Impact-free interference removal high-precision gravimetric feeder

A feeder, high-precision technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as reduced efficiency, inaccurate measurement, and impact on weighing accuracy, so as to achieve reduced startup and operating power, Accurate weighing results and sensitive transmission of induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

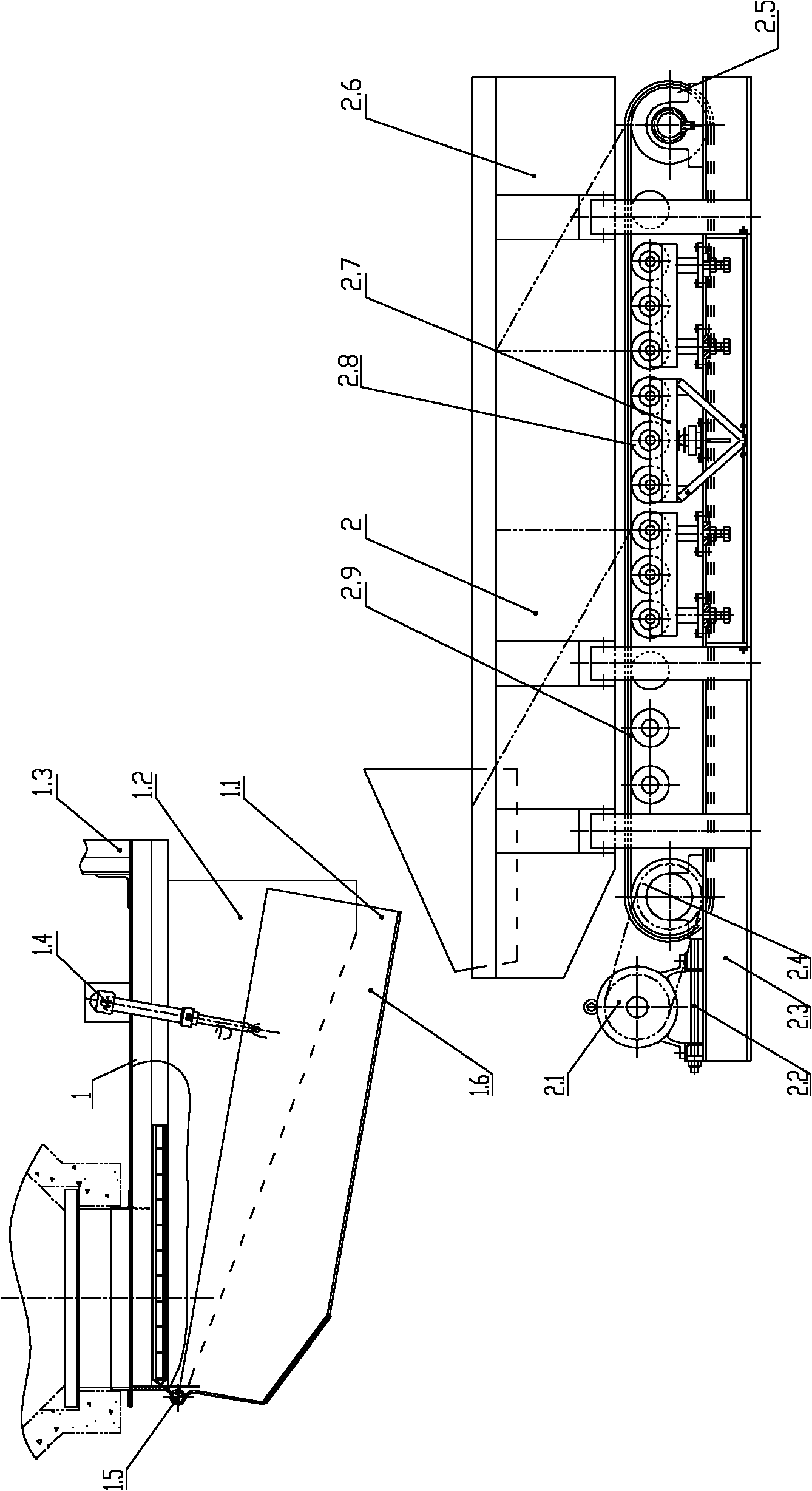

[0019] The impact-free and interference-free high-precision weight feeder includes a material receiving part 1 and a weight reloading part 2. The feeder consists of a material receiving part 1 and a reloading part 2, wherein the material receiving part 1 includes a collection hopper 1.1 and a material guide trough 1.2, and the material guide trough 1.2 is connected with the discharge port of the silo or the discharge port of other equipment. Feed trough 1.2 makes its position fixed by hanging 1.3. A variable inclination mechanism is set between the collecting hopper 1.1 and the material guide trough 1.2, such as figure 1 The hydraulic cylinder 1.4. The variable inclination mechanism can also be arranged on the bottom or side of the collecting hopper 1.1. A rotating mechanism 1.5 is provided at the joint between the collecting hopper 1.1 and the material guide groove 1.2, and the collecting hopper 1.1 can rotate along the rotating mechanism 1.5. When the material receiving p...

