Porous sintering heat-insulating hollow block and manufacturing process thereof

A hollow block and process technology, which is applied in the field of porous sintered thermal insulation hollow block and its preparation technology, can solve the problems of poor safety, short life, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] The porous sintered insulating hollow block 68 of this embodiment is composed of the following components in weight percentage: 30% of solid waste, 55% of inorganic binder, and 15% of microporous pore-forming agent; the solid waste is coal gangue, and the The inorganic binder is shale (with a particle size less than 0.5mm), and the microporous pore-forming agent is sawdust.

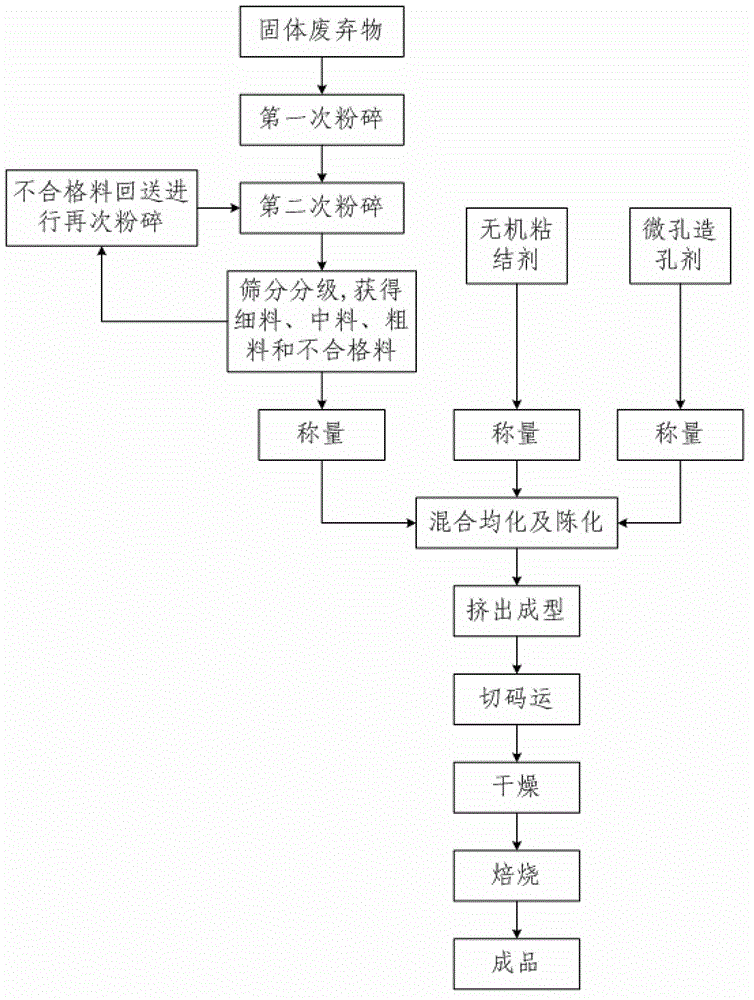

[0100] Such as figure 1 and figure 2 As shown, the preparation process of the present embodiment comprises the following steps:

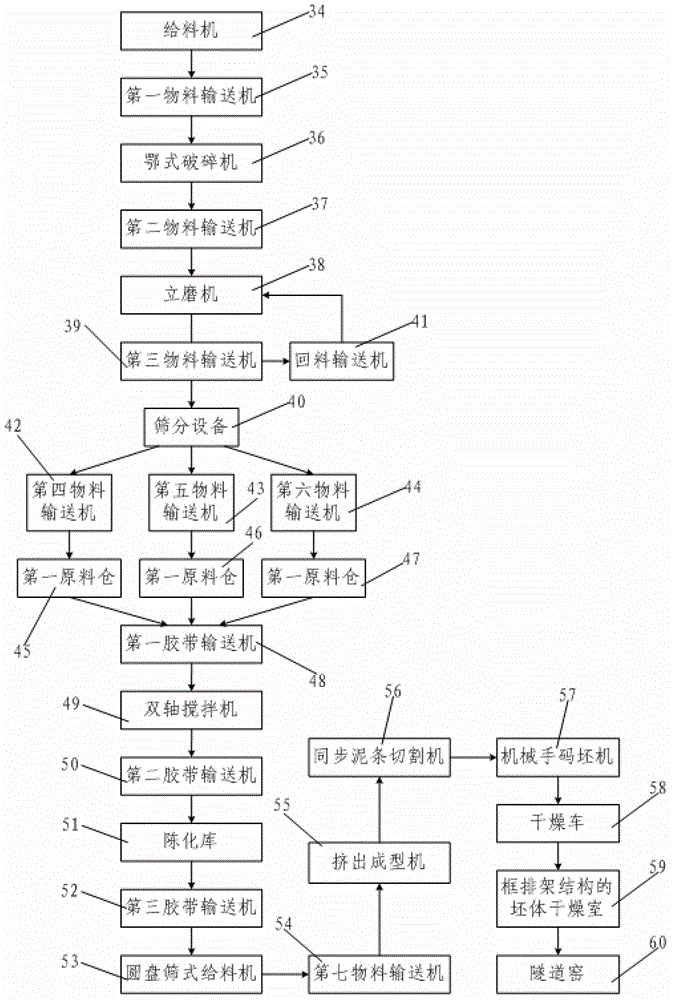

[0101] Step 1, particle grading: first, the first material conveyor 35 sends the solid waste in the feeder 34 to the jaw crusher 36; then, the jaw crusher 36 crushes the solid waste for the first time, The second material conveyor 37 sends the solid waste obtained by crushing for the first time to the vertical mill 38; then, the vertical mill 38 crushes the solid waste obtained for the first time for the second time, and the third material conveyor 39 Send the solid ...

Embodiment 2

[0126] The porous sintered heat-insulating hollow block 68 of this embodiment is composed of the following components by weight percentage: 33% of solid waste, 53% of inorganic binder, and 14% of microporous pore-forming agent; the solid waste is fly ash, and the The inorganic binder is river silt, and the microporous pore-forming agent is rice husk.

[0127] The difference between the preparation method of this embodiment and embodiment 1 is:

[0128] Step 3, raw material weighing: when the porous sintered insulating hollow block 68 to be prepared is a non-load-bearing insulating hollow block, the weight ratio of coarse material, medium material and fine material in the solid waste is 6:17: 72. When the porous sintered insulating hollow block 68 to be prepared is a load-bearing insulating hollow block, the weight ratio of coarse material, medium material and fine material in the solid waste is 1:11:85;

[0129] Step 4, mixing and homogenizing and aging: the primary mixture i...

Embodiment 3

[0133] The porous sintered insulating hollow block 68 of this embodiment is composed of the following components in weight percentage: 36% of solid waste, 51% of inorganic binder, and 13% of microporous pore-forming agent; the solid waste is steel slag, and the inorganic The binder is river mud, and the microporous pore-forming agent is polyphenylene particles. Among them, polyphenylene particles can be crushed from waste polyethylene foam.

[0134] The difference between the preparation method of this embodiment and embodiment 1 is:

[0135] Step 3, raw material weighing: when the porous sintered insulating hollow block 68 to be prepared is a non-load-bearing insulating hollow block, the weight ratio of coarse material, medium material and fine material in the solid waste is 8:15: 70; when the porous sintered insulating hollow block 68 to be prepared is a load-bearing insulating hollow block, the weight ratio of coarse material, medium material and fine material in the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com