Coaxial wound heat exchanger

A heat exchanger and winding technology, which is applied in the field of coaxial winding heat exchangers, can solve the problems of reducing heat exchange efficiency of heat exchangers, difficulty in guaranteeing machining accuracy, and difficulty in processing inner tubes, etc., achieving compact structure, reducing The effect of processing difficulty and disturbance increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

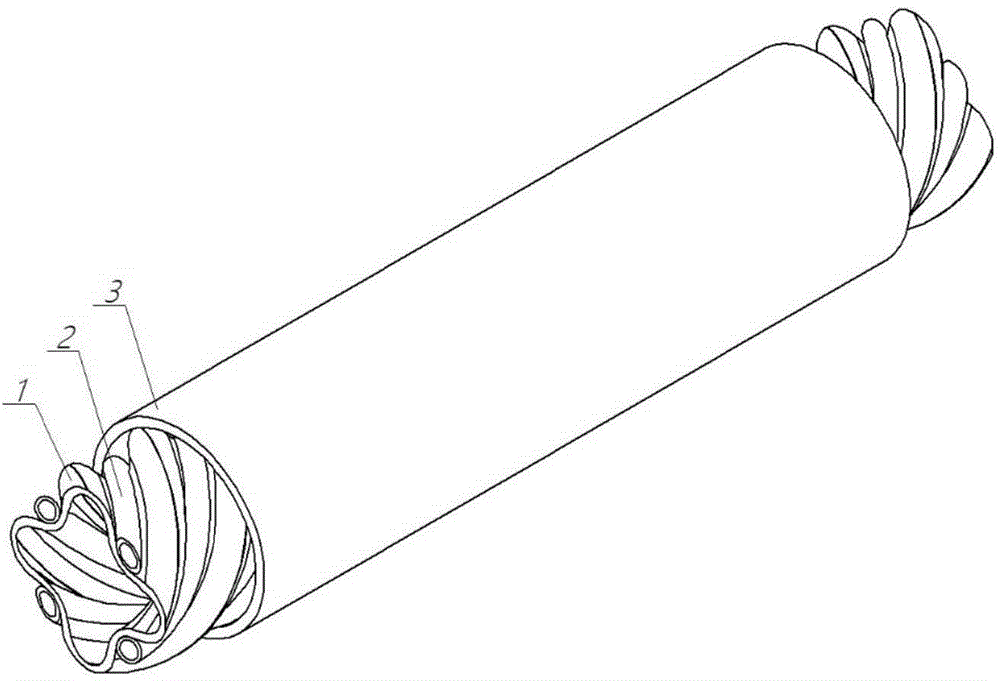

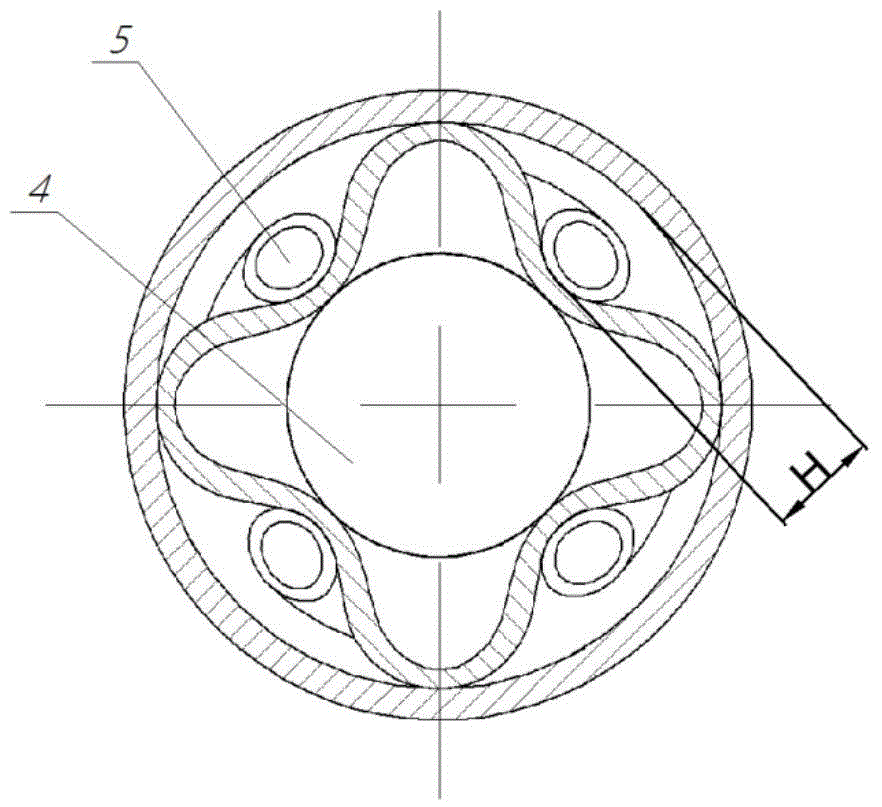

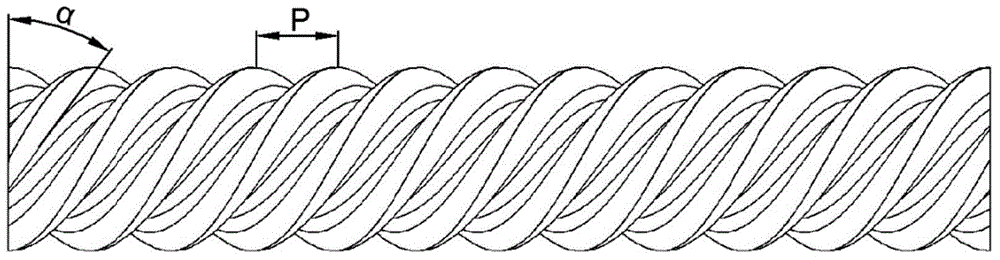

[0019] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes: a spiral corrugated tube 1, several capillary tubes 2 and a thermal insulation layer 3, wherein: each capillary tube 2 is respectively wound in the groove between the external threads of the spiral corrugated tube 1, and the spiral groove The outer layer of corrugated tube 1 and capillary tube 2 is covered with thermal insulation layer 3, the flow medium inside the spiral corrugated tube 1 is brine, and the flow medium 5 inside capillary tube 2 is refrigerant, and the brine and refrigerant flow countercurrently .

[0020] Each capillary 2 is wound uniformly along the helical direction of the spiral corrugated tube 1 .

[0021] The structure of the fluid channel 4 containing the flowing medium inside the spiral corrugated pipe 1 is a quincunx-shaped spiral channel whose cross-sectional shape is centrally symmetrical.

[0022] Using the spiral corrugated tube 1 as the heat exchange tube, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com