Embodiment 2

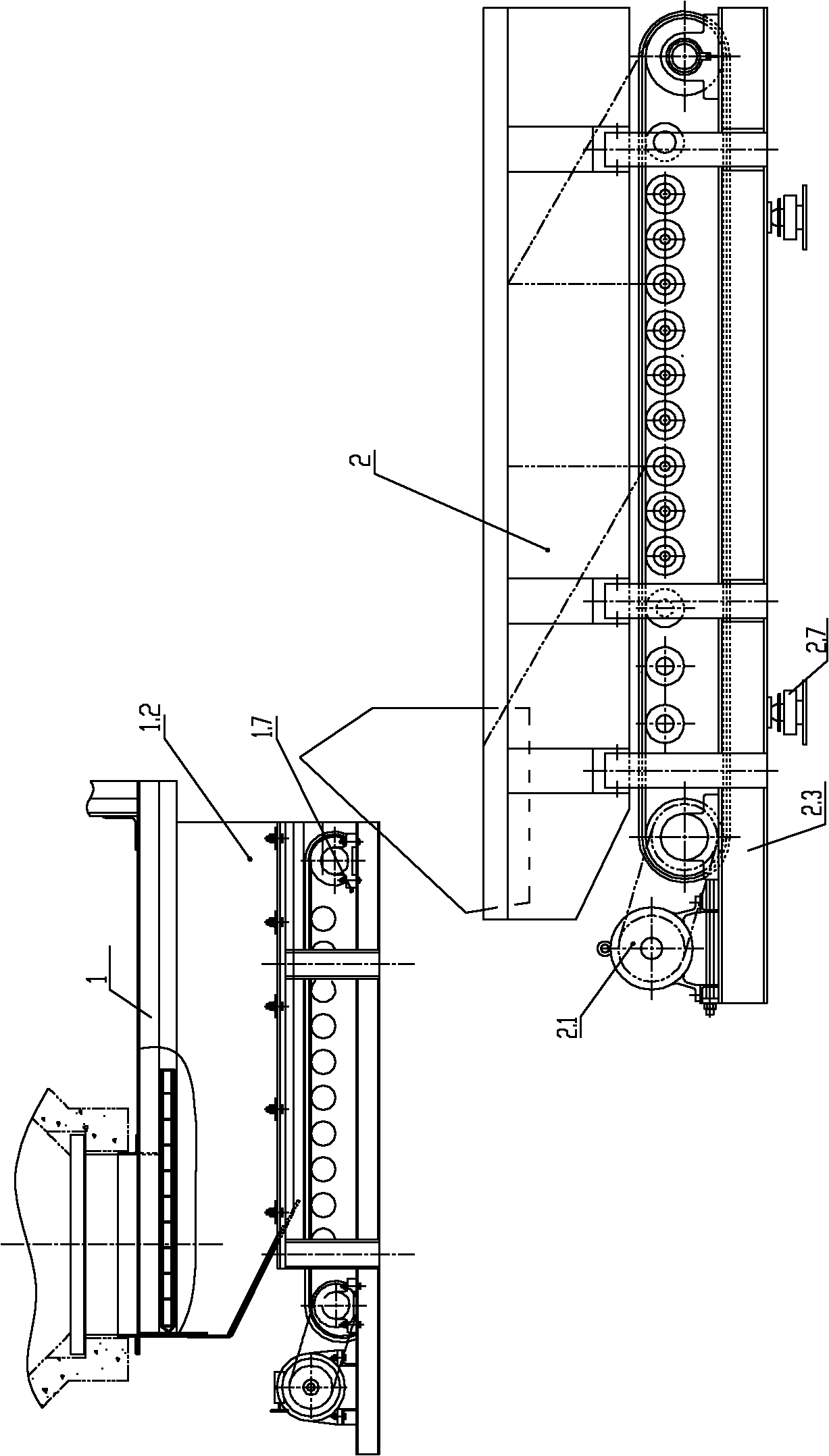

[0027] figure 2 It is the high-precision weighing feeder that avoids impact and eliminates interference described in embodiment 2. Different from Embodiment 1, the material receiving part 1 is a belt-type material receiving device, which includes a material guide 1.2 and a belt-type material receiving device 1.7, and the upper part of the material guide 1.2 is discharged from the outlet of the silo or other equipment. port connection, the bottom of the material guide trough 1.2 is connected with the belt-type material receiving device 1.7, and the material guide trough 1.2 and the belt-type material receiving device 1.7 form a box body. The belt receiving device includes a conveyor belt, driven by the conveyor belt, the material enters the reloading part.

