Lighting device

A light-emitting device and light-emitting element technology, which is applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problems of light-emitting elements 12 that heat energy is difficult to dissipate, heat dissipation is not good, and the efficiency of light emission cannot be effectively improved. Heat dissipation performance and product reliability, avoiding thermal resistance and aging problems, reducing production cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A light emitting device according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

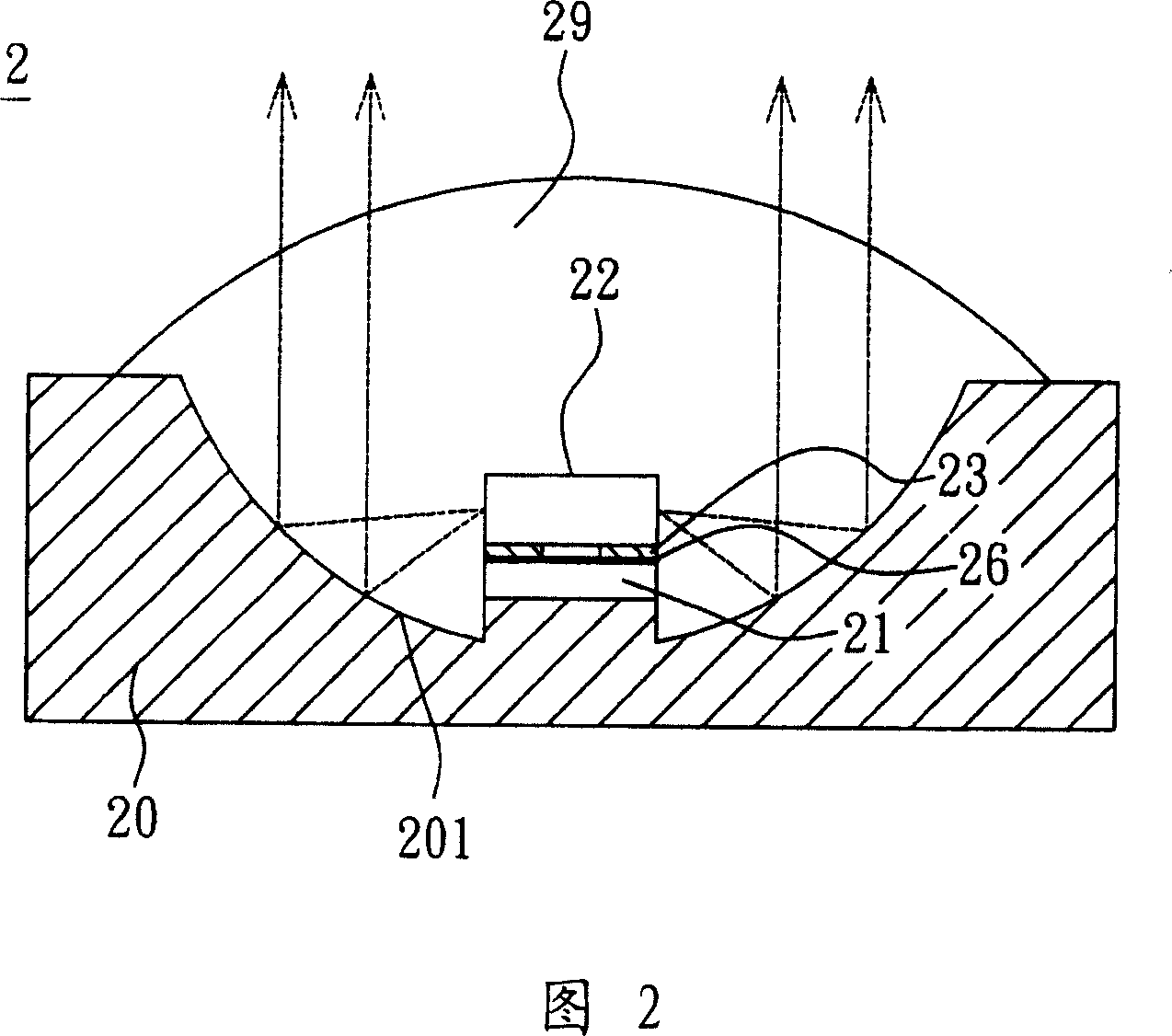

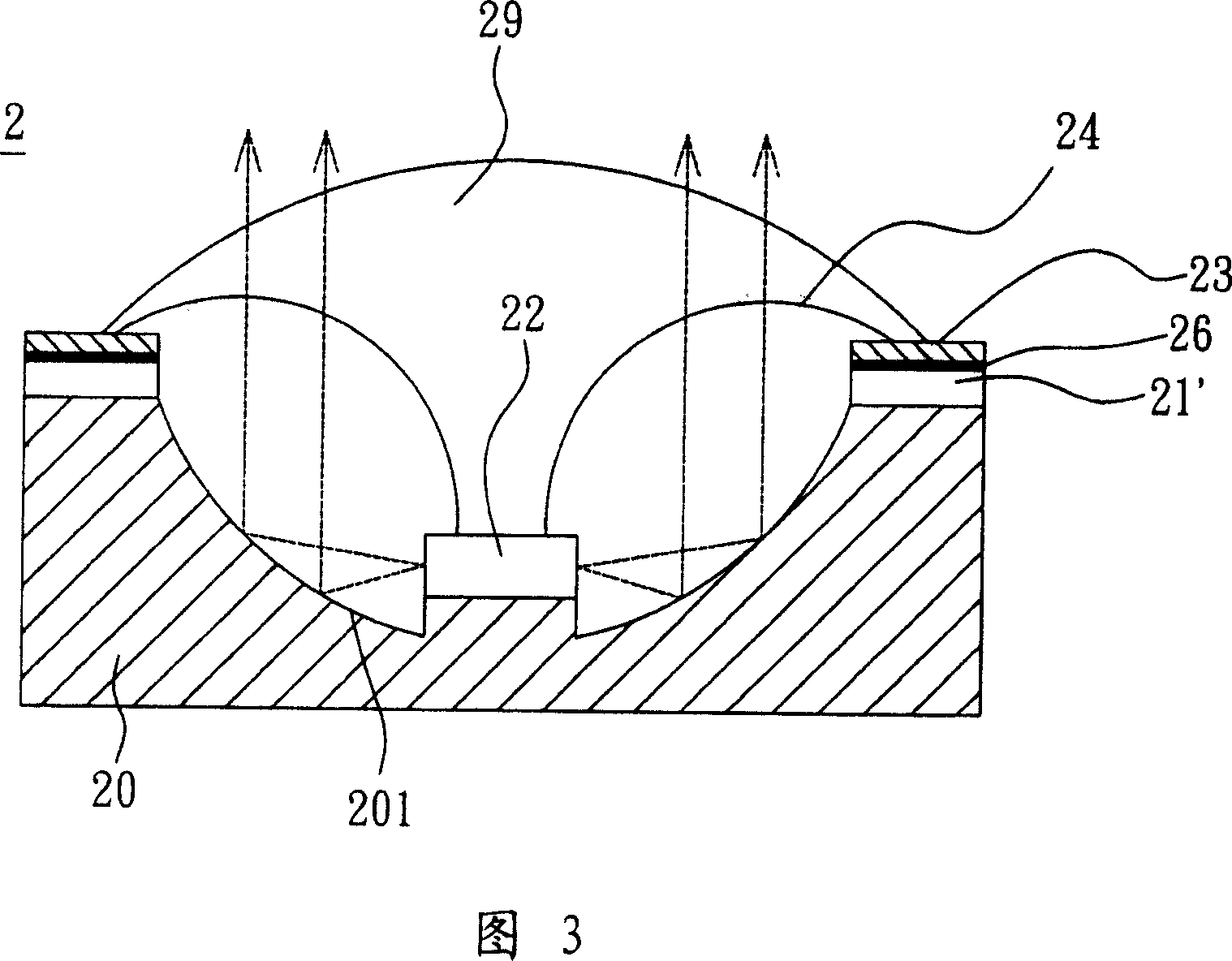

[0035] Referring to FIG. 2, a light emitting device 2 according to a preferred embodiment of the present invention includes a substrate 20, a first insulating layer 21, a connection layer 26, a metal layer 23, at least one light emitting element 22 and a protective layer. 29.

[0036] In this embodiment, the material of the substrate 20 can be made of at least one of copper, aluminum, magnesium, titanium and alloys thereof to provide better thermal conductivity; in addition, the material of the substrate 20 can also be made of ceramic materials , to provide better thermal conductivity, wherein, the surface of the substrate 20 has a structure 201 for improving light extraction efficiency.

[0037] In this embodiment, the first insulating layer 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com