Pulsating heat pipe with tilt-angle communicating pipe structure

A technology of pulsating heat pipes and connecting pipes, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as affecting the normal operation and life of electronic components, difficulty in starting pulsating heat pipes, and reducing heat transfer characteristics, so as to avoid burning out. phenomenon, accelerated transfer, the effect of increasing the evaporation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

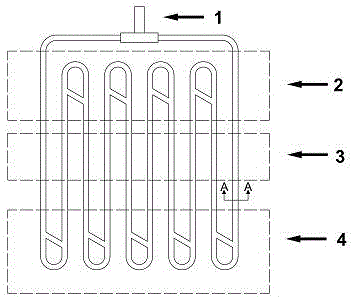

[0029] The pulsating heat pipe of the present invention includes a vacuum pumping / injecting working fluid section, an evaporation section with an oblique connecting pipe, an adiabatic section and a condensation section with an oblique connecting pipe;

[0030] The pulsating heat pipe is a closed-loop pulsating heat pipe;

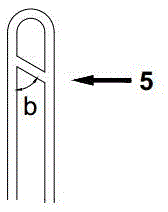

[0031] The evaporating section with oblique connecting pipe connects a connecting pipe with an angle to the straight pipe at the U-bend straight pipe of the traditional evaporating section to connect two adjacent straight pipes in the evaporation section;

[0032] The condensing section with oblique connecting pipe connects a connecting pipe with an angle to the straight pipe at the U-bend straight pipe of the traditional condensing section to connect two adjacent straight pipes in the condensing section;

[0033] The adiabatic section has the same pipe diameter as the evaporation section and the condensation section and is integrally formed;

[0034] The vacuum pumpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com