Solvent-free silicon coating machine

A solvent-free, silicon-coated technology, used in coatings, devices for coating liquids on surfaces, etc., can solve the problems of wasting resources, polluting the environment, unable to meet the requirements of low coating weight, etc., and achieves good lubrication performance, low The effect of coating quantitative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

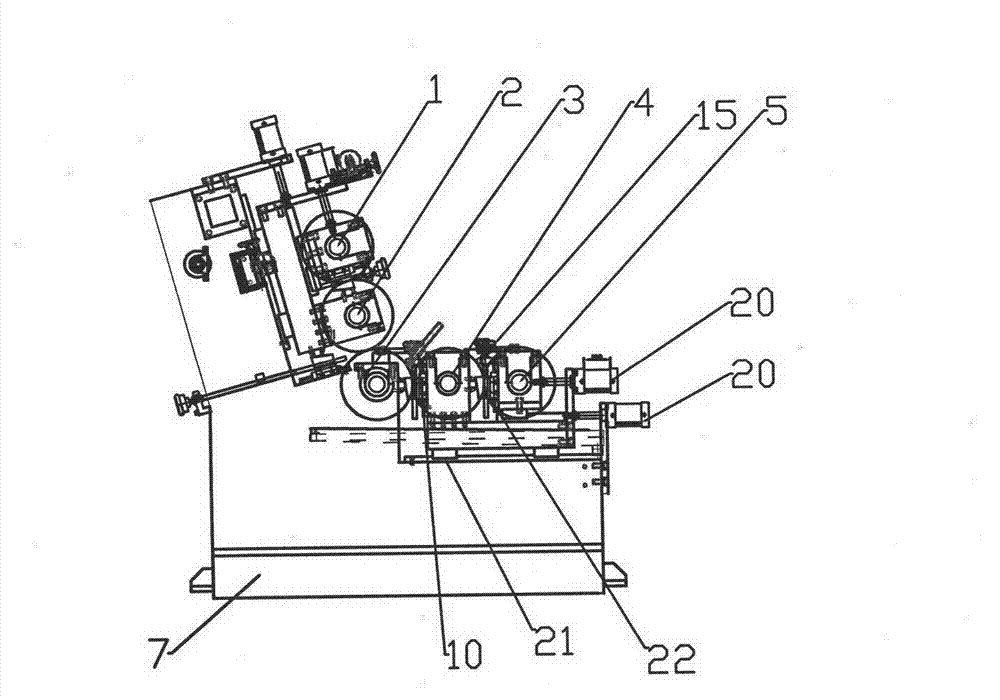

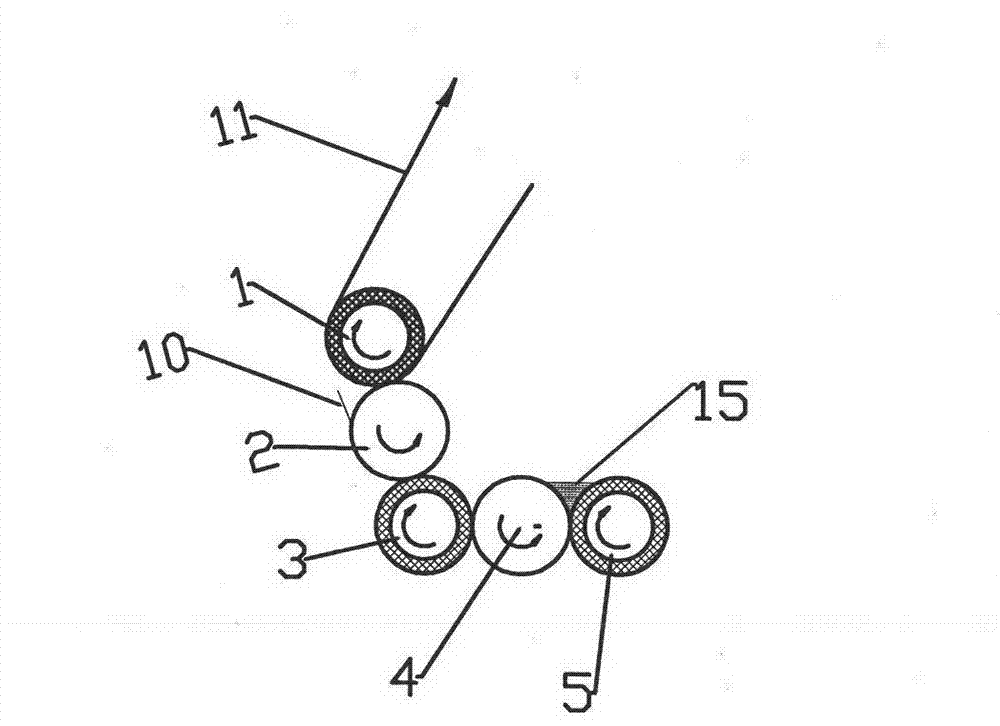

[0030] The solvent-free silicon coating machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

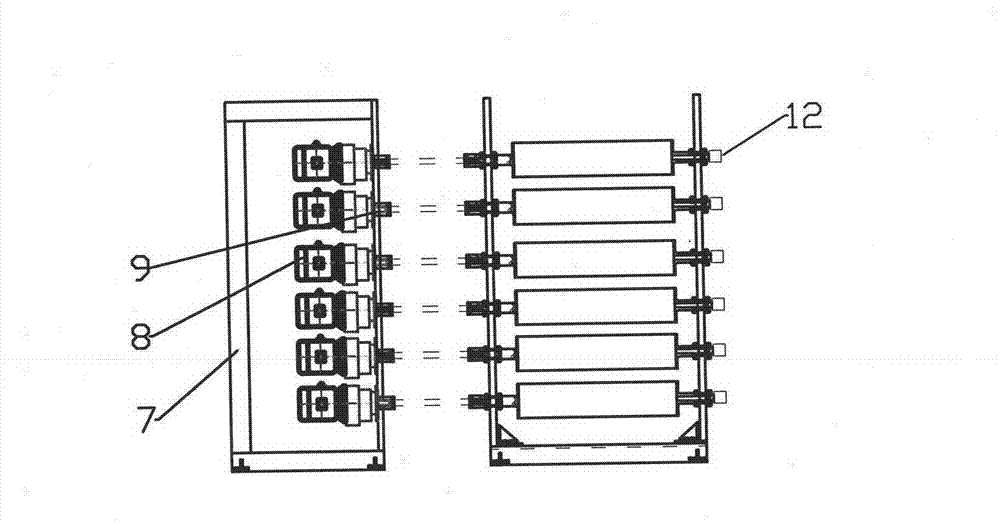

[0031] like Figure 1 to Figure 7 As shown, the solvent-free silicon coating machine of the present invention includes a frame 7, a gear reduction frequency conversion motor 8, a universal joint 9 and five or six rollers (numbering 1, 2, 3, 4, 5, 6), and the gear reduction The variable frequency motor 8 is installed on the frame 7, and the gear reduction variable frequency motor 8 is connected with the rollers through the universal coupling 9, and the rollers are installed on the frame. There are five rollers, including three rubber rollers and two steel rollers, and the rubber rollers and steel rollers are alternately distributed. There are five rollers, including two rubber rollers and three steel rollers, and the rubber rollers and steel rollers are alternately distributed. There are six rollers, including thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com