Heat dissipation device with three-dimensional pulsation heat pipes

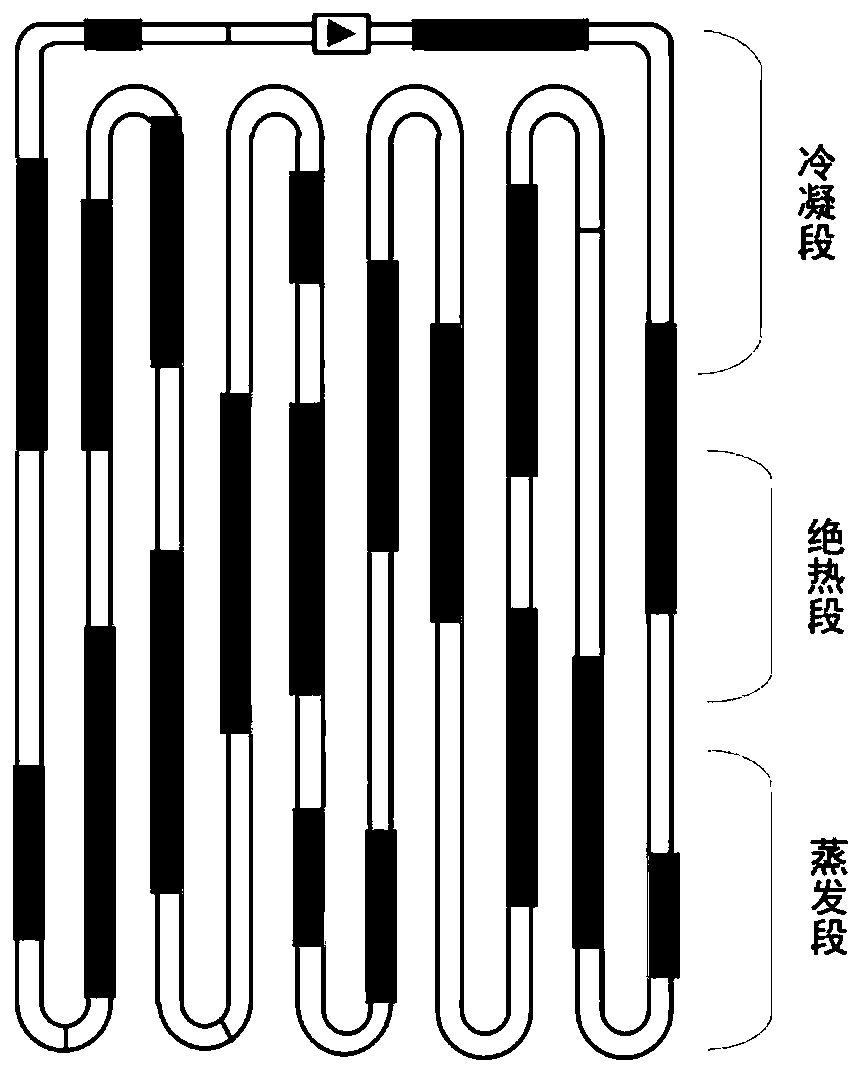

A technology of pulsating heat pipes and cooling devices, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems affecting the performance of pulsating heat pipes, incomplete condensation in the condensation section, and dryness in the evaporation section, so as to avoid thermal resistance and start-up The effect of reducing power and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

