Gap type forming section for a two fabric paper making machine

A technology of forming part and paper machine, applied in the field of gap forming part and double fabric gap forming part, can solve the problems of negative influence of forming fabric deflection control forming process, bad influence of paper product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

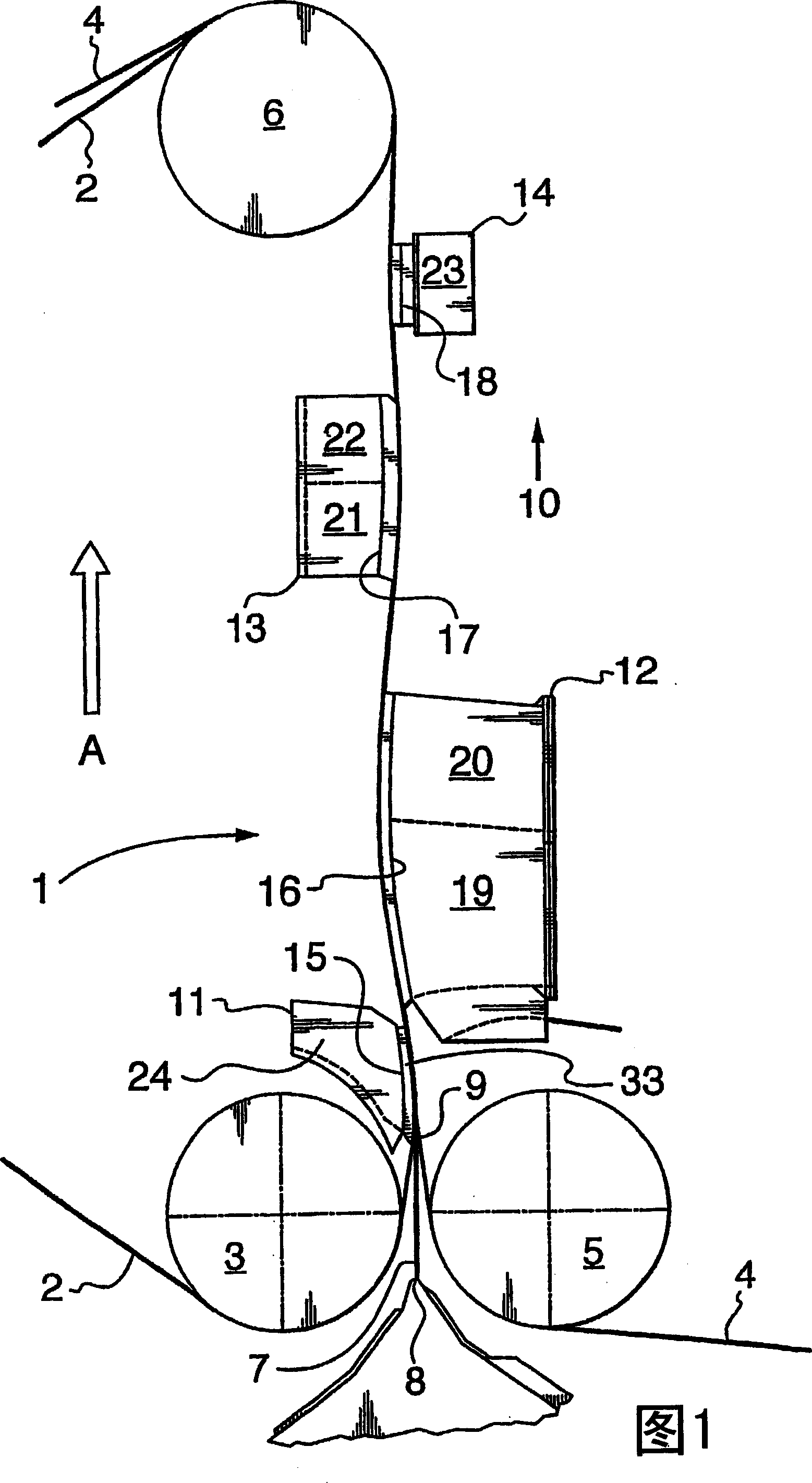

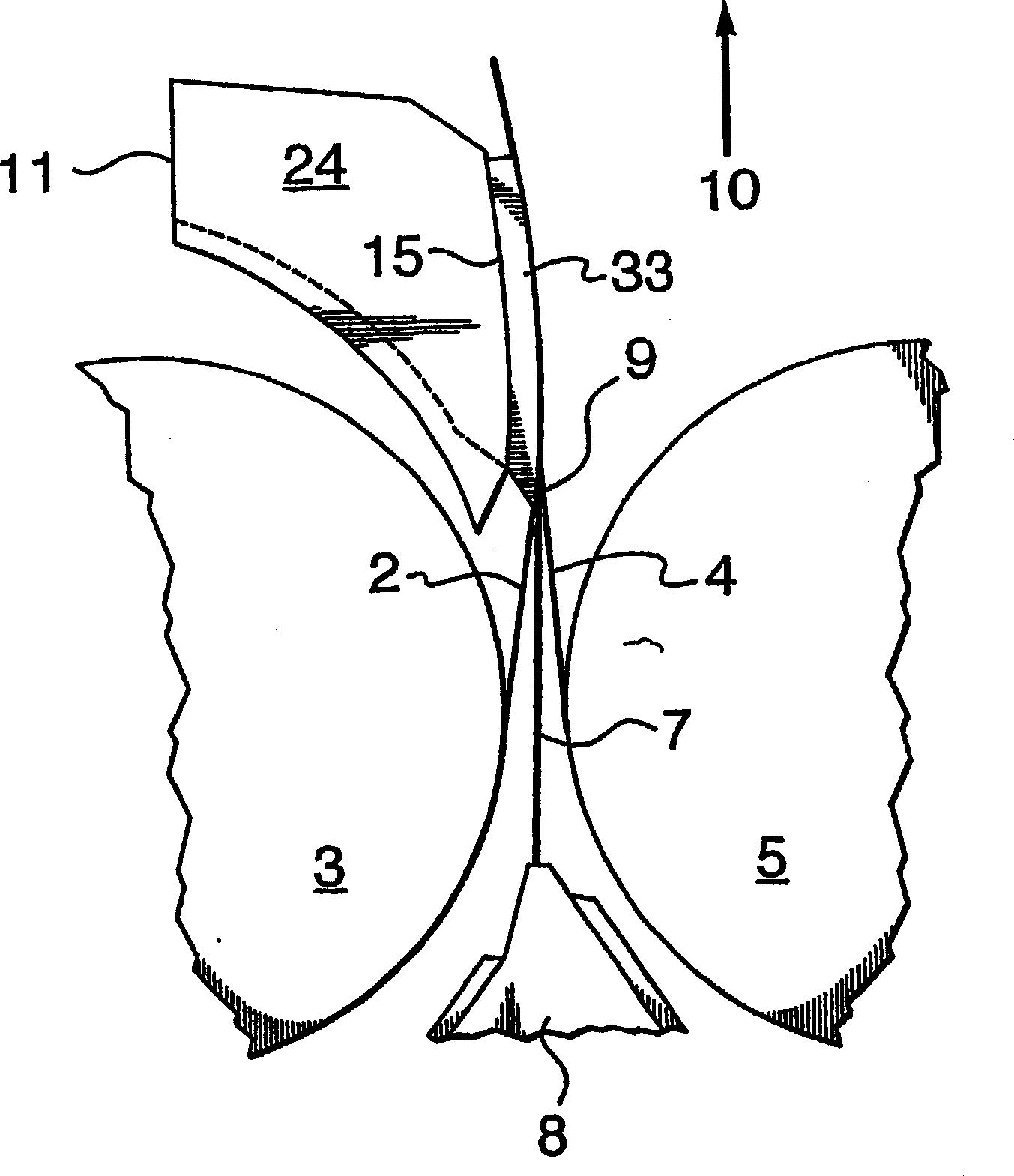

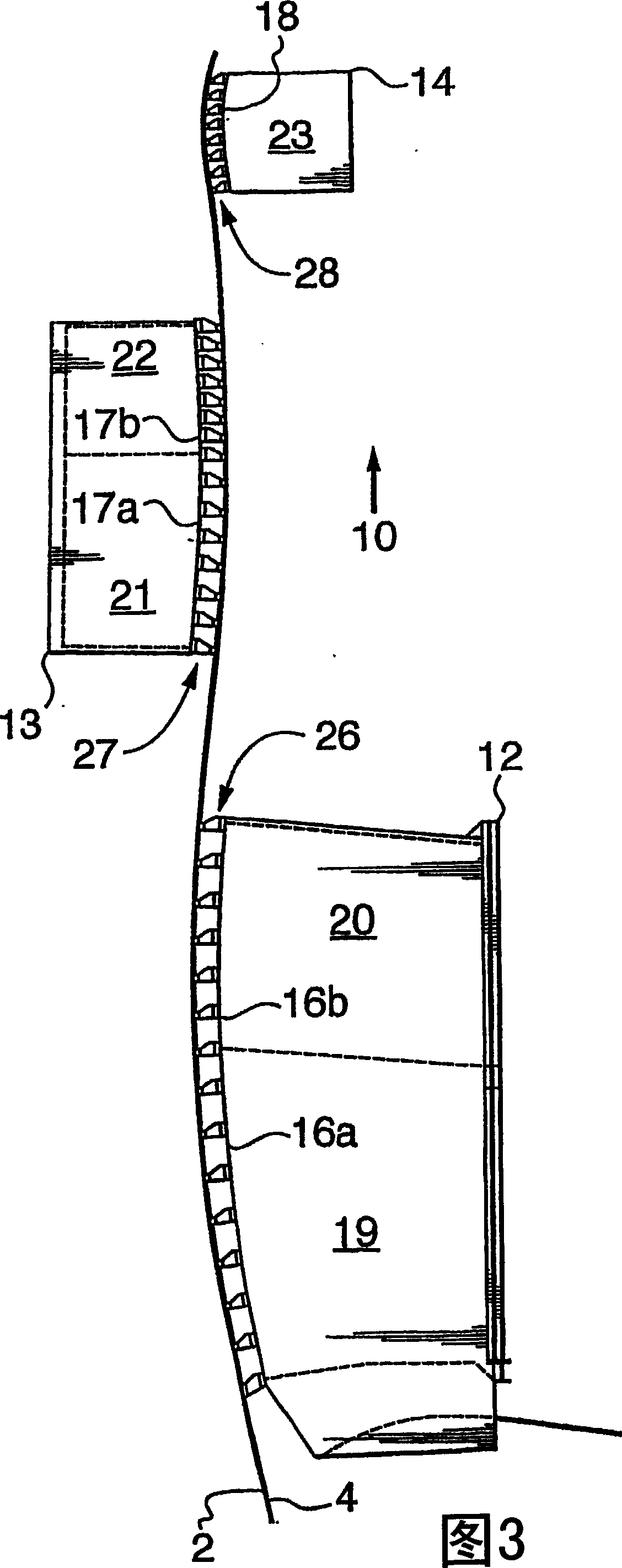

[0054] Referring firstly to Figure 1, there is shown a double fabric gap forming section 1 for a paper machine. The forming section 1 is arranged vertically; arrow A indicates the vertical direction.

[0055] The forming section 1 extends from one of the following two positions to the other, i.e. the conveying forming fabric 2 enters the forming section 1 around a first forming roll 3 and the pad forming fabric 4 enters the forming section 4 around a second forming roll 5. The position of the forming section, and the position where the transfer forming fabric 2 and the pad forming fabric 4 are separated after passing around the turning roll 6 . In the forming section 1 the two forming fabrics 2 , 4 sandwich between them the stock layer 7 released from the headbox slice 8 to the point of impact 9 . The two forming fabrics 2 , 4 are moved together through the forming section 1 in the machine direction indicated by arrow 10 . Thus, it is evident that the slurry layer 7 travels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com