A kind of drying chamber of sintered wall material green body with frame bent structure

A technology for wall materials and drying chambers, applied in the direction of progressive dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of low drying efficiency, green body regain, collapse, green body cracking, etc., and achieve novel structure , improve drying efficiency, and design reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

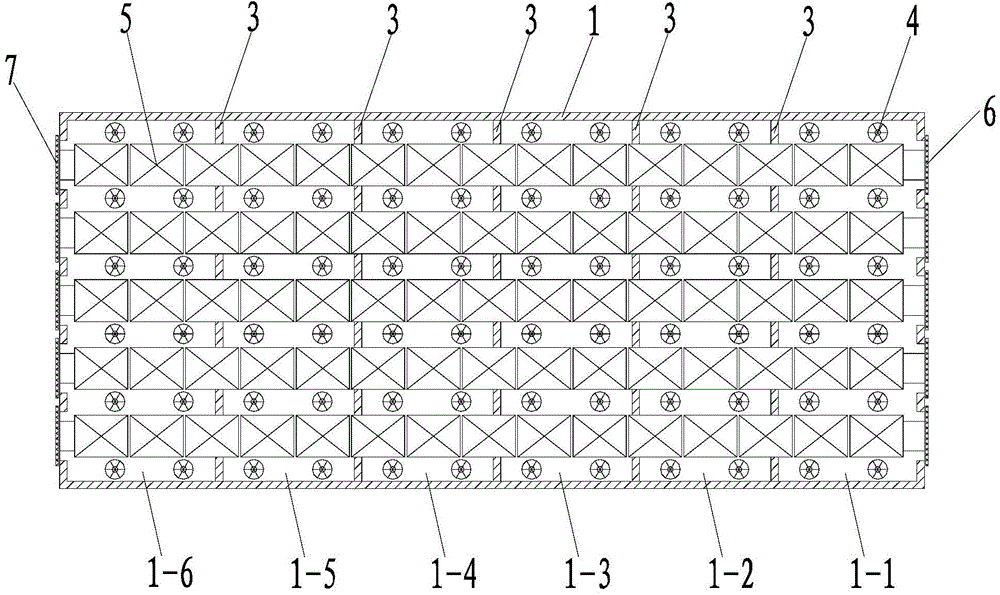

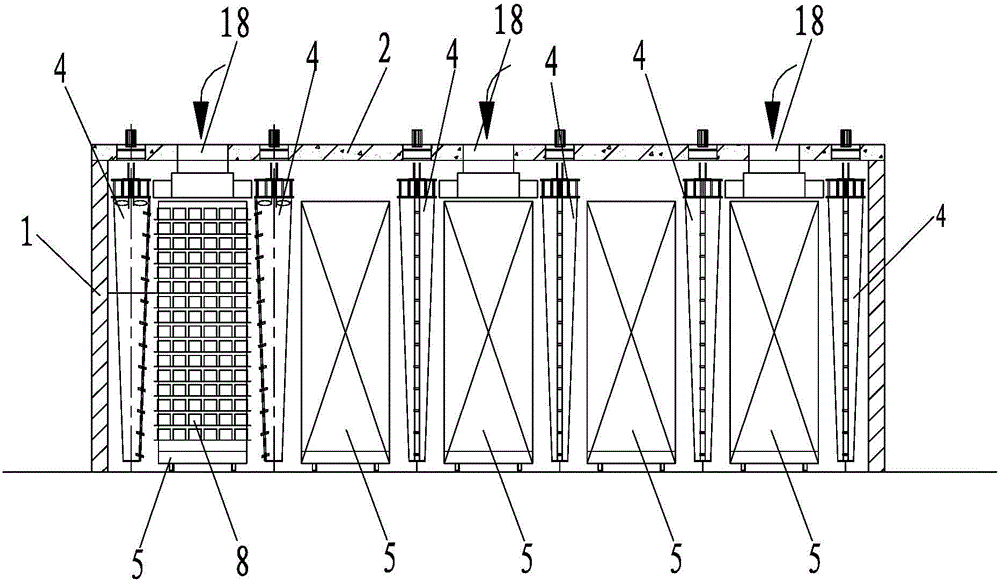

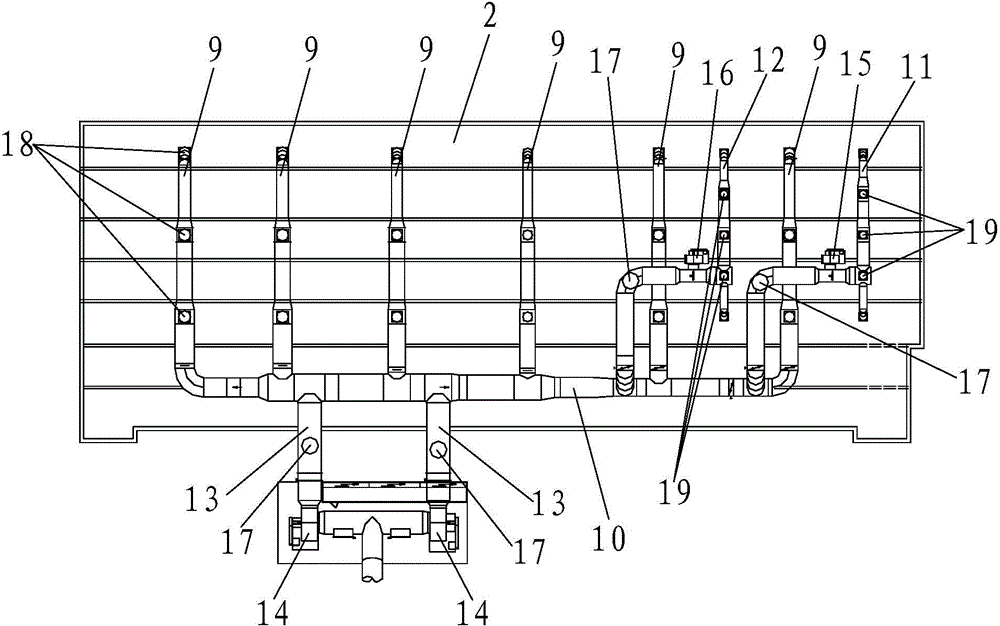

[0049] Such as Figure 1 to Figure 5 As shown, the present invention comprises a drying room main body, a drying room air supply system and a drying room automatic control system. The drying room main body includes a cube-shaped enclosure structure 1 and a drying chamber roof 2 arranged on the enclosure structure 1 top. There are multiple transverse partition walls 3 for separating the inner space of the enclosure structure 1 into a plurality of drying sections in the enclosure structure 1, and multiple columns are arranged longitudinally in the enclosure structure 1 for drying The rotary air blower 4 that blows the green body 8 intermittently, the passage between two adjacent rows of rotary air blowers 4 constitutes a drying lane for the drying vehicle 5 that is equipped with the green body 8 to be dried to pass through, and is aligned with the drying lane The two ends of the enclosure structure 1 are symmetrically provided with an entry door 6 and an exit door 7; the air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com