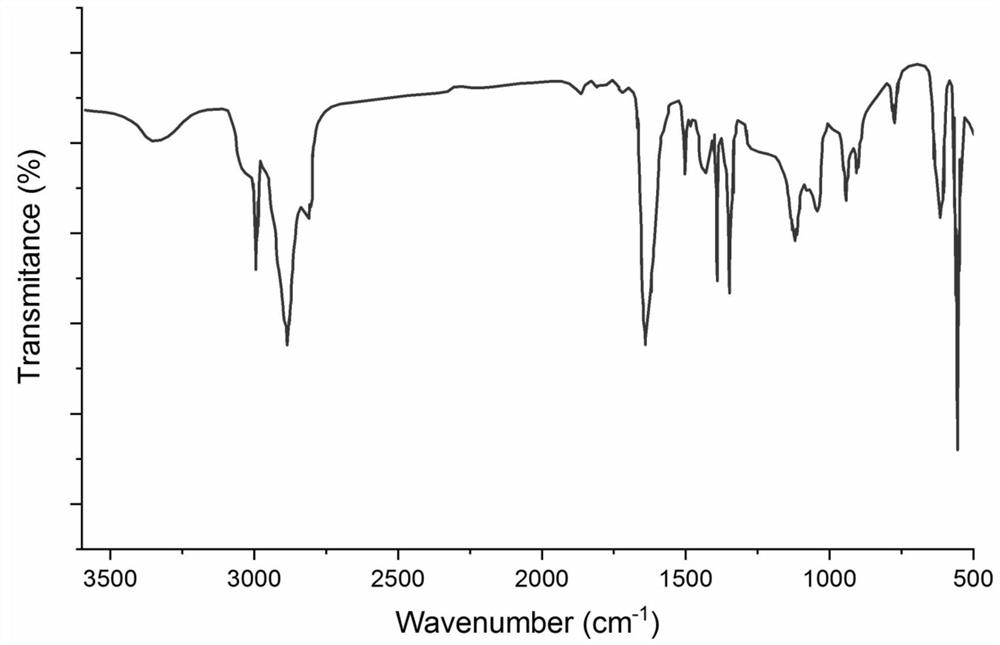

Image

Examples

Embodiment 1

[0047] A kind of preparation method of cationic water-based polyurethane emulsion of the present embodiment, described method specifically comprises the steps:

[0048] Step (1): First, pretreat the raw materials: refrigerate toluene-2,4-diisocyanate (TDI) in an environment < 4°C for later use; dehydrate tetrahydrofuran (THF) with molecular sieves for later use; prepare polyethylene glycol 200 (PEG-200) was vacuum dehydrated at 70°C and 0.08MPa for 12 hours, then placed in a desiccator for later use;

[0049] Step (2): Solution preparation: 50g (0.287mol) of TDI pretreated in step (1) was added to 167g of THF, and mixed to obtain a THF solution of TDI; and 14.4g (0.072mol) of step (1) After pretreatment, PEG-200 was added to 48g THF, and mixed to obtain a THF solution of PEG-200; wherein: in the THF solution of TDI, the concentration of TDI was 30wt%; in the THF solution of PEG-200, The concentration of PEG-200 is 30wt%;

[0050] Step (3): Add the THF solution of TDI that st...

Embodiment 2

[0055] A kind of preparation method of cationic water-based polyurethane emulsion of the present embodiment, described method specifically comprises the steps:

[0056] Step (1): First, pretreat the raw materials: refrigerate toluene-2,4-diisocyanate (TDI) in an environment <4°C for later use; dehydrate tetrahydrofuran (THF) with molecular sieves for later use; prepare polyethylene glycol 400 (PEG-400) was vacuum dehydrated at 70°C and 0.08MPa for 12 hours, then placed in a desiccator for later use;

[0057] Step (2): Solution preparation: 50g (0.287mol) of TDI pretreated in step (1) was added to 100g of THF, and mixed to obtain a THF solution of TDI; and 28.8g (0.072mol) of step (1) After pretreatment, PEG-400 was added to 57.6g THF, and mixed to obtain a THF solution of PEG-400; wherein: in the THF solution of TDI, the concentration of TDI was 50wt%; in the THF solution of PEG-400, The concentration of PEG-400 is 50wt%;

[0058] Step (3): Add the THF solution of TDI that s...

Embodiment 3

[0062] A kind of preparation method of cationic water-based polyurethane emulsion of the present embodiment, described method specifically comprises the steps:

[0063] Step (1): First, pretreat the raw materials: refrigerate toluene-2,4-diisocyanate (TDI) in an environment <4°C for later use; dehydrate tetrahydrofuran (THF) with molecular sieves for later use; prepare polyethylene glycol 800 (PEG-800) was vacuum dehydrated at 70°C and 0.08MPa for 12 hours, and then placed in a desiccator for later use;

[0064] Step (2): Solution preparation: 50g (0.287mol) TDI after step (1) pretreatment is added in 83.3g THF, mix, obtain the THF solution of TDI; And 57.6g (0.072mol) step (1) ) After pretreatment, PEG-800 was added to 96gTHF, and mixed to obtain a THF solution of PEG-800; wherein: in the THF solution of TDI, the concentration of TDI was 60wt%; in the THF solution of PEG-800, The concentration of PEG-800 is 60wt%;

[0065] Step (3): Add the THF solution of TDI that step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cobb value | aaaaa | aaaaa |

| Cobb value | aaaaa | aaaaa |

| Cobb value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com