M-aramid fiber mica paper and preparation method thereof

A technology of aramid fiber and aramid fibril, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material treatment, paper, etc., which can solve the problem of easy lint and powder falling on the surface, low tear strength, Combining the problems of low strength to achieve the effect of improving mechanical strength and dielectric strength, excellent tensile strength, improving mechanical properties and dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

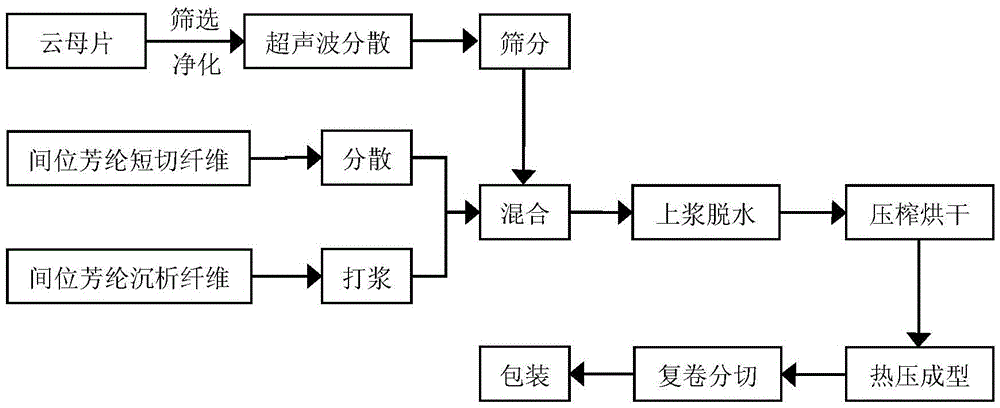

[0031] see figure 1 , the preparation method of mica paper of the present invention, comprises the following steps:

[0032] (1) Preparation of mica sheet slurry: winnowing muscovite fragments or sericite fragments, removing impurities such as air-dried mica, rust mica, stained mica and wood chips that are not suitable for copying, and further removing impurities such as fine silt through a pressure sieve, Then use ultrasonic treatment to peel off the mica sheet into mica sheet. The ultrasonic treatment conditions are: power 800-3000W, time 1-10h; Mesh: ≧40 mesh Grading ratio=(1~3):(4~6):3 The ratio is combined, and the mica sheet slurry with a mass concentration of 1~6% is prepared;

[0033] (2) Dispersion of meta-aramid short-cut fibers: disperse meta-aramid short-cut fibers with a length of 4-12 cm and a fineness of 2D in deionized water, and add a polyethylene oxide solution with a mass concentration of 0.03-0.08% Finally, use a trough beater to fully decompose and dispe...

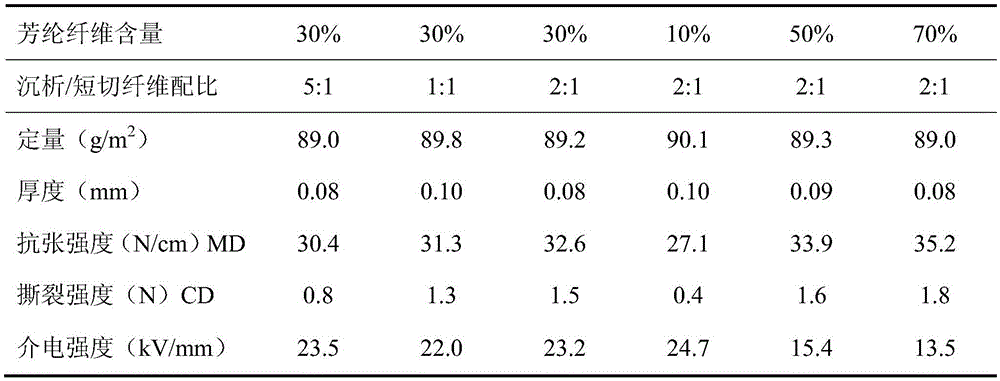

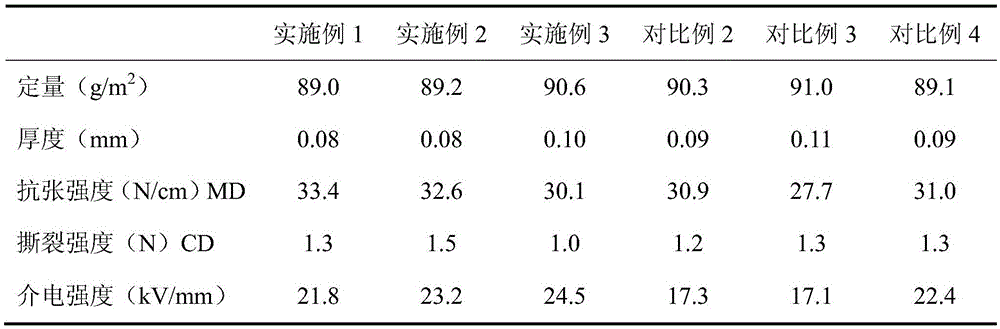

Embodiment 1

[0038] Embodiment 1 adopts the method of the present invention to prepare meta-aramid fiber mica paper

[0039]Select muscovite fragments with a thickness ≤ 1.6mm, remove impurities through winnowing and pressure sieving, and use ultrasonic treatment to peel off the mica flakes into mica flakes, with a power of 800W and a time of 10h. Classify the particle size of the mica flakes through a sieve, combine them according to the ratio of ≦20 mesh: 20~40 mesh: ≧40 mesh particle size ratio = 1:6:3, and prepare a slurry with a mass concentration of 1%. ; Use a trough beater to disperse the length 12mm, the meta-aramid chopped fiber of the fineness 2D, add the polyethylene oxide (mass concentration is 0.03%) of relative absolute dry mass 0.3%, disperse and disperse and make the mass concentration be 0.01% Slurry; the aramid precipitated fiber is beaten by a disk refiner, the fiber length distribution is 35-140 mesh, the beating degree is 45°SR, and the slurry with a mass concentratio...

Embodiment 2

[0040] Embodiment 2 adopts the method of the present invention to prepare meta-aramid fiber mica paper

[0041] Select muscovite fragments with a thickness ≤ 1.6mm, remove impurities through winnowing and pressure sieving, and use ultrasonic treatment to peel off mica flakes into mica flakes, with a power of 1500W and a time of 4h. Classify the particle size of the mica flakes through a sieve, combine them according to the ratio of ≦20 mesh: 20~40 mesh: ≧40 mesh particle size ratio = 2:5:3, and prepare a slurry with a mass concentration of 3%. ; Use a trough beater to disperse the length 6mm, the meta-aramid chopped fiber of the fineness 2D, add the polyoxyethylene (mass concentration is 0.05%) of relative absolute dry mass 0.5%, disperse and disperse and make the mass concentration be 0.02% Slurry; the aramid precipitated fiber is beaten by a disc refiner, the fiber length distribution is 35-140 mesh, the beating degree is 55°SR, and the slurry is prepared with a mass concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com