Radiating packaging structure of semiconductor power device

A technology of power devices and packaging structures, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., to achieve the effect of improving heat dissipation efficiency and effect, fast and uniform heat, and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

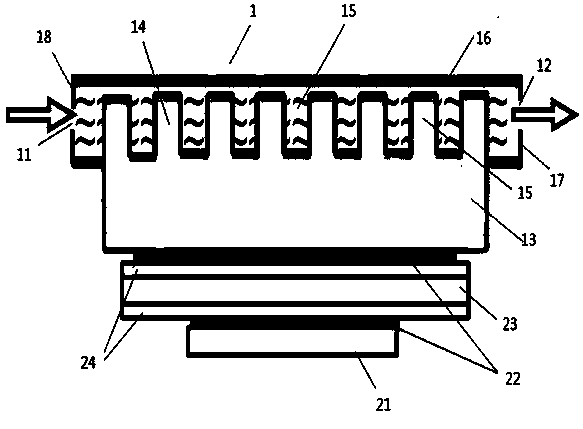

[0032] like figure 1 As shown, the present embodiment provides a heat dissipation packaging structure of an IGBT module, including a heat dissipation housing 1, and the heat dissipation housing 1 is jointly surrounded by a wall 16, a first side wall 17, a second side wall 18 and a cover plate 13. A square shell is formed, wherein the wall 16, the first side wall 17 and the second side wall 18 are integrally formed into an open groove, and a sealing groove (not shown in the figure) is arranged on the edge of the opening groove, and the inside of the sealing groove A sealing ring is provided, and the edge of the cover plate 13 cooperates with the sealing ring to realize the sealing installation between the cover plate 13 and the opening groove, thereby forming a cavity for containing the cooling liquid, wherein the cooling liquid inlet is arranged on the second side wall 18 11. A cooling liquid outlet 12 is provided on the first side wall 17, and the cooling liquid is introduce...

Embodiment 2

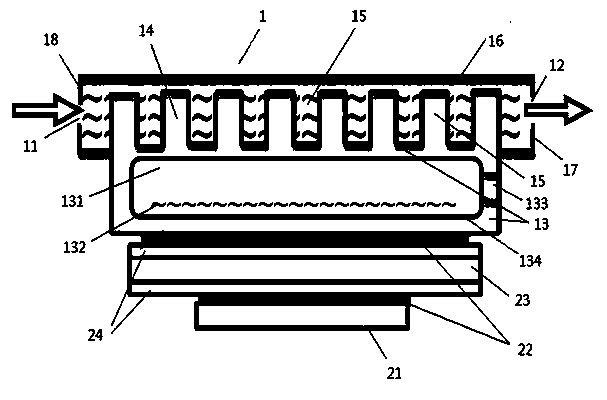

[0037] This embodiment is a modification based on Embodiment 1. Compared with Embodiment 1, the heat dissipation package structure provided by this embodiment is mainly changed in that the structure of the cover plate 13 is changed.

[0038] like figure 2 As shown, the inside of the cover plate 13 is provided with a vacuum cavity 131, the inside of the vacuum cavity 131 is equipped with a liquid phase change medium 132, and the liquid phase change medium 132 is a new fluorocarbon compound, and the vacuum cavity 131 Several capillary structures (not shown in the figure) that facilitate the uniform distribution of the liquid phase change medium 132 are formed on the surface 134 close to the heat transfer direction of the semiconductor power device, that is, grooves. The cross-sectional shape of the capillary structure is triangular. Of course, the cross-sectional shape of the capillary structure may also be trapezoidal or rectangular.

[0039] When the IGBT power device is in ...

Embodiment 3

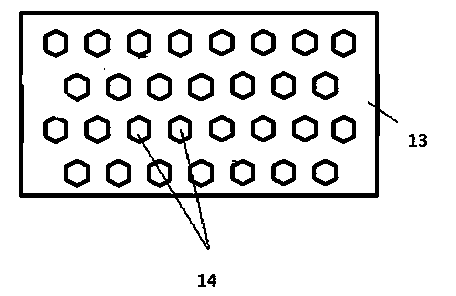

[0043] This embodiment provides a heat dissipation packaging structure for semiconductor power devices, which is a modification of Embodiment 2, and the difference with Embodiment 2 is that the arrangement of the heat dissipation component 14 is changed.

[0044] like Figure 4 As shown, in this embodiment, the cover plate 13 of the heat dissipation housing 1 is provided with six rows of the heat dissipation components 14, and the heat dissipation components 14 in two adjacent rows are arranged in a staggered manner to form a wave-shaped fluid Channel 15 , the wavy fluid channel 15 includes several crests and troughs between adjacent crests, wherein the heat dissipation component 14 is a heat dissipation fin, and the heat dissipation fin is welded on the cover plate 13 .

[0045] Of course, the number of columns of the heat dissipation assembly 14 can be designed in other ways as required, for example, 2 columns, 4 columns, 6 columns, etc.

[0046] When the IGBT power device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com