Polyether ether ketone fiber composite paper and preparation method thereof

A technology of polyetheretherketone fiber and polyetheretherketone, which is applied in the field of polyether ether ketone fiber composite paper and its preparation, can solve the problems of low paper performance and poor paper-forming properties of polyether ether ketone fiber paper, and achieve Improve paper yield and comprehensive performance, good tightness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

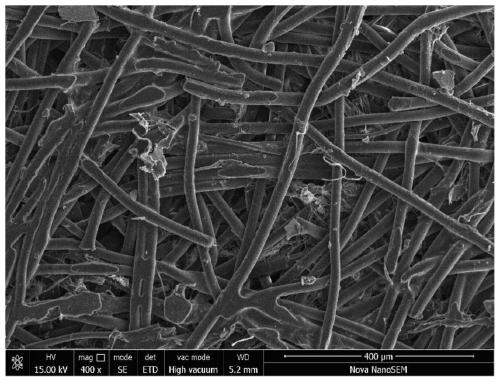

[0034] The preparation method of polyether ether ketone fiber composite paper of the present invention, the steps are as follows:

[0035] Step 1, using a degreasing agent and a surface treatment agent to perform degreasing treatment and surface treatment on the polyetheretherketone chopped fibers respectively, and after drying, obtain the treated polyether ether ketone chopped fibers;

[0036] Step 2, dispersing the treated polyetheretherketone chopped fibers and para-aramid pulp in an aqueous solution containing a dispersant, stirring and dispersing evenly, to obtain a fiber slurry;

[0037] Step 3: Vacuum filter the fiber slurry and dry to obtain polyether ether ketone fiber base paper;

[0038] Step 4, dissolving polyether ether ketone dioxoketone in an organic solvent to obtain an impregnation solution;

[0039] Step 5. Fully immerse the PEEK fiber base paper obtained in Step 3 in the impregnation solution, dry to remove the organic solvent, and heat press once to obtain...

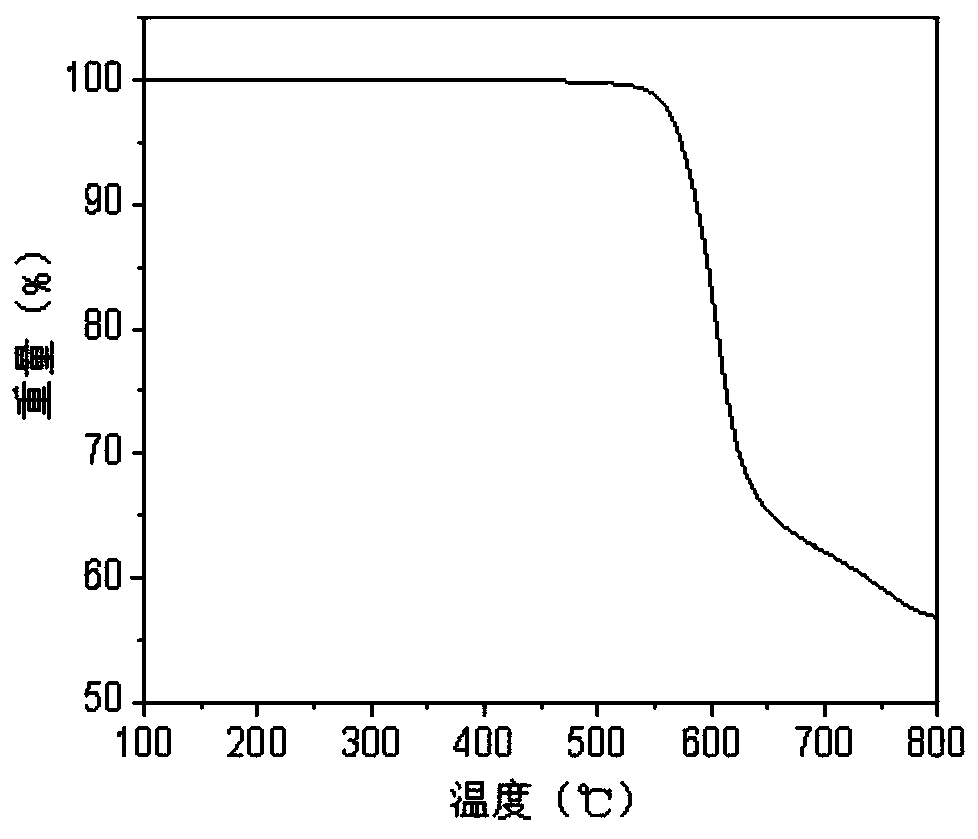

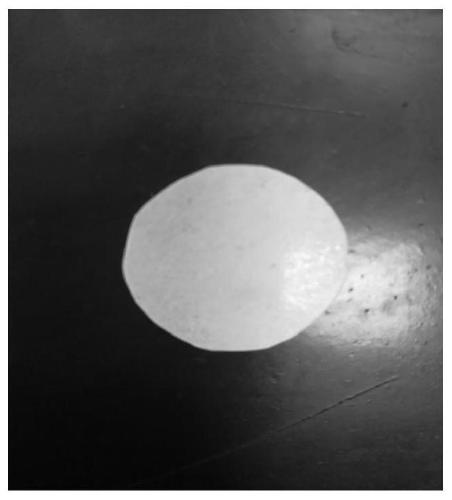

Embodiment 1

[0055] Add 3mmPEEK chopped fibers to petroleum ether first, stir and wash, filter, and then add the concentration of 1.2×10 - 3 mol / L sodium dodecylbenzenesulfonate aqueous solution, stirring to loosen and disperse the fibers into a single state, and drying to obtain the treated PEEK chopped fibers. Disperse PEEK chopped fibers and para-aramid pulp with a mass ratio of 90:10 in 0.01% PEO aqueous solution, and stir at 3500 rpm for 2 hours to obtain fiber slurry. The fiber slurry is vacuum filtered and dried to obtain a polyether ether ketone fiber base paper. The polyetheretherketone-dioxone was dissolved in tetrahydrofuran to obtain an impregnation solution with a concentration of the polyetheretherketone-dioxone of 3%. Fully impregnate the polyetheretherketone fiber base paper with the impregnation solution, dry it, and perform a hot press after the solvent tetrahydrofuran is removed to obtain a preliminary polyetheretherketone fiber composite paper; The hot pressing time ...

Embodiment 2

[0057] Add 4mmPEEK chopped fibers to petroleum ether at a concentration of 1.2×10 -3 mol / L sodium dodecylbenzenesulfonate aqueous solution, stirring to loosen and disperse the fibers into a single state, and drying to obtain the treated PEEK chopped fibers. Disperse PEEK chopped fibers and para-aramid pulp with a mass ratio of 90:10 in 0.03% PEO aqueous solution, and stir at 20000 rpm for 2 hours to obtain fiber slurry. The fiber slurry is vacuum filtered and dried to obtain a polyether ether ketone fiber base paper. The polyetheretherketone-dioxone was dissolved in tetrahydrofuran to obtain an impregnation solution with a concentration of the polyetheretherketone-dioxone of 2%. Fully impregnate the polyetheretherketone fiber base paper with the impregnation solution, dry it, and perform a hot press after the solvent tetrahydrofuran is removed to obtain a preliminary polyetheretherketone fiber composite paper; The hot pressing time is 5min. The primary polyetheretherketone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com