LED (Light Emitting Diode) light emitting module and manufacturing method thereof

A light-emitting module and LED chip technology, which is applied to semiconductor devices of light-emitting elements, light sources, electric light sources, etc., can solve the problems that it is difficult to meet the heat dissipation requirements of high-power LED lighting devices, and the thermal resistance of lighting devices is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

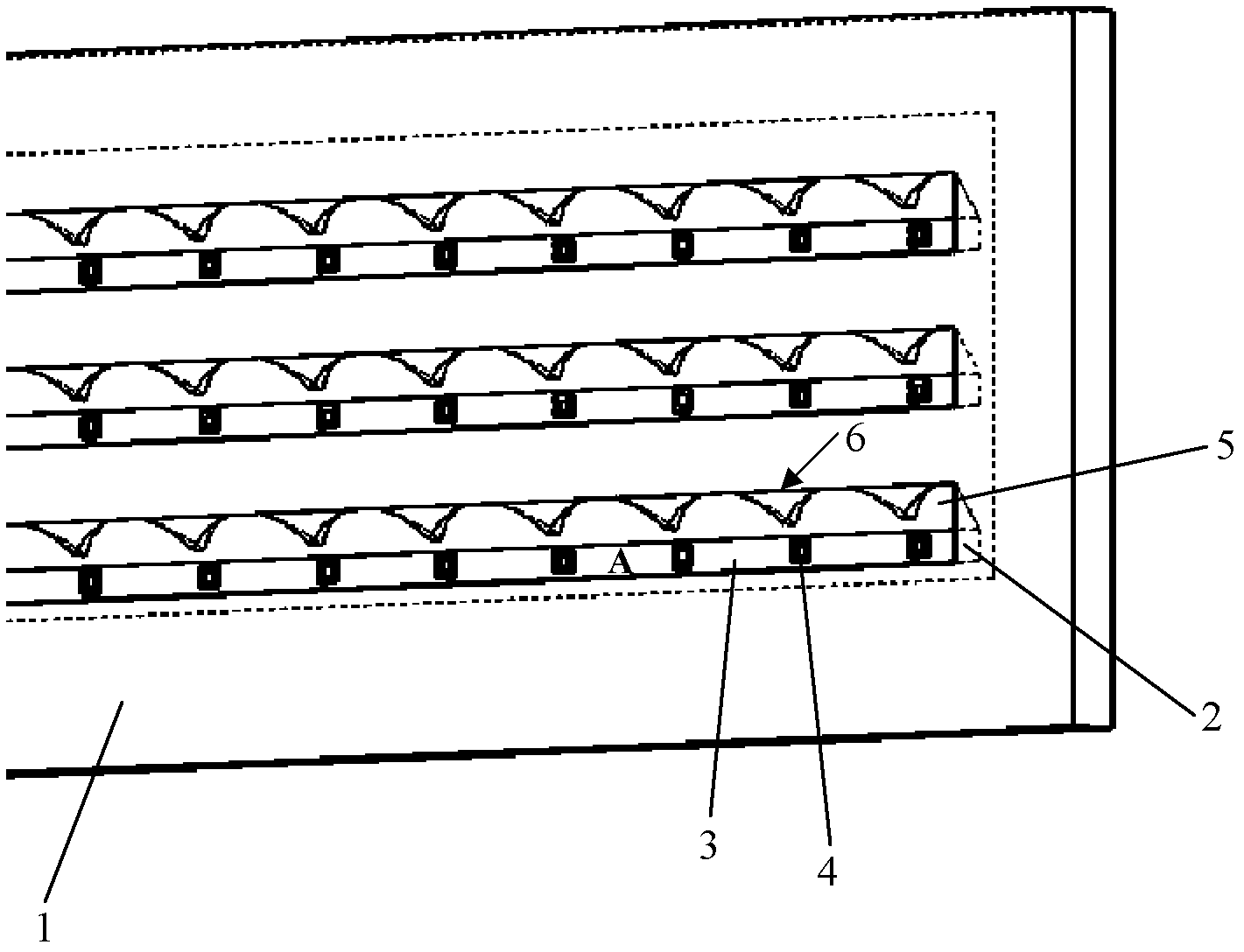

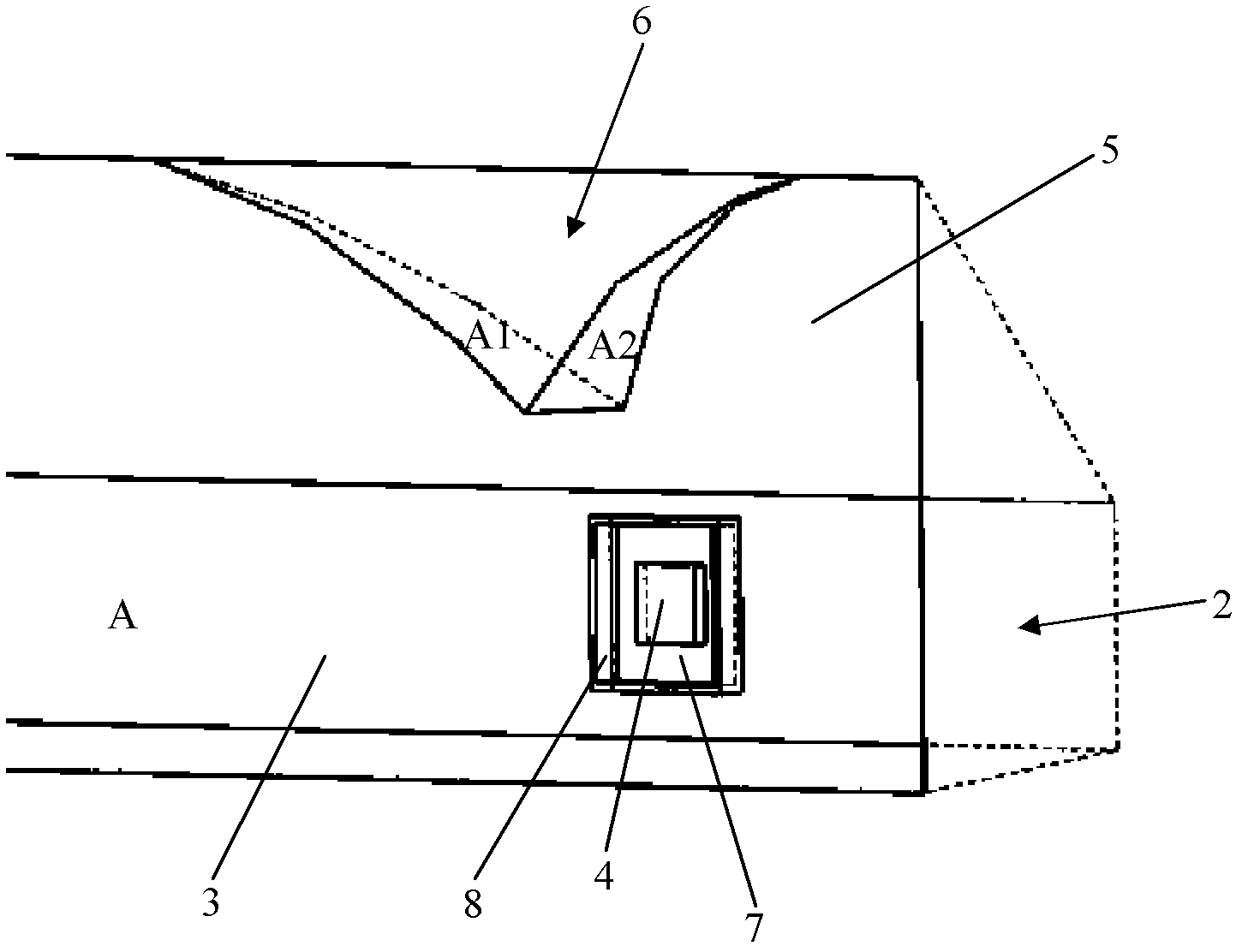

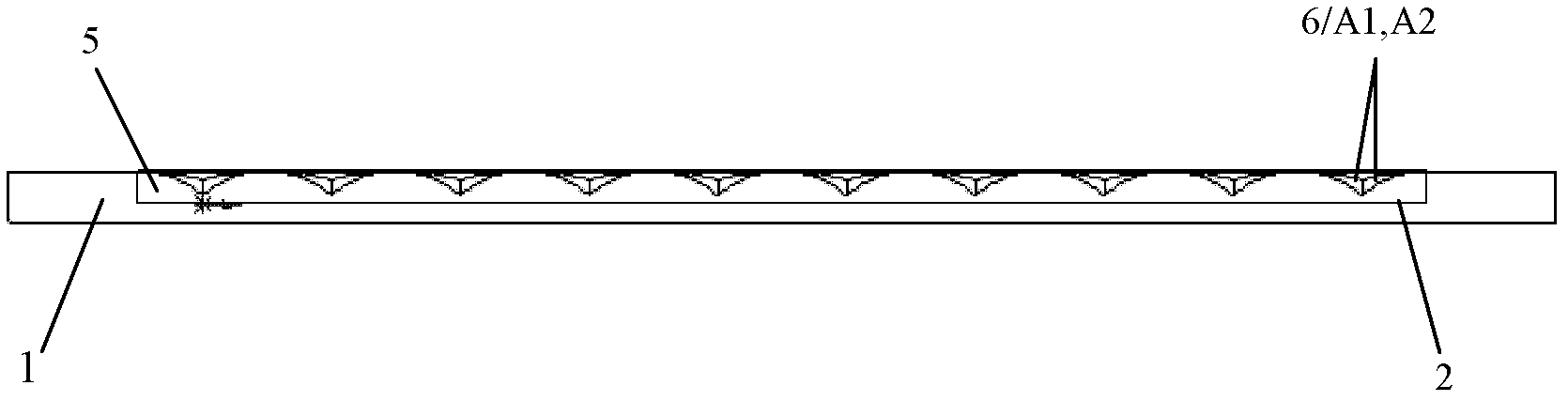

[0031] figure 1 A three-dimensional view of the LED light-emitting module according to the present invention is shown in, wherein the LED light-emitting module has a bottom plate 1, a reflector 5, a printed circuit board 3 and an LED chip 4. In this preferred embodiment, in order to save manufacturing costs and reduce assembly steps, the base plate 1 is subjected to a processing process such as hot die casting or stamping, so that the reflector 5 is integrally formed on the base plate 1. After this treatment process, at least one groove 2 (three in this embodiment) is formed in the bottom plate 1 at the same time, and the groove 2 has a flat bottom and side walls. The bottom may be processed by milling, for example, to form a mounting surface A for mounting the printed circuit board 3, wherein the LED chip 4 is mounted on the printed circuit board 3 in particular by using the COB process. The sidewall of the groove 2 itself serves as the reflector 5, thereby further avoiding li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com