Decorative film coated paper for bamboo veneer and production method and device of decorative film coated paper

A production device and production method technology, applied to paper, papermaking, special paper, etc., can solve the problems of short storage time, poor surface finish and flatness of boards, and difficult separation, and achieve good anti-aging and anti-corrosion performance, Good surface finish and smoothness, prolonged storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

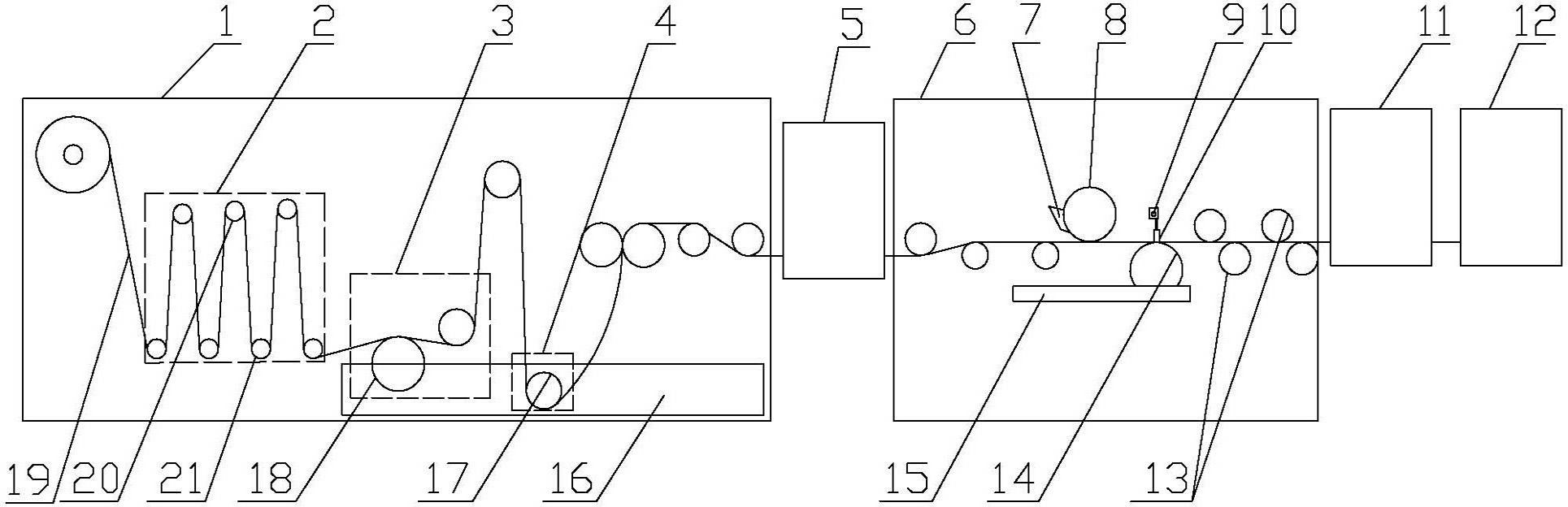

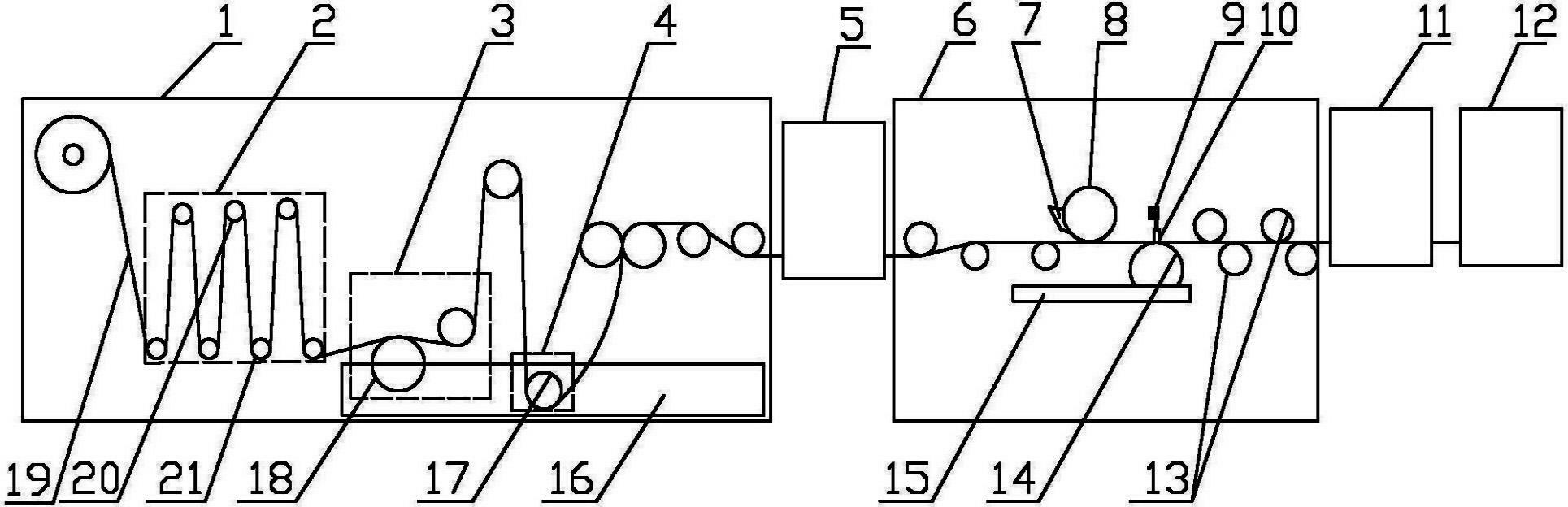

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] A kind of decorative coated paper for bamboo plywood, the base paper 19 is made after one-time gluing, one-time drying, two-time gluing, two-time drying, cutting and packaging, and the amount of glue on the surface of the base paper 19 is 140g / ㎡~180 g / ㎡, stored at room temperature below 30°C for 90 days, the wear resistance reaches 380 revolutions and there is no bottoming phenomenon. The present embodiment glue is phenolic resin glue.

[0023] The weight of base paper used in the present invention is 45g / ㎡~55g / ㎡ (50g / ㎡ in this embodiment).

[0024] A kind of production method of decorative coated paper for bamboo plywood as above, it comprises the following steps:

[0025] (1) One-time gluing: send the base paper 19 into the glue solution in the primary gluing mechanism 1 and soak it for 2s-3s (2s in this embodiment), and the viscosity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com