[0028]The weighing and reloading part adopts a belt-type weighing and reloading mechanism, and the weighing sensor is set under the weighing roller and / or on the bottom surface of the reloading frame, which can be weighed...

Embodiment 3

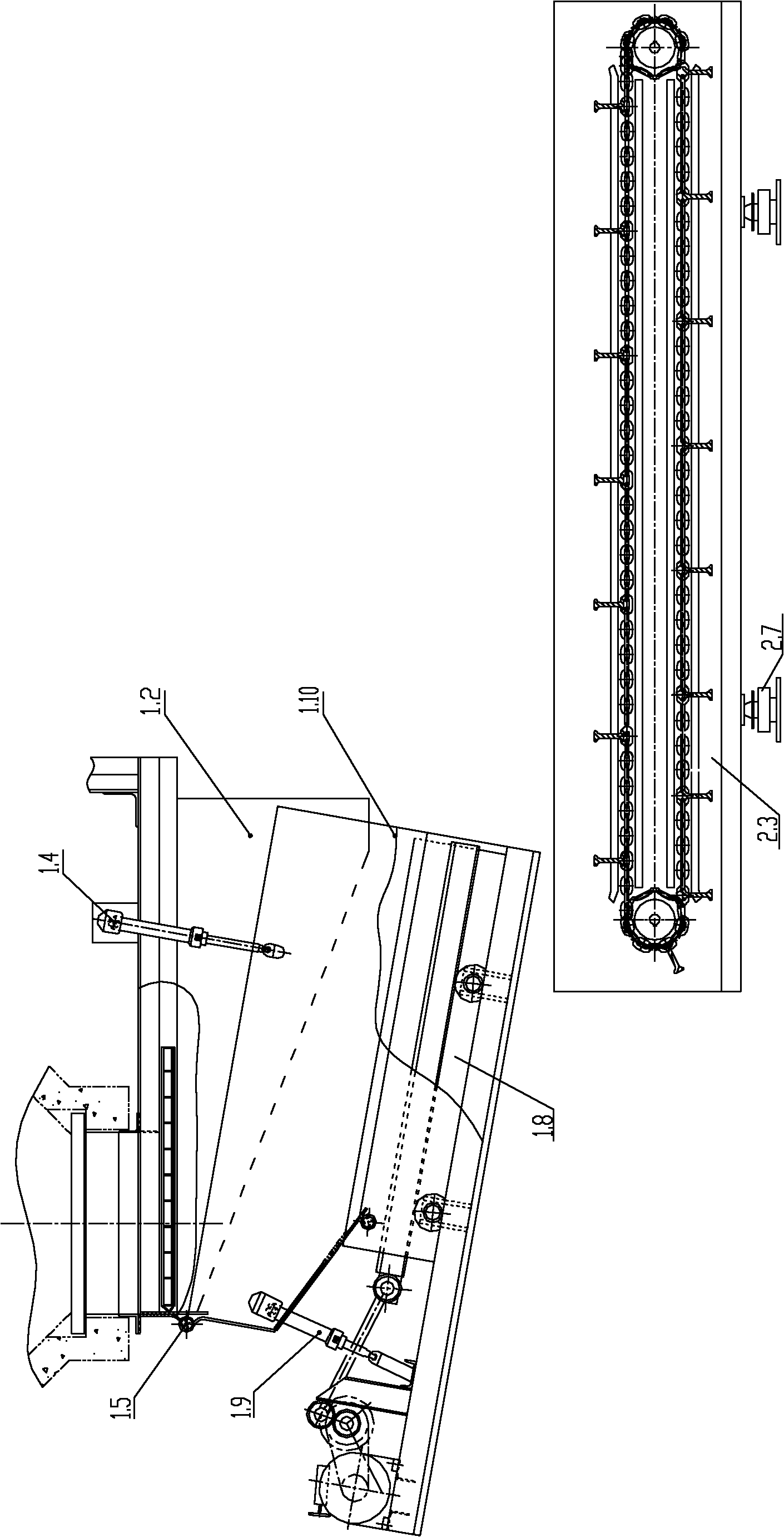

[0031] image 3 It is the high-precision weighing feeder that avoids impact and eliminates interference described in embodiment 3. The difference from Example 1 is that the material receiving part includes a collection tank 1.10, a material guide tank 1.2 and a reciprocating material receiving device 1.8, and the upper part of the material guide tank 1.2 is connected with the outlet of the silo or other equipment outlets, and the guide A variable inclination mechanism can be provided between the hopper 1.2 and the collection chute 1.10, such as image 3 The hydraulic cylinders shown, etc., are also equipped with hydraulic cylinders on the side of the collecting tank 1.10, so that the discharge port of the receiving part 1 is inclined downward at a certain angle when it is working, so that the material enters through the receiving part 1 smoothly and with the lowest drop. Weight Reproduced Part 2. The variable inclination mechanism also can adopt air cylinder, screw rod, rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com