Energy-saving environment-friendly polymer-based composite material matrix of diamond circular saw blade

A composite material, energy saving and environmental protection technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of high production costs, heavy diamond circular saw blades, and high power consumption of the saw blades, reducing the Starting power and its own power consumption, the characteristics of simple production process, the effect of energy saving and low carbon effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

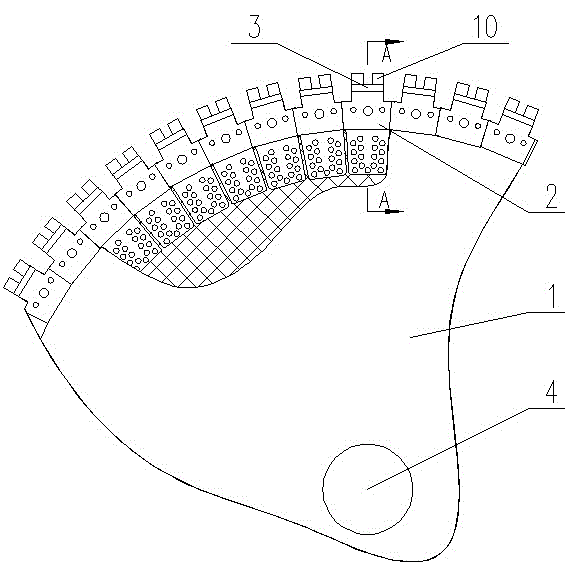

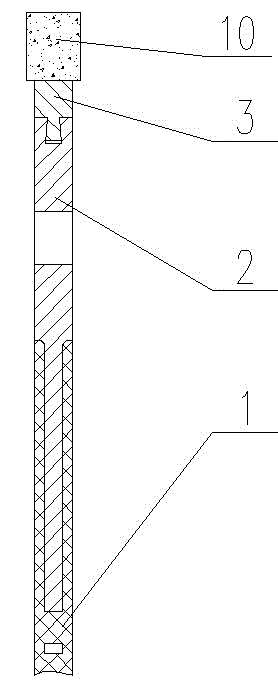

[0035] Such as Figure 1-8 As shown, the embedded part of the insert 2 is processed with many process through holes 5, and these process through holes 5 play a role in strengthening the connection of the insert 2; the section of the tenon groove 13 of the exposed part of the insert 2 is trapezoidal in the height direction and the length direction , the included angle of the trapezoid in the height direction is 8°, the included angle of the trapezoid in the length direction is 4°, and the shape of the tenon 3 matches the tenon groove 13 on the insert 2. The insert 2 is firmly embedded on the unsaturated polyester resin matrix 1 with a central hole 4 by hot casting. Since the embedded part of the insert 2 is processed with many process through holes 5, the material of the base body 1 can penetrate through the process through holes 5 to be connected with each other during hot casting, so as to enhance the firmness of the connection.

[0036] When in use, the diamond saw teeth 10...

Embodiment 2

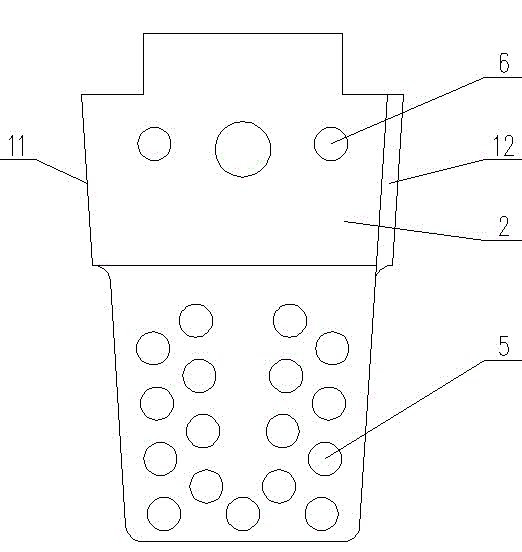

[0038] Such as Figure 9-13 As shown, the embedded part of the insert 14 is processed with several process through holes 8, and these process through holes 8 play a role in strengthening the connection of the insert 14; the insert 14 is firmly embedded in the polypropylene matrix with a central hole by hot casting 9, there is a concave land 11 on the left and right sides of the exposed part, and the convex lands 12 cooperate with each other to prevent the axial movement of the insert 14 caused by long-term vibration in the axial direction of the base 9; the exposed part is processed with Several through holes 6, these through holes 6 can play the role of ventilation and heat insulation when the diamond saw teeth are welded. There are two sawtooths 7 on the top of the exposed part, and the length and size of each sawtooth 7 are significantly reduced, but the number of sawtooths on the entire base 9 is increased. This method of short teeth and multiple numbers effectively improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com