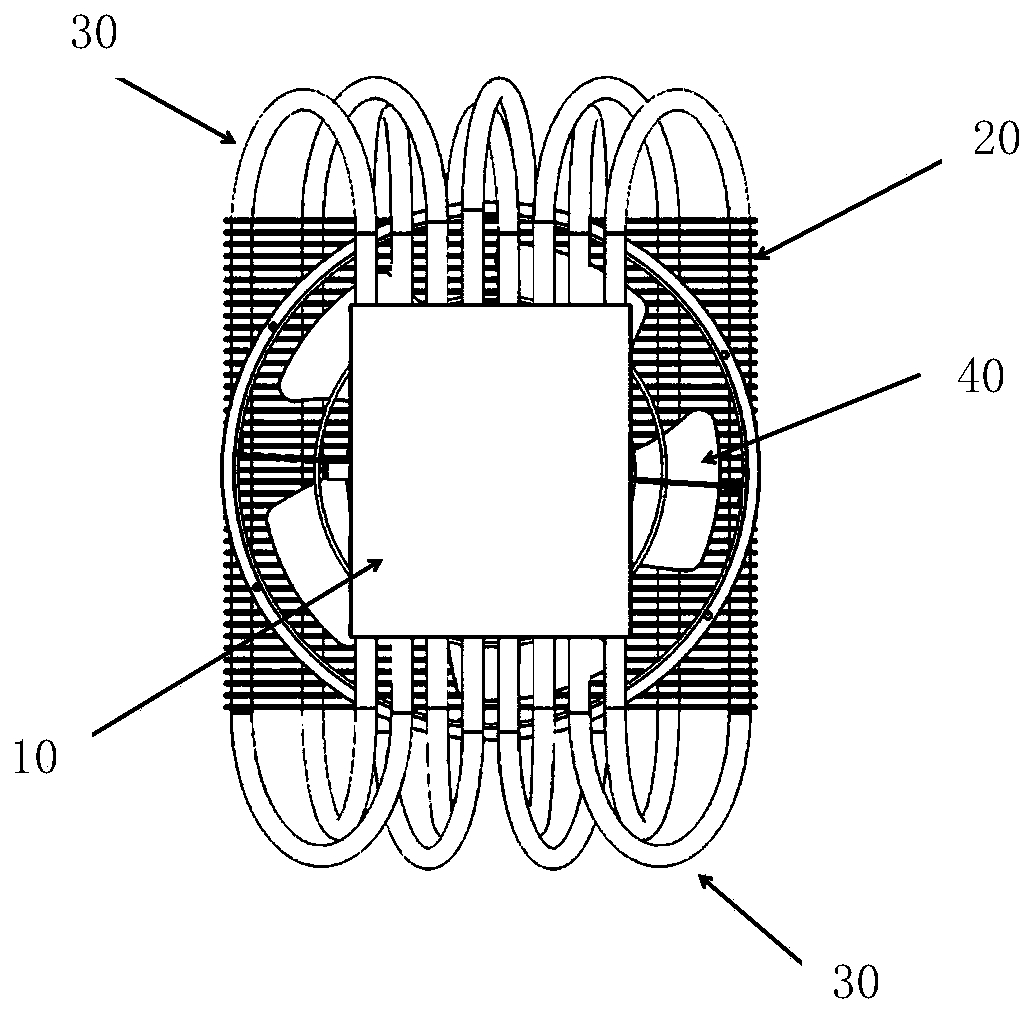

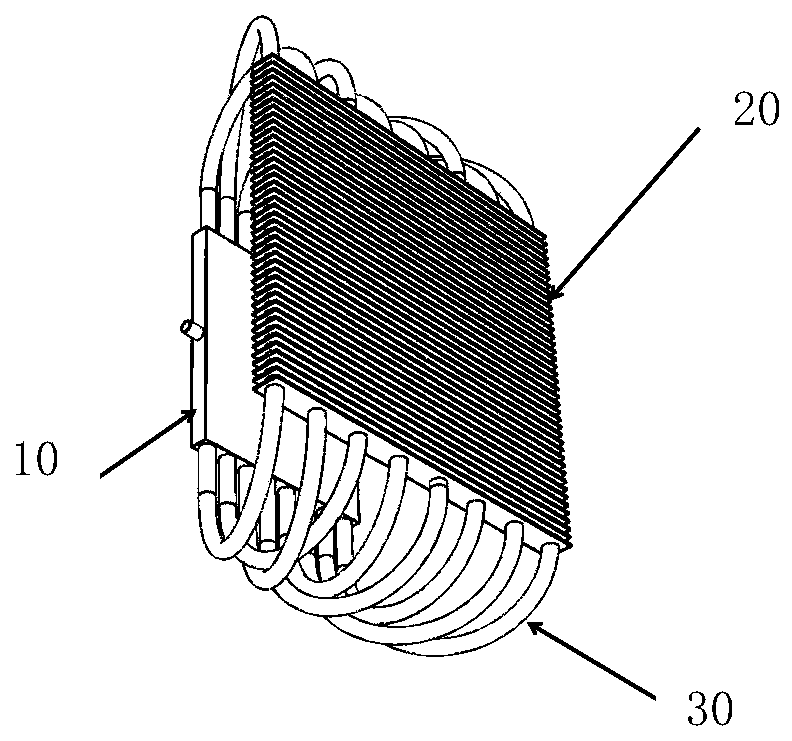

[0030] like figure 2 , image 3 As shown, the heat dissipation device with a three-dimensional pulsating heat pipe includes an evaporation unit 10 , a condensation unit 20 , an adiabatic unit 30 and a heat dissipation unit 40 .

[0031] like Figure 4 As shown, the evaporating unit 10 includes a plurality of evaporating pulsating heat pipes 11 arranged in a plane and an evaporating section 12 .

[0032] In the embodiment, the evaporating pulsating heat pipe 11 is made of red copper (or other materials) with good thermal conductivity and certain pressure bearing capacity.

[0033] The evaporating section 12 is planar. In the embodiment, the evaporating section 12 is made of a copper plate with good thermal conductivity, and a plurality of through holes are arranged in the thickness of the copper plate, and a plurality of evaporating pulsating heat pipes 11 pass through a plurality of through holes Set in copper plate. The liquid filling port 13 is placed on